- Product Details

- {{item.text}}

Quick Details

-

Cost:

-

Small investments

-

Type:

-

Simple dry mortar production line

-

Keyword:

-

Dry Powder Mortar Mixing Plant

-

Mixer type:

-

Double Paddle Shafts Mixer

-

End Product1:

-

tile adhesive mortar,wall putty mortar,skim coat mortar,

-

End Product2:

-

anti-crack mortar,waterproof mortar,self levelling, tile grout mortar

-

Advantage:

-

Professional Manufacture

-

Application scope:

-

Building material Industry

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

BH Complete specification epoxy mortar mixer for sale

-

Production Capacity:

-

3T/H

-

Cost:

-

Small investments

-

Type:

-

Simple dry mortar production line

-

Keyword:

-

Dry Powder Mortar Mixing Plant

-

Mixer type:

-

Double Paddle Shafts Mixer

-

End Product1:

-

tile adhesive mortar,wall putty mortar,skim coat mortar,

-

End Product2:

-

anti-crack mortar,waterproof mortar,self levelling, tile grout mortar

-

Advantage:

-

Professional Manufacture

-

Application scope:

-

Building material Industry

BH Complete specification epoxy mortar mixer for sale

| Description of BH Simple dry mortar plant |

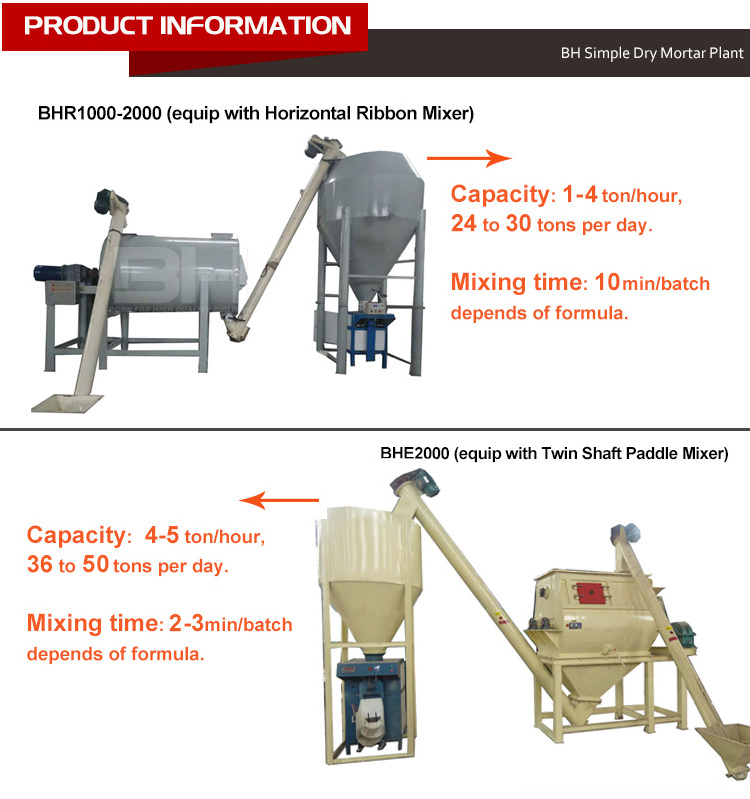

BH simple dry mortar plant can equip with two kinds of mixers,horizontal ribbon mixer and twin shaft paddle mixer according to customer requested capacity and actual workshop height condition. 1-4t/h BHR series simple dry mortar plant usually equip with horizontal ribbon mixer, 4-5t/h BHE2000 simple dry mortar plant usually equip with twin shaft paddle mixer.Both these two mixer machine can produce Putty powder, Tile adhesives,tile glue, Thin set coating, Masonry mortar, Plaster mortar, Screed mortar,Bonding mortar,AAC jointing mortar, dry sand mixture, Insulation mortar,Decoration mortar and etc.

BH Simple dry mortar plant features

1. BHR series Horizontal ribbon mixer plant height is less than 3.2 meters, BHE series twin shaft paddle mixer plant height is less than 4.2 meters, both occupation area 15~ 20 square metres , ordinary houses can be use as factory production, this solve the problems of traditional dry mortar production line has to increase height of factory.

2. It achieve function of manual batching raw materials, automatic mixing, automatic filling and packing at 15-50kg/bag , under a small investment, and less labor.

3. It is one of the most simple and practical dry mortar production line.

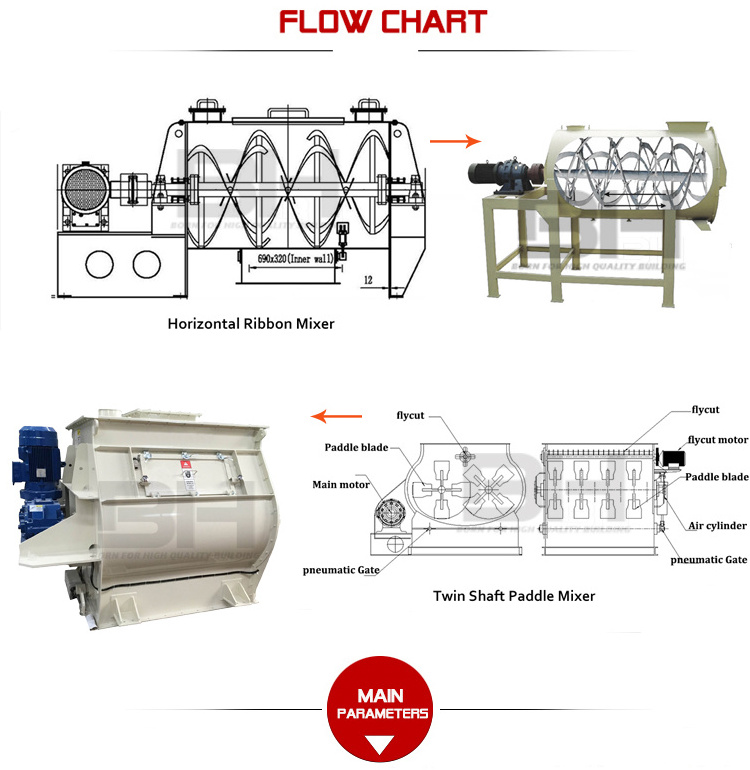

BH Horizontal Ribbon Mixer Working principle:

The outer and inner screw ribbon blade driven by high speed rotating shaft,mixing the material in maximum,inner screw ribbon blade forced the material to sides,outer screw ribbon blade forced sides material to inward,mix the materials back and forth.In the same time,some material driven by screw ribbon do the radial motion,to form the convective mixing,so to achieve uniform mixing effect in relatively short time.

BH Twin Shaft Paddle Mixer Working principle:

The high efficiency twin shaft mixer adopts the paddle structure,The materials can lose weight instantly at the critical parabolic rotate speed so that can achieve best mixing effect,while the violent turnover speed shortens the mixing time in large extent,Thus the mixer is widely applied in medium and large dry mortar production lines

|

||||

| Model | Simple dry mortar plant | Improved Simple dry mortar plant | Semi automatic dry mortar plant | Full automatic dry mortar plant |

| Out put | 1-3t/h | 4-5t/h | 5-8t/h | 10-30t/h |

| Components |

screw conveyor, horizontal ribbon mixer, storage tank, packing machine, control cabinet, air compressor |

screw conveyor, twin shaft mixer, storage tank, packing machine, control cabinet, air compressor | bucket elevator, twin shaft mixer, holding tank, packing machine, control cabinet, air compressor | cement silo, screw conveyor, automatic weighing system, bucket elevator, premix tank, twin shaft mixer, holding tank, packing machine, automatic control cabinet, air compressor |

| Occupied area | 20m² | 20 m² | 50-60 m² | 60-100 m² |

| Total power | 5.5-7.5kw | 6-11kw | 24-28kw | 60-120kw |

|

Mixer volume |

3300*1050*2100(mm) | 2m³ | 2 m³ | 2 m³ , 3 m³ , 4 m³ |

| Equipment height | 3-4m | 3-4m | 6-8m | 8-13m |

| Man power | 2-3person | 2-3person | 3-4person | 3-4person |

| Batching and packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Automatic batching & Automatic packaging |

| MAIN PARTS FEATURES |

|

Horizontal Ribbon Mixer

1.Occupy area<20m2,height 3.5m,required 2-3 operation.

|

|

|

Twin Shaft Paddle Mixer 1. High mixing homogeneity at 99.9% 2. High efficiency at 90~120 seconds per batch 3. No dead corner for mixing. No residual for discharging 4. Durable lifetime and stable performance. |

|

|

Packing Machine

|

|

|

Screw conveyor

|