- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongbang

-

Model Number:

-

hb

-

Surface Treatment:

-

Smooth, gritted or customized

-

Product name:

-

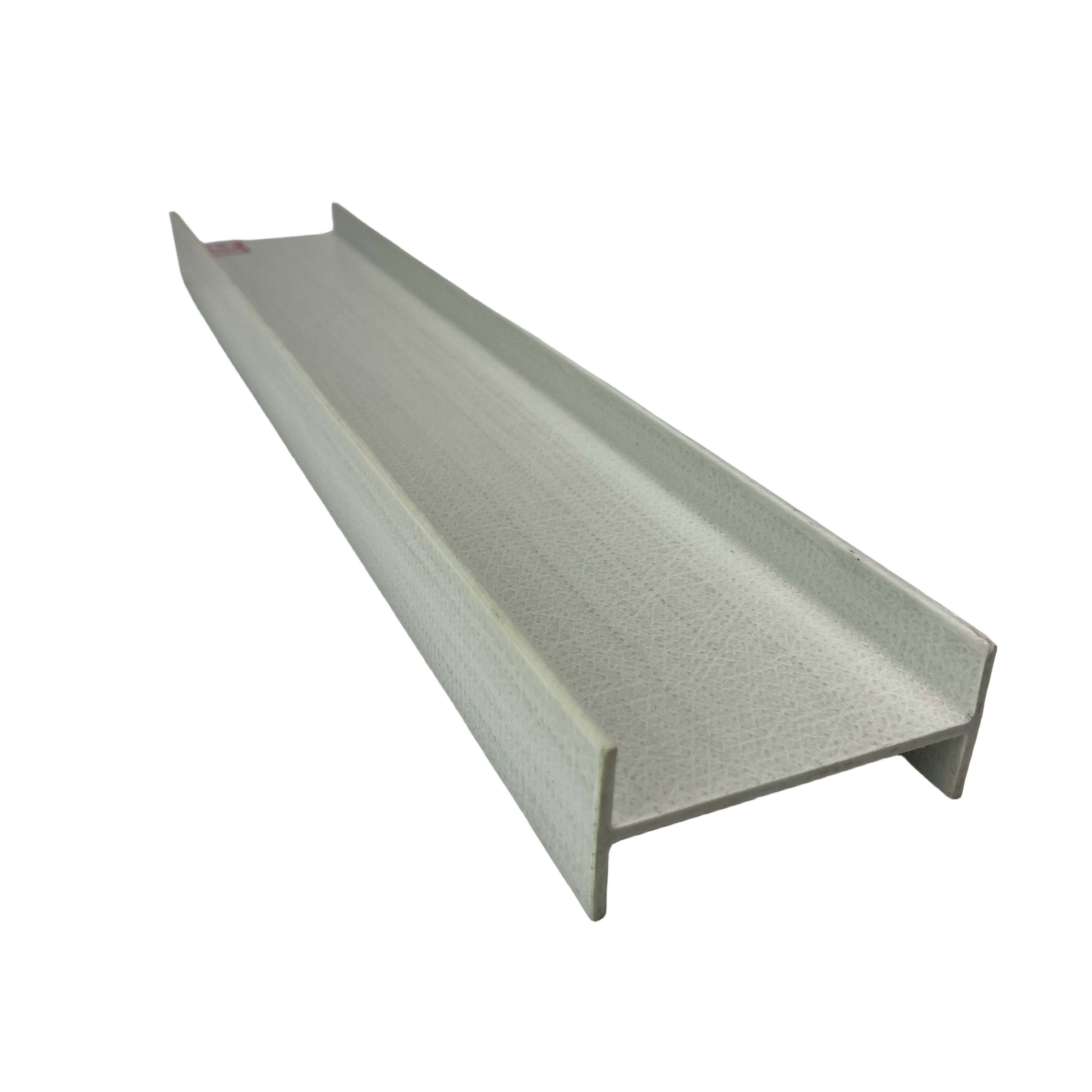

FRP channel

-

Material:

-

Fiberglass, Resin, Felt

-

Size:

-

Customized

-

Feature:

-

Corrosion Resistance

-

Color:

-

Any color

-

Drawings:

-

OK

-

Factory:

-

Yes

-

Sample:

-

Free

-

Length:

-

Specific Length Required

-

Bend:

-

Yes

Quick Details

-

Application:

-

framework

-

Technique:

-

Pultrusion process

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hongbang

-

Model Number:

-

hb

-

Surface Treatment:

-

Smooth, gritted or customized

-

Product name:

-

FRP channel

-

Material:

-

Fiberglass, Resin, Felt

-

Size:

-

Customized

-

Feature:

-

Corrosion Resistance

-

Color:

-

Any color

-

Drawings:

-

OK

-

Factory:

-

Yes

-

Sample:

-

Free

-

Length:

-

Specific Length Required

-

Bend:

-

Yes

Product Description

|

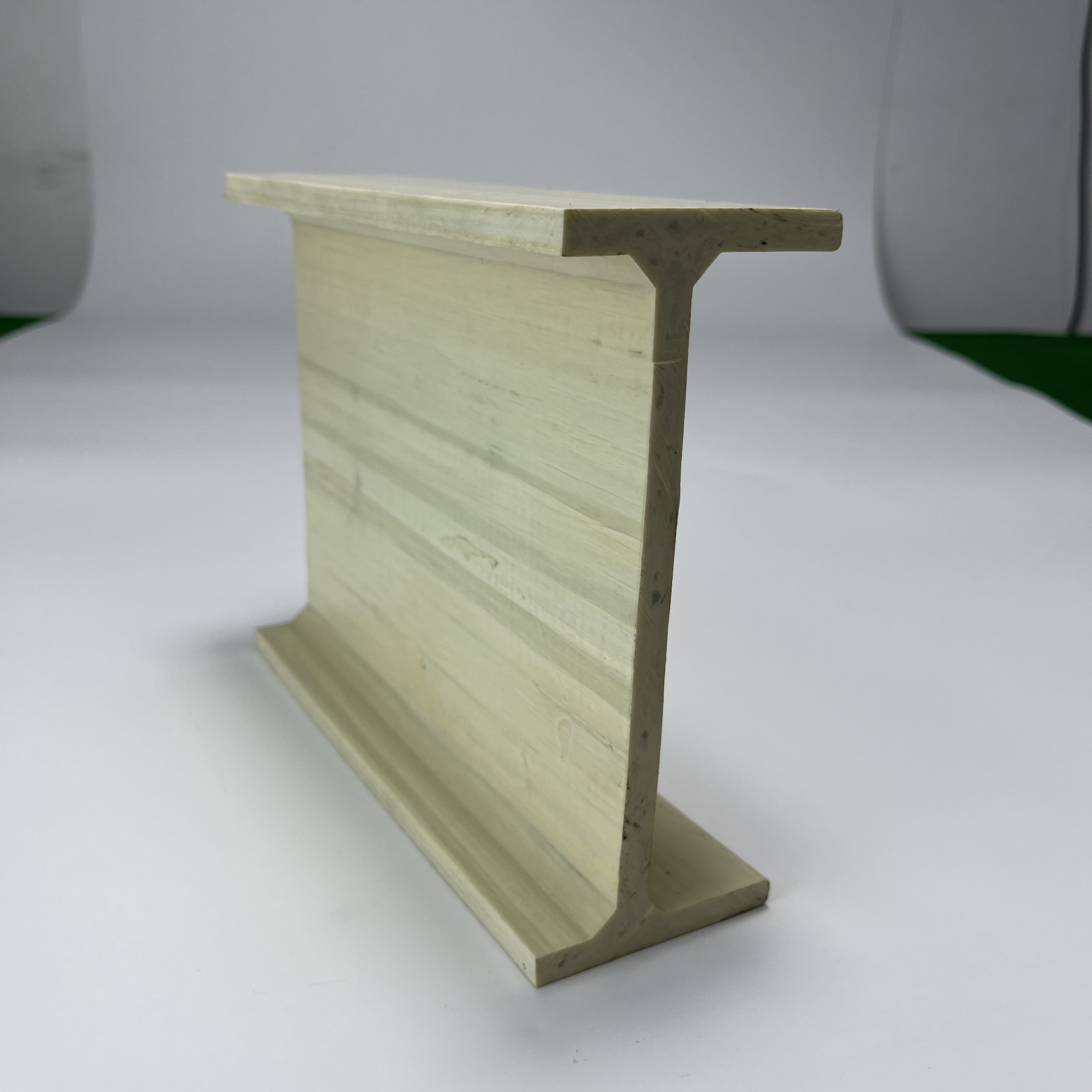

Product Name

|

FRP I beam

|

|

|

|

Material

|

Fiberglass, Resin, Felt

|

|

|

|

Color

|

Any color

|

|

|

|

MOQ

|

500 meters

|

|

|

|

Size

|

Customized

|

|

|

|

Process

|

Pultrusion Technology

|

|

|

|

Surface

|

Smooth

|

|

|

|

Usage

|

The framework material, support structural

|

|

|

FAQ

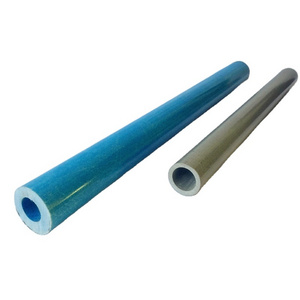

* Q: What’s FRP?

A: Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibres are

usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper or wood or asbestos have been used. The polymer is

usually an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are still in use. FRPs are

commonly used in the aerospace, automotive, marine, construction industries and ballistic armor.

* Q: How can you guarantee your product quality?

A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high

quality supplier.

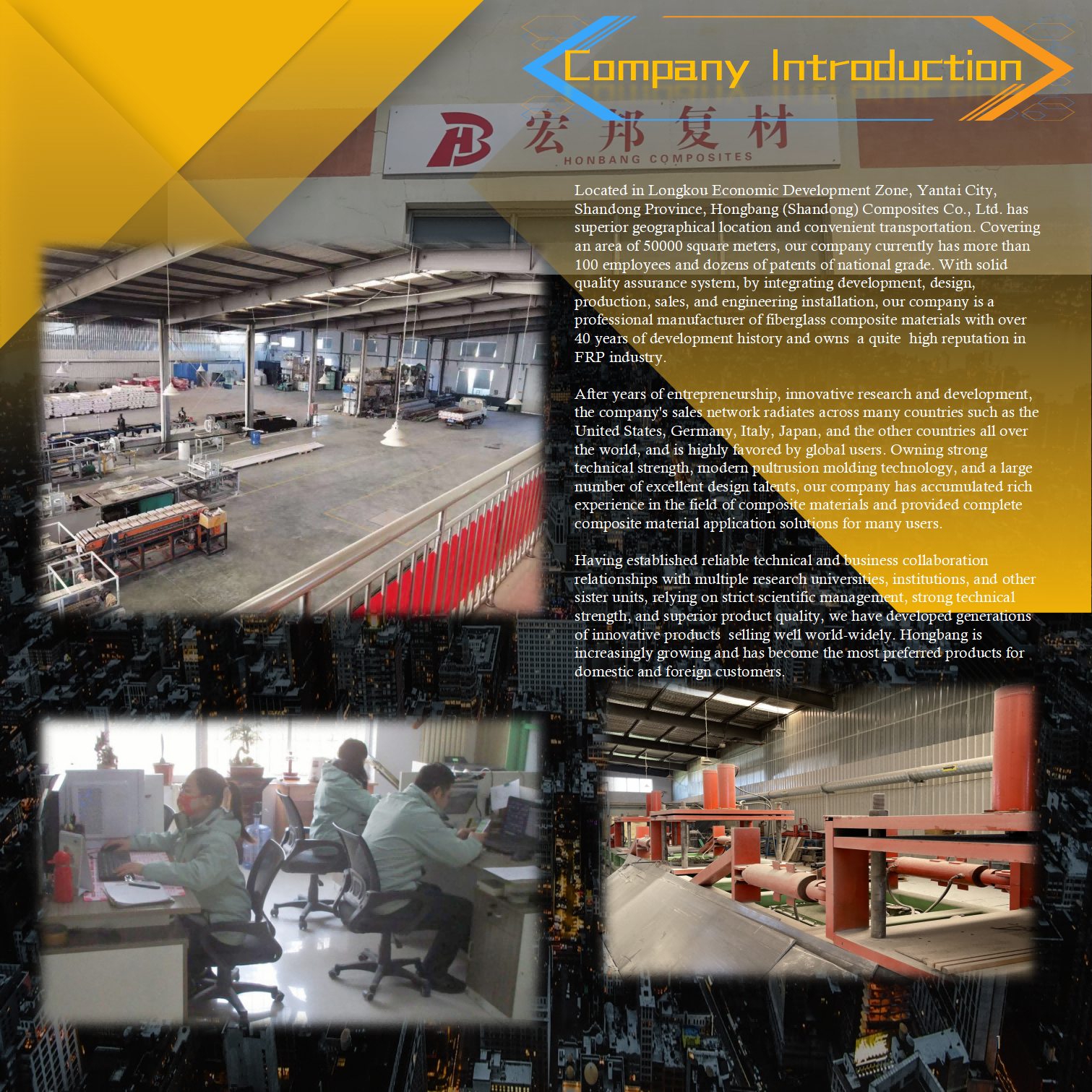

* Q: Are you a trading company or a manufacturing factory?

A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China

since 1979.

* Q: I am interested in your products, could I get sample for free?

A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping

account.

* Can you do the design for us?

A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customized shape,dimension,

colors service.

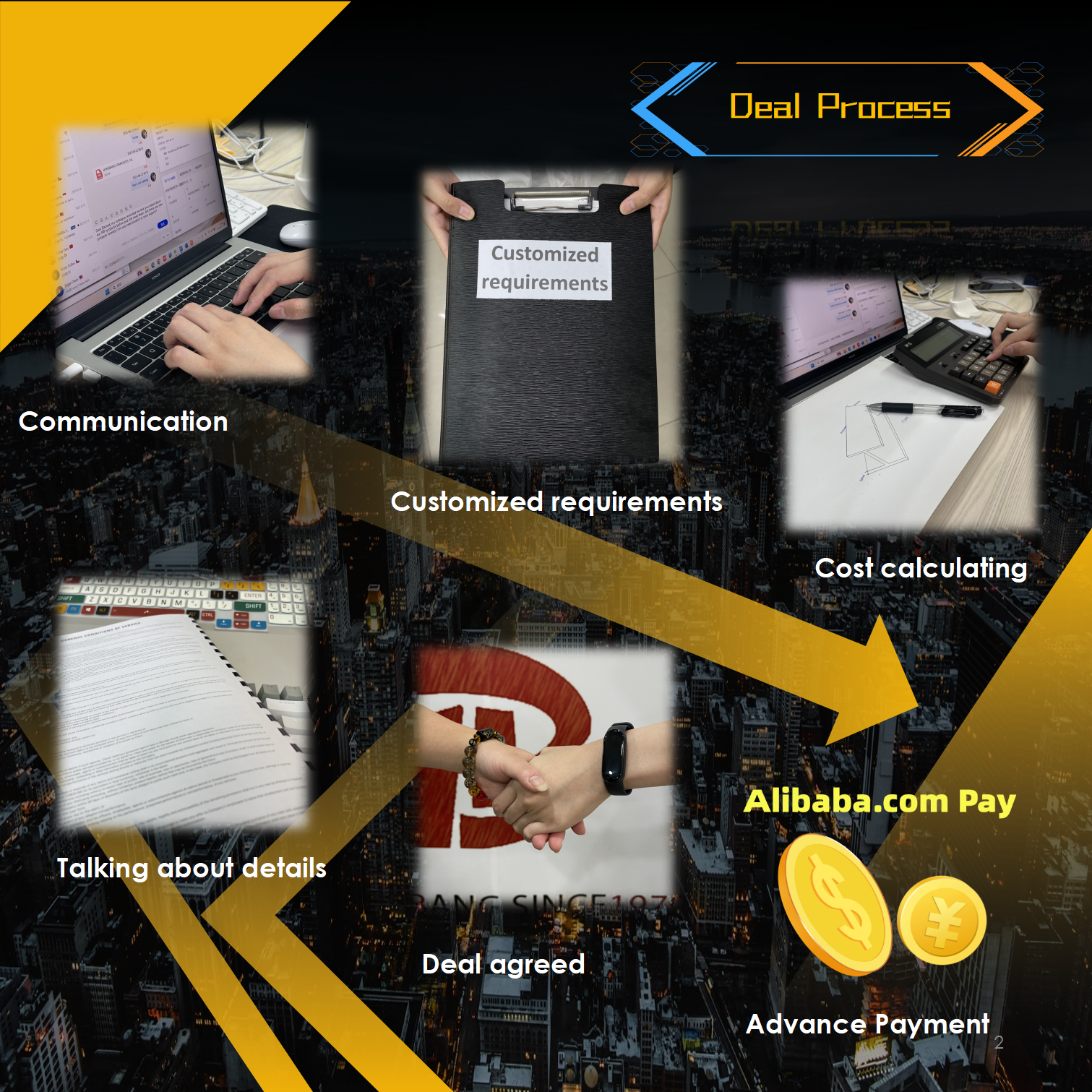

* What are the steps to cooperate for specific customized products?

1.) we confirm CAD drawing according to buyer's requirement.

2.) Confirm purchasing invoice after discussing by two joint parties.

3.) Start mold munufacturing after 30% TT in adv. (100%TT for mold munfacturing cost)

4.) Sample is sent to test.

5.) Whole order production starts upon receiving sample confirmation from buyer.

6.) Products are sent out after balance payment.

A: Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibres are

usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper or wood or asbestos have been used. The polymer is

usually an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are still in use. FRPs are

commonly used in the aerospace, automotive, marine, construction industries and ballistic armor.

* Q: How can you guarantee your product quality?

A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high

quality supplier.

* Q: Are you a trading company or a manufacturing factory?

A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China

since 1979.

* Q: I am interested in your products, could I get sample for free?

A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping

account.

* Can you do the design for us?

A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customized shape,dimension,

colors service.

* What are the steps to cooperate for specific customized products?

1.) we confirm CAD drawing according to buyer's requirement.

2.) Confirm purchasing invoice after discussing by two joint parties.

3.) Start mold munufacturing after 30% TT in adv. (100%TT for mold munfacturing cost)

4.) Sample is sent to test.

5.) Whole order production starts upon receiving sample confirmation from buyer.

6.) Products are sent out after balance payment.

Hot Searches