- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

25068-38-6

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FONG YONG

-

Model Number:

-

E-766B/H-766

-

Type:

-

Two Component

-

Viscosity(25 degree C, cps):

-

Part A: 3000-4500, Part B: 100-200

-

Mixing ratio:

-

100:30 by weight

-

Color:

-

Black

-

Product name:

-

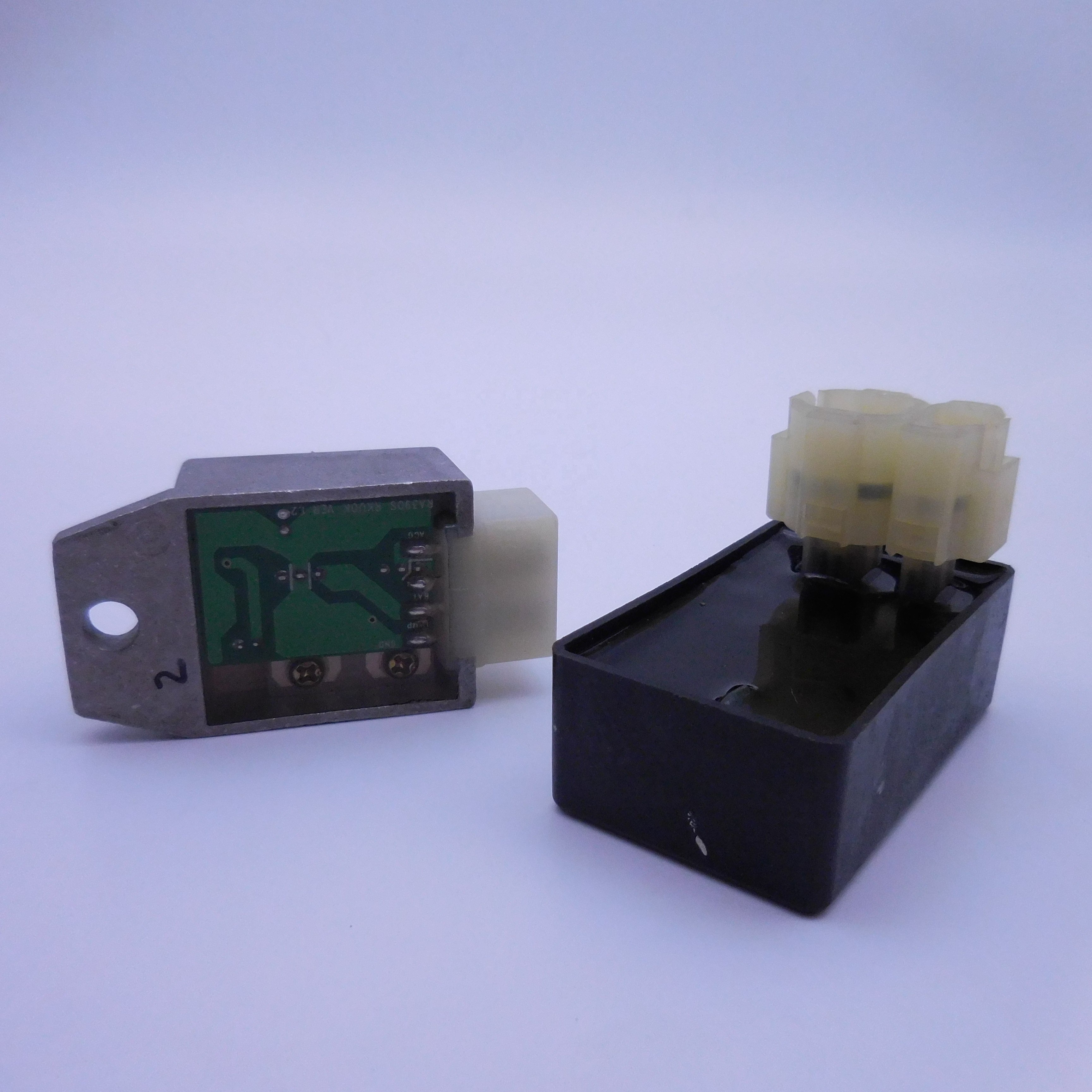

epoxy potting compound for motorcycle

-

Application:

-

potting casting

-

Name:

-

epoxy resin

-

Keywords:

-

ab glue

-

Material:

-

epoxy

-

Certificate:

-

RoHS, REACH, ISO-9000

-

Appearance:

-

Black liquid

Quick Details

-

CAS No.:

-

25068-38-6

-

Other Names:

-

potting compounds

-

MF:

-

epoxy

-

EINECS No.:

-

25068-38-6

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FONG YONG

-

Model Number:

-

E-766B/H-766

-

Type:

-

Two Component

-

Viscosity(25 degree C, cps):

-

Part A: 3000-4500, Part B: 100-200

-

Mixing ratio:

-

100:30 by weight

-

Color:

-

Black

-

Product name:

-

epoxy potting compound for motorcycle

-

Application:

-

potting casting

-

Name:

-

epoxy resin

-

Keywords:

-

ab glue

-

Material:

-

epoxy

-

Certificate:

-

RoHS, REACH, ISO-9000

-

Appearance:

-

Black liquid

Low cost good leveling flexible electronic potting epoxy resin ab glue manufacturer for electronic components

Professional formulator and manufacturer of pottings and encapsulations for electronic componen

Fong Yong 's potting and encapsulating compounds consists of epoxies and silicones systems. Our products feature outstanding electrical insulation properties, superior adhesive strength, thermal conductivity and excellent chemical resistance. Fong Yong 's potting and encapsulating compounds provide reliable long term performance for microelectronic, electronic, electrical devices, components including:

· Power supplies

· Switches

· Ignition coils

· Electronic modules

· Motors

· Connectors

· Sensors

· Cable harness assemblies

· Capacitors

· Transformers

· Rectifiers

Fong Yong potting, encapsulation, casting materials are impermeable to harsh environmental conditions. Our products offer the following advantages:

· Enhanced thermal management properties

· Crack resistance

· Protection against corrosion

· Elevated temperature and cryogenic serviceability

· Withstand rigorous thermal cycling and shock

We supply our potting and encapsulating compounds with wide range of viscosity, hardness, temperature resistance and thermal conductivities to meet full requirements among customers. Cure at ambient temperature or elevated temperature are both available. Some of them are UL-94v0 flammable retardant grade. Most of our products are RoHS, SVHC compliance. Standard products and custom-made products are all available. Our strong R&D and sales teams are ready to support our customers to make their products with best performance.

Description:

E-766B/H-766 is two parts epoxy resin. It is designed for protecting sensitive electronic components from impact, shock, vibration, heat, conductivity, moisture, chemical and visual inspection.

Features:

1. Low cost.

2. Low viscosity, no volatile, easy to use.

3. Low internal stress during curing process. It’s useful for delicate electrical and electronic components potting.

4. Good adhesive strength.

5. Excellent chemical resistance and water proofing.

Typical Properties:

E-766B H-766

Appearance Black or clear liquid Clear liquid

Specific Gravity (25 ℃ ) 1.02 0.97

Viscosity (25 ℃ ) 3,000-4,500 100-200

Mixing Information:

Ratio by weight 100 : 30

Curing :

Pot life (25 ℃ , 100g) 1 hour

Curing time - Room Temperature: 10 – 24 hours (follow the thickness of the film), or

- 50 ℃ ×2 hours + 80 ℃ × 2 hours

Typical Physical Properties:

Dielectric Constant 4.3

Dielectric Strength (v/mil) 430

Volume R esistivity (ohm-cm) 10 .0 ×10 1 5 (F)

Hardness (25 ℃ , shore A) 34

How to Use:

1. Thoroughly stir E-766B (black color) before use.

2. Prepare dry and clean container and mixer.

3. Based on the required quantities, mix resin ( E- 766B) and hardener (H- 766 ) at a ratio of 100:30 by weight.

4. Thoroughly mix the resin and hardener (Scrape down mixtures out the container wall, and mix well again).

5. Vacuum to de-air.

6. Apply the mixture into the objects.

7. Let cure at room temperature, or heat cure at an curing oven.