- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6KW

-

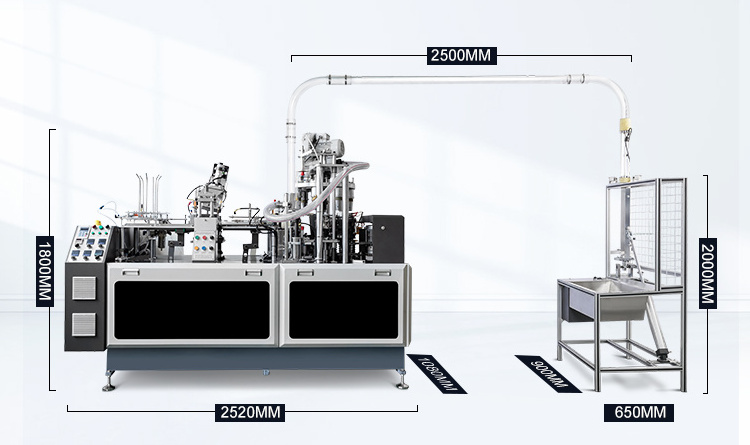

Dimension(L*W*H):

-

2520*1080*1800mm.

-

Weight:

-

1800 kg

-

Marketing Type:

-

New Product 2023

-

Suitable Paper Weight:

-

140-350gsm

-

Rated Productivity:

-

100-110 pcs/min

-

GW/NW:

-

1800KGS/1700KGS

-

Package Size:

-

2520*1080*1800mm.

-

Cup Side Welding:

-

Copper Heater or Ultrasonic heater

-

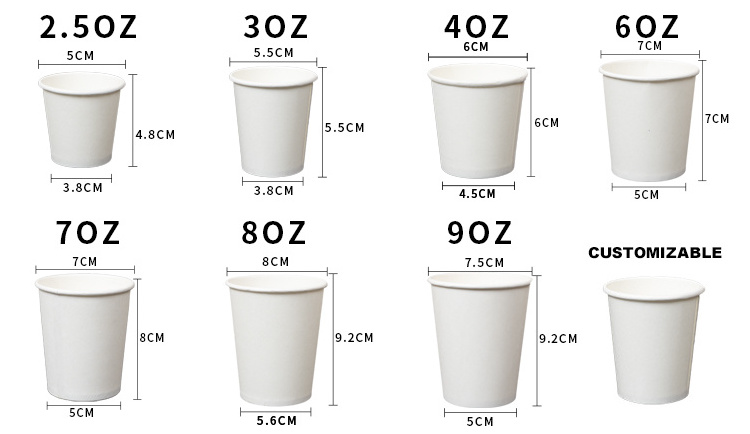

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould exchangeable)

-

Raw Material:

-

One or Two side PE coated Paper

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Production Capacity:

-

100-110 pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2520*1080*1800mm.

-

Weight:

-

1800 kg

-

Marketing Type:

-

New Product 2023

-

Suitable Paper Weight:

-

140-350gsm

-

Rated Productivity:

-

100-110 pcs/min

-

GW/NW:

-

1800KGS/1700KGS

-

Package Size:

-

2520*1080*1800mm.

-

Cup Side Welding:

-

Copper Heater or Ultrasonic heater

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould exchangeable)

-

Raw Material:

-

One or Two side PE coated Paper

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Paper Cup Size

Products Description

1.High-speed production capacity:

It can produce 100-110 cups per minute

, improving production efficiency.

2.Multiple size applicability:

Suitable for producing cups ranging from 2 to 16 ounces

, meeting various size requirements.

3.Wide applicability: Suitable for producing various types of paper cups, including hot drinks, cold drinks, coffee, tea, and ice cream cups.

|

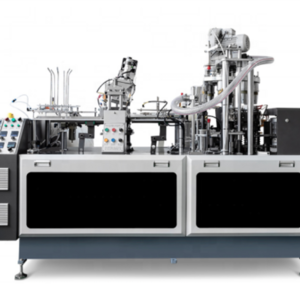

Model

|

High Speed Single Plate Open Cam Paper Cup Machine MYC-OCM12

|

|

|

|

||||

|

Paper Cup Size

|

2 ~16 OZ (Mould exchangeable, Max Cup Height:135mm , Max Bottom width :70mm

|

|

|

|

||||

|

Rated Speed

|

100-110pcs/min ( Speed affected by cup size, paper quality & thickness), 9OZ, 280GSM paper cup Stable running speed 100-110 pcs each min

|

|

|

|

||||

|

Raw Material

|

One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

|

|

|

|

||||

|

Suitable paper weight

|

140-350gsm

|

|

|

|

||||

|

Power Source

|

50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power.requirement

|

|

|

|

||||

|

Total Power

|

6KW

|

|

|

|

||||

|

Total Weight

|

GW/NW: 1800KGS/1700KGS

|

|

|

|

||||

|

Pack Size (L*W*H)

|

2100*970*1700mm(Machine Packing Size), 1250*860*1860MM(Counting Machine Packing Size)

|

|

|

|

||||

|

Working Air Source

|

Air pressure:0.4Mpa;

Air Out-put:0.6m³/minute Need to buy Air Compressor(by user) |

|

|

|

||||

|

Cup Side Welding

|

Ultrasonic heater

|

|

|

|

||||

|

Cup Bottom Heating

|

1side PE paper by heater knurling;

2side PE paper by cool device (circle water) knurling |

|

|

|

||||

|

Cup Bottom Knurling

|

Heater Knurling (if use single PE coated paper)

|

|

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

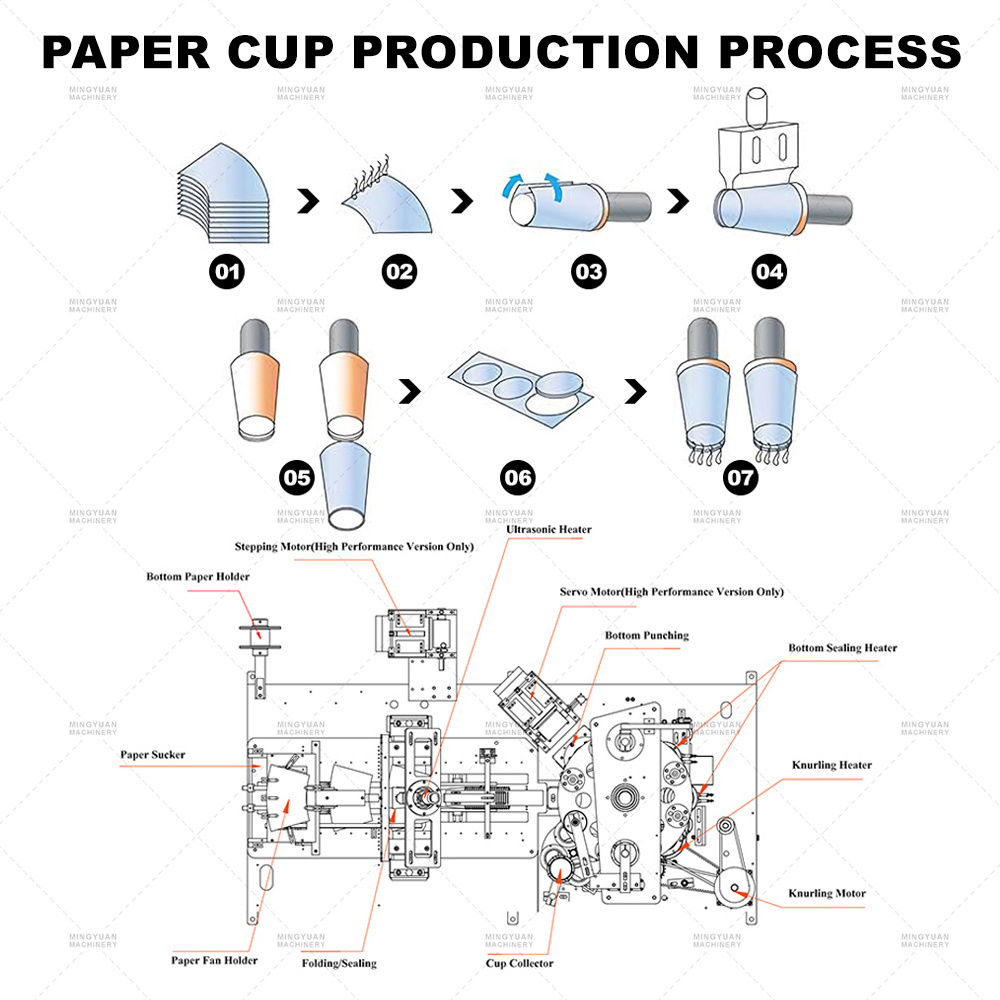

Production Flow

Product Details

1

.A

ir flier tank :

make the air dryer withour water into solenoid valve,longer service life

2

.

Vacuum generator :

Sucking down paper fan easily , more stable and durable

3

.

Ultrasonic system :

paper fan side sealing

4.

bottom paper steel roller :

bottom roll feeding , more durable, less wear and tear trouble compared with rubber

5.

12 Sensors :

detection and send the alarm when machine has any failure

6.

Cup bottom heater :

preheat cup bottom and seal the cup bottom easily without leakage issues

7.

bottom knurling & top curling :

bottom knurling sealing ; top curling make the rim stronger and better

8.

25MM thickness stainless steel plate:

More Dura

ble and heavier , no shaking issue when machine running

9.

multifunctional Solenoid valve :

Control pneumatic components work more stable and longer service life

Long-term Cooperation Brand

Hot Searches