- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

China

-

Weight (KG):

-

50 KG

-

Product name:

-

Fiber Laser Cleaning Machine

-

Application:

-

Surface Paint Cleaning

-

Function:

-

Metal Rust Surface Laser Cleaning

-

Laser Power:

-

100W 200W 300W 500W

-

Keywords:

-

CNC Fiber Laser Cleaning

-

Cleaning Process:

-

Non-contact Laser Cleaning

-

Laser source:

-

Raycus MAX

-

Cooling method:

-

Air/Water Cooling System

-

Material:

-

Rust Oxide Painting Powder Coating

-

Feature:

-

Quick Speed High Accuracy

Quick Details

-

Power:

-

200W, 100W, 500W, 300w

-

Laser Type:

-

Fiber Laser

-

Laser Source Brand:

-

RAYCUS

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

China

-

Weight (KG):

-

50 KG

-

Product name:

-

Fiber Laser Cleaning Machine

-

Application:

-

Surface Paint Cleaning

-

Function:

-

Metal Rust Surface Laser Cleaning

-

Laser Power:

-

100W 200W 300W 500W

-

Keywords:

-

CNC Fiber Laser Cleaning

-

Cleaning Process:

-

Non-contact Laser Cleaning

-

Laser source:

-

Raycus MAX

-

Cooling method:

-

Air/Water Cooling System

-

Material:

-

Rust Oxide Painting Powder Coating

-

Feature:

-

Quick Speed High Accuracy

2023 hot sales of dry ice blasting machine laser cleaning machine working for rust paint oil and microelectronic field mold

Product Description

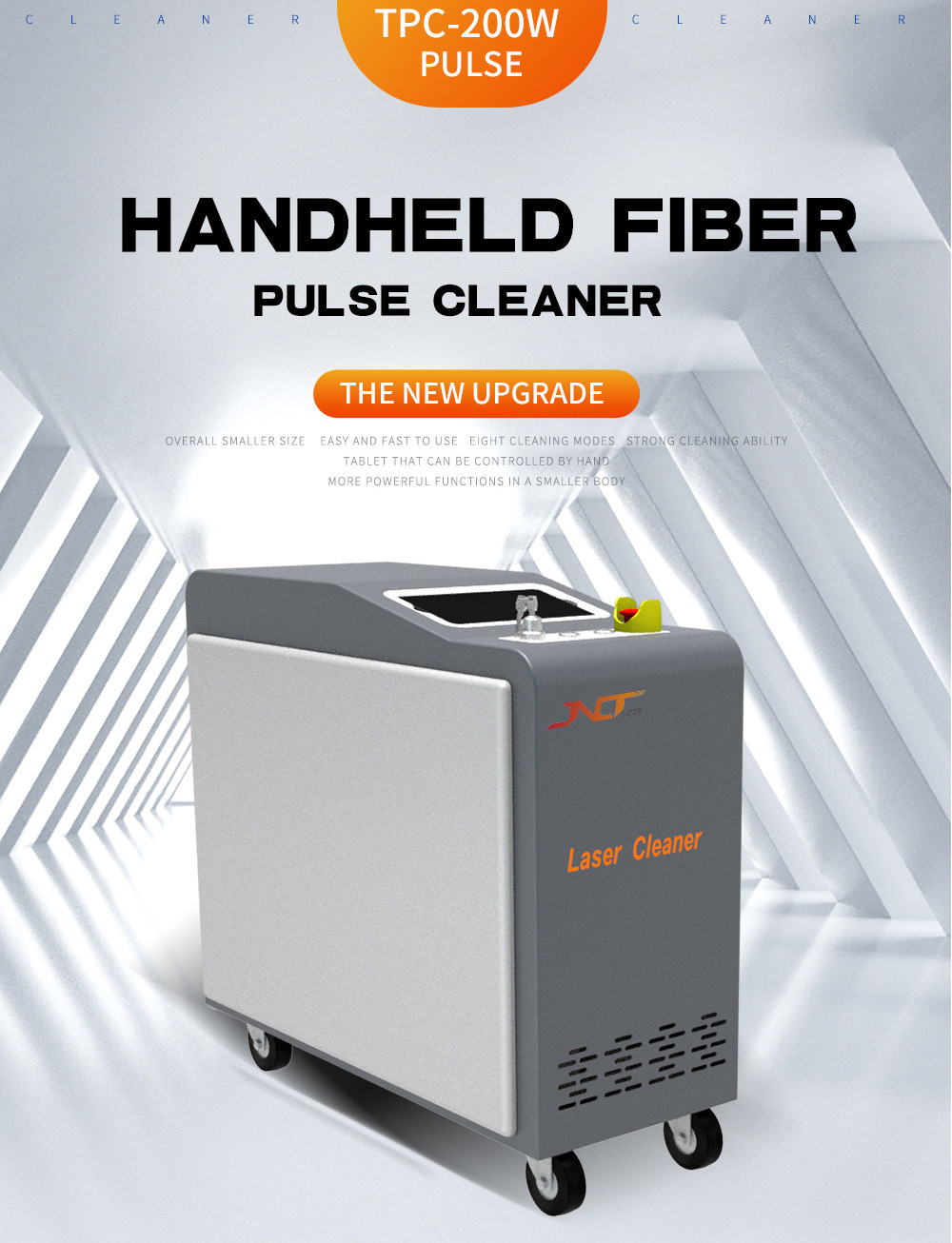

The 200w laser cleaner size is small, easy to use and handle.It also has eight cleaning modes, and the strong cleaning ability will help you to clean up everything around your house within seconds. With one simple click, you can get rid of dust, remove stains paint removal.

Moreover, this 200w laser cleaning machine device is equipped with a tablet that can be controlled by hand, which totally contains more powerful functions in a smaller body.

PRODUCT PARAMETERS

|

Maximum output power

|

200w

|

|

Maximum single pulse energy

|

1.8mj

|

|

Scan width (mm)

|

100/175 (other optional)

|

|

Power adjustment range(%)

|

10-100

|

|

Output power instability(%)

|

≤5

|

|

Fiber length(m)

|

4 (maximum 10 m)

|

MACHINE DISPLAY

Advantage of laser cleaning machine

1. Non-contact cleaning, do not damage the parts substrate.

2. Precise cleaning, can achieve precise position, precise size selective cleaning.

3. No chemical cleaning solution is needed, no consumables, safe and environmental protection.

4. Simple operation, electricity can be, can be hand-held or cooperate with the manipulator to realize automatic cleaning.

5. Cleaning efficiency is very high, saving time.

6. Laser cleaning system is stable, almost no maintenance.

7. One-time investment, economic efficiency.

Sample

1. Paint removal, rust removal: aircraft, ships, weapons equipment, Bridges, metal pressure vessels, metal pipes, etc. Aircraft parts, electrical parts, etc.

2. Mold cleaning: rubber mold, composite mold, metal mold, etc.

3. Surface treatment: hydrophilic treatment, treatment of weld before and after welding, etc.

4. Cultural relics protection: stone carving, bronze ware, glass, oil painting and murals, etc.

5. Microelectronics: semiconductor components, microelectronics devices, memory templates, etc.

6. Others: urban graffiti, printing roller, building exterior wall, nuclear industry, etc.

Packing & Delivery

Inner packing: elastic film and moisture-proof plastic film. Avoid all damage that may occur during delivery. The packing materials we use are waterproof and rust proof.Outside packing: We use standard plywood case. Then, to transport machine by air or by ship.

Hot Searches