1.Standard Boring Bar (customized)

40*1500 mm (1.57*59 Inches)

2.Boring Diameter

45-200 mm (1.77-7.87 Inches)

3.Stroke

390 mm (15.35 Inches)

4.Feed Speed

0-100(mm/min)

5.Power Option

1.5kw electric motor

220V single phase or 380V three-phase power

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

45 mm

-

Travel (W-axis) (mm):

-

100 mm

-

Marketing Type:

-

Hot Product 2022

-

Positioning Accuracy (X axis) mm:

-

0.1

-

Positioning Accuracy (Y axis) mm:

-

0.1

-

Positioning Accuracy (Z axis) mm:

-

0.1

-

Range of Spindle Speed(r.p.m):

-

200 r.p.m

-

Spindle Motor Power(kW):

-

1.5

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MMP

-

Voltage:

-

220V/380V/CUSTOMIZED

-

Weight (T):

-

95 T

-

Model:

-

MMP-40T

-

Name:

-

Portable Line Boring Machine

-

Brand:

-

MMP

-

Power unit:

-

1.5KW

-

Boring Diameter:

-

45-200 mm (1.77-7.87 Inches)

-

Boring Stroke:

-

390mm

-

Rotating speed:

-

0-140rpm variable speed

-

Feed Speed:

-

0-100(mm/min)

-

Application:

-

Construction Machine Repairing

Quick Details

-

Table Size (mm):

-

40*1500 mm (1.57*59 Inches)

-

Table Travel (X) (mm):

-

200 mm

-

Table Travel (Y) (mm):

-

200 mm

-

Table Travel (Z) (mm):

-

45 mm

-

Travel (W-axis) (mm):

-

100 mm

-

Marketing Type:

-

Hot Product 2022

-

Positioning Accuracy (X axis) mm:

-

0.1

-

Positioning Accuracy (Y axis) mm:

-

0.1

-

Positioning Accuracy (Z axis) mm:

-

0.1

-

Range of Spindle Speed(r.p.m):

-

200 r.p.m

-

Spindle Motor Power(kW):

-

1.5

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MMP

-

Voltage:

-

220V/380V/CUSTOMIZED

-

Weight (T):

-

95 T

-

Model:

-

MMP-40T

-

Name:

-

Portable Line Boring Machine

-

Brand:

-

MMP

-

Power unit:

-

1.5KW

-

Boring Diameter:

-

45-200 mm (1.77-7.87 Inches)

-

Boring Stroke:

-

390mm

-

Rotating speed:

-

0-140rpm variable speed

-

Feed Speed:

-

0-100(mm/min)

-

Application:

-

Construction Machine Repairing

PRODUCTS DESCRIPTION

Why TO Choose The MITNIK MACHINE PARTS-MMP

MMP Portable Line Boring Machine for Excavator&Bulldozer Repair:

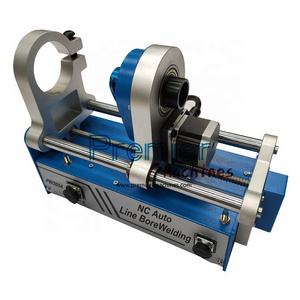

MMP-40T

Portable Line Boring Specification

MMP Portable Line Boring Machine

Performances:

1.Portable & Light-Weight

Aluminum alloy shell machine body, weight only 13Kg.

2.Easy And Flexible Setup

The boring bar goes through the machine body to ensure the coaxial of the main body and the boring bar. The machine body can be installed at any position of the boring bar and can be installed in a narrow space.

3.Durable And Reliable Performance

The patented feed mechanism is a reliable and durable structure with almost no fault.Infinite variable speed feed mechanism can achieve forward feed, reverse feed, and manual feed function.

4.Powerful And Optional Power

Powerful AC 2.2Kw drive motor, variable speed control by frequency converter. General motor, stable, easy maintenance. The connection between the motor and the machine body is convenient to disassemble, and the suitable motor can be replaced according to the local conditions. Optional power supply: 220V single phase or 380V three-phase power.

5.Customizable Portable Line Boring Machine

Bearing mount assembly can be designed according to needs. Adjustable mechanism ensures the coaxality of boring bar, main body and bearing mount assembly.

6.High-Tech Design

Advanced worm gear reducer, high efficiency and high torque output, cutting ability 8mm in the radius.

7.Precise Performance

The slotless structure avoids the bending deformation of the boring bar due to the machining stress.

8.Humanized Design

Feed stroke can be easily changed.

Easy to operate with the remote handle. The electric control box is separated from the mainbody, avoiding the loosening of

electric lines caused by the vibration the machining process.

1.Portable & Light-Weight

Aluminum alloy shell machine body, weight only 13Kg.

2.Easy And Flexible Setup

The boring bar goes through the machine body to ensure the coaxial of the main body and the boring bar. The machine body can be installed at any position of the boring bar and can be installed in a narrow space.

3.Durable And Reliable Performance

The patented feed mechanism is a reliable and durable structure with almost no fault.Infinite variable speed feed mechanism can achieve forward feed, reverse feed, and manual feed function.

4.Powerful And Optional Power

Powerful AC 2.2Kw drive motor, variable speed control by frequency converter. General motor, stable, easy maintenance. The connection between the motor and the machine body is convenient to disassemble, and the suitable motor can be replaced according to the local conditions. Optional power supply: 220V single phase or 380V three-phase power.

5.Customizable Portable Line Boring Machine

Bearing mount assembly can be designed according to needs. Adjustable mechanism ensures the coaxality of boring bar, main body and bearing mount assembly.

6.High-Tech Design

Advanced worm gear reducer, high efficiency and high torque output, cutting ability 8mm in the radius.

7.Precise Performance

The slotless structure avoids the bending deformation of the boring bar due to the machining stress.

8.Humanized Design

Feed stroke can be easily changed.

Easy to operate with the remote handle. The electric control box is separated from the mainbody, avoiding the loosening of

electric lines caused by the vibration the machining process.

PRODUCT SPECIFICATIONS

|

MITNIK/MMP-Portable Line Boring Machine

|

|

|

|

|

||||

|

Model

|

Boring Diameter

|

Standard Boring Bar

(Customizable)

|

Feed Speed

|

Power Optional

|

||||

|

MMP-50B

|

55-350 mm (2.17-13.78 Inches)

|

50*1500 mm (1.97*59 Inches)

|

0-0.5mm/r

|

2.2Kw electric motor

|

||||

|

MMP-60B

|

100-500 mm (3.93-19.69 Inches)

|

60*2000 mm (2.36*78.74 Inches)

|

|

2.2 Kw electric motor

220V single phase or 380V three-phase power |

||||

|

MMP-60YK

|

65-400 mm (2.56-15.75 Inches)

|

60*1500 mm (2.36*59 Inches)

|

|

1.8Kw Germany electric motor

|

||||

|

MMP-40T

|

45-200 mm (1.77-7.87 Inches)

|

40*1500 mm (1.57*59 Inches)

|

0-100(mm/min)

|

1.5kw electric motor

|

||||

|

MMP-50T

|

55-250 mm (2.17-9.84 Inches)

|

50*1500 mm (1.97*59 Inches)

|

0-100(mm/min)

|

1.5kw electric motor

|

||||

|

MMP-60T

|

60mm boring bar: 63.5-609.6 mm (2.5″ to 24″)

30mm & 60mm boring bar: 38.1 to 609.6mm (1.5″ to 24″) |

60*2000 mm (2.36*78.74 Inches)

30mm and 35mm boring bar optional |

Variable Tool Feed Rate

0 to 0.024″/r (0-0.6mm/r) |

Electric motor 2.2 KW 3.0HP

Servo motor 2.5 KW 3.3 Hp Hydraulic motor 15 KW 20.4 Hp |

||||

|

MMP-90T

|

95-900 mm (3.74-35.43 Inches)

|

90*2000 mm (3.54*78.74 Inches)

|

0-0.6mm/r

|

Hydraulic/Servo motor 3KW

|

||||

|

MMP110T

|

180-1000 mm (7.09-39.37 Inches)

|

110*2500 mm (4.33*98.43 Inches)

|

180-1000 mm (7.09-39.37 Inches)

|

Hydraulic/Servo motor 3KW

|

||||

|

MITNIK/MMP-Portable Line Boring Machine

with Welding Machine

|

|

|

|

|

||||

|

Model

|

Inner Welding and

Welding torch length

|

Stroke

|

Feed Speed

|

Power Option

|

||||

|

MMP-40TW

|

Inner Welding 50-300 mm (1.97-11.8 Inches)

Welding torch length 1200 mm (47.2 Inches)-customizable |

390 mm (15.35 Inches)-customizable

|

0-100(mm/min)

|

1.5kw electric motor

|

||||

|

MMP-50TW

|

Inner Welding

50-300 mm (1.97-11.8 Inches) Welding torch length 1200 mm (47.2 Inches)-customizable |

390 mm (15.35 Inches)-customizable

|

0-100(mm/min)

|

1.5kw electric motor

|

||||

Please verify part number prior to order.

Thanks for viewing our listings. Please click "Ask A Question", or call us if you have a parts need that you do not see listed here.

We will do our best to locate the parts you need, and make every effort to save you money.

For parts information in English please CONTACT US

For parts information in English please CONTACT US

MITNIK PARTS PACKING

RECOMMEND PRODUCTS

MITNIK COMPANY PROFILE

MITNIK MACHINE PARTS(MMP BRAND)

is the worldwide leader in replacement parts and original parts and accessories for Engineering Machine, Construction Machine, Industrial Truck and Agricultural Equipment over 20 years old.

MITNIK MACHINE PARTS have set up a one-stop shopping platform for engineering construction machinery parts, and the products:involve: excavator&bulldozer undercarriage (track roller, carrier roller, track link, track idler, track link assy, track shoe, segment group, sprocket, bushing, pin, bolt&nut), engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit), engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..), hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine), dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

With more than 20 years experience on heavy duty machinery spare parts sales, our important customers are mainly distributed in South- East Asia, Mid-East, South America and some East European countries.

MITNIK MACHINE PARTS have set up a one-stop shopping platform for engineering construction machinery parts, and the products:involve: excavator&bulldozer undercarriage (track roller, carrier roller, track link, track idler, track link assy, track shoe, segment group, sprocket, bushing, pin, bolt&nut), engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit), engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..), hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine), dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

With more than 20 years experience on heavy duty machinery spare parts sales, our important customers are mainly distributed in South- East Asia, Mid-East, South America and some East European countries.

MITNIK COMPANY ADVANTAGES

SALES AND SERVICE NETWORK

Project in Europe

Project in

Australia

Project in Brazil

FAQ

1. You are a trader or a manufacture?

MITNIK MACHINE PARTS with one-stop shopping platform for engineering construction machinery parts as MITNIK have our own factory and storage warehouse and some parts of them were supply by our Joint Stock Partnership to ensure to provide excellent products and service to our customers, at competitive prices.

We are manufactuer and trade integration business, our factory located on Quanzhou Nanan Distric, and our sales department is in City centre of Xiamen.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or Trade Assurance. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB Xiamen or any Chinese port : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

Hot Searches