- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

as required

-

Power:

-

as required

-

Dimension(L*W*H):

-

non-standard

-

Weight (KG):

-

5000

-

Application:

-

casting plant, metallurgy, steel structure, shipbuilding

-

Capacity:

-

5t/h - 60t/h

-

Warranty Service:

-

1year

-

Raw material:

-

steel and iron

-

Color:

-

mainly green or blue or custormers' requirement

-

Usage:

-

sand molding for pouring molten iron

-

Machine Material:

-

steel and iron

-

After-sales Service Provided:

-

life long service

-

delivery:

-

from our factory

-

Plc:

-

international brands

Quick Details

-

Place of Origin:

-

Henan, China

-

Machine Type:

-

non-standard line

-

Brand Name:

-

HC

-

Voltage:

-

as required

-

Power:

-

as required

-

Dimension(L*W*H):

-

non-standard

-

Weight (KG):

-

5000

-

Application:

-

casting plant, metallurgy, steel structure, shipbuilding

-

Capacity:

-

5t/h - 60t/h

-

Warranty Service:

-

1year

-

Raw material:

-

steel and iron

-

Color:

-

mainly green or blue or custormers' requirement

-

Usage:

-

sand molding for pouring molten iron

-

Machine Material:

-

steel and iron

-

After-sales Service Provided:

-

life long service

-

delivery:

-

from our factory

-

Plc:

-

international brands

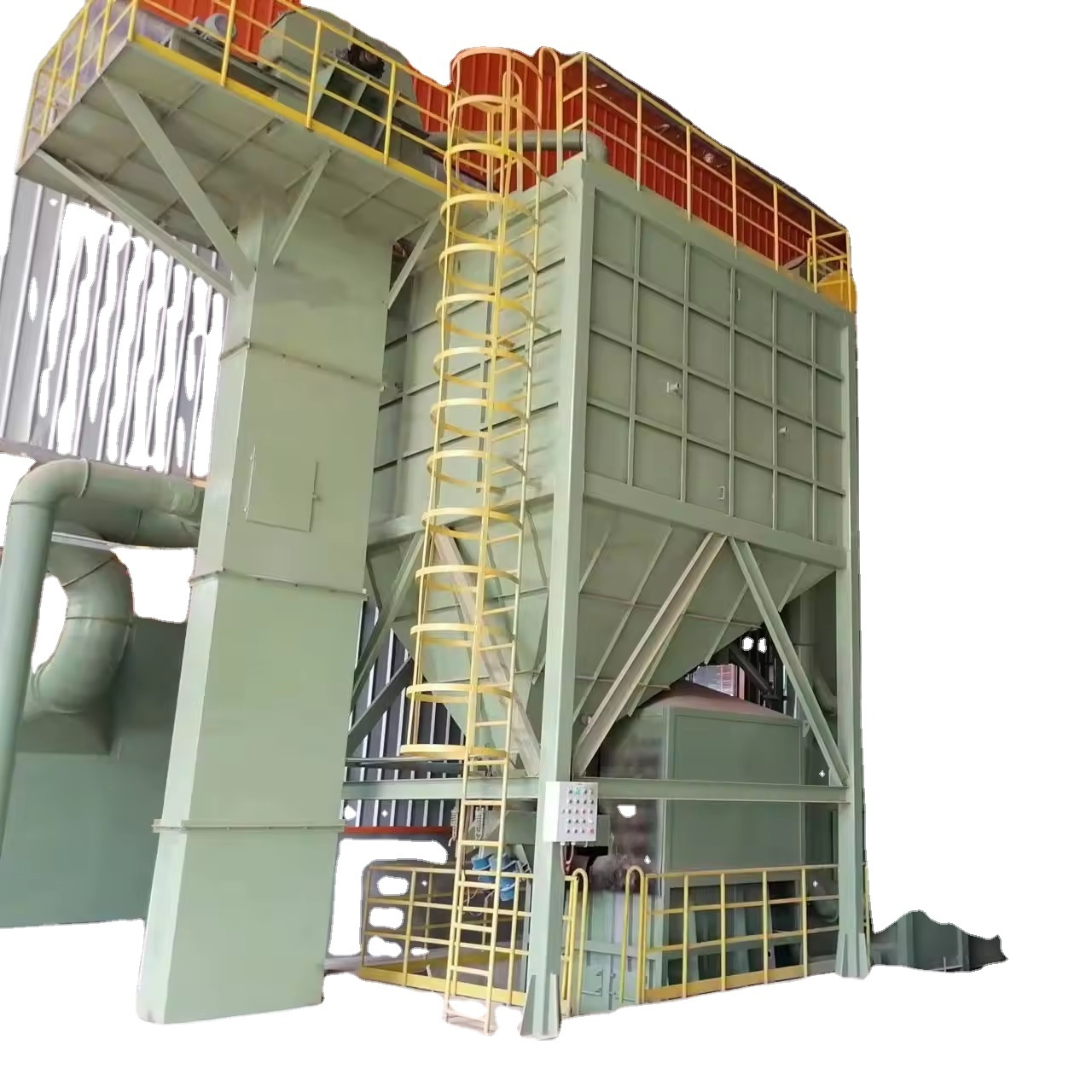

Products Description

Lost foam casting, known as solid casting, is also known as "green revolution in manufacturing industry."

First coat the foam models of the same sizes with castings with fireproof paint and then dry them. Bury them into dry quartz sand or pearl sand or magnesium olivine sand and then vibrate together to mold. Pour metal iron&steel under negative pressure, the foam model lost and vaporized, and the liquid metal occupies the position of the model and solidifies and cools to form and get castings.

First coat the foam models of the same sizes with castings with fireproof paint and then dry them. Bury them into dry quartz sand or pearl sand or magnesium olivine sand and then vibrate together to mold. Pour metal iron&steel under negative pressure, the foam model lost and vaporized, and the liquid metal occupies the position of the model and solidifies and cools to form and get castings.

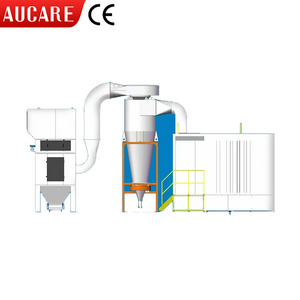

Introduction of lost foam flexible automatic line

This line has molding system, pouring system,

shakeout system and other systems, which are flexible connection, free rhythm, reliable operation, flexible work and do not disturb each other. All line’s PLC centralized control and its working condition is displayed on the analog screen, convenient and intuitive, high production efficiency, Suitable for mass automated production.

Hot Searches