- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50Hz

-

Current:

-

Max 500A

-

Rated Capacity:

-

Depends on welding requirement

-

Rated Duty Cycle:

-

Depends on welding requirement

-

Dimensions:

-

1900*1100*1800

-

Use:

-

seam welding

-

After-sales Service 1 Provided:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Other

-

Color:

-

Blue or Customized

-

Weldment:

-

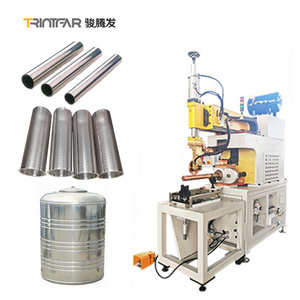

Tubes, flat sheets, cylinders, cones, sinks, tank shells etc.

-

Weldable Material:

-

Any weldable materials like Steel, Alloy, Aluminum etc.

-

Options:

-

Wire feeder, Oscillator, Tracker

-

Service:

-

OEM, ODM

-

Weight:

-

1150Kg

-

Certification:

-

CE/ISO9001

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Hanyan Technology

-

Weight (KG):

-

1150

-

Voltage:

-

220V 50Hz

-

Current:

-

Max 500A

-

Rated Capacity:

-

Depends on welding requirement

-

Rated Duty Cycle:

-

Depends on welding requirement

-

Dimensions:

-

1900*1100*1800

-

Use:

-

seam welding

-

After-sales Service 1 Provided:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Other

-

Color:

-

Blue or Customized

-

Weldment:

-

Tubes, flat sheets, cylinders, cones, sinks, tank shells etc.

-

Weldable Material:

-

Any weldable materials like Steel, Alloy, Aluminum etc.

-

Options:

-

Wire feeder, Oscillator, Tracker

-

Service:

-

OEM, ODM

-

Weight:

-

1150Kg

-

Certification:

-

CE/ISO9001

Chengdu Hanyan Technology Co., LTD. is a national high-tech enterprise specializing in designing, researching and developing, manufacturing and serving of automatic welding equipment.

With 360 employees, including 159 who have been devoting into welding area for over 15 years, we are serving customers worldwide with dozens of various types of precision equipment and a factory covering an area of 15000sqm. To establish modern management, we customized an ERP system which could ensure punctual delivery and offer process surveillance. We have accomplished more than 20 patents in automatic welding industry. We are capable of providing 4000 units specialized welding equipment annually.

Product Description

Designed for longitudinal seam welding.

Can be used with TIG/MIG/MAG/PAW and other welding powers and torches for different welding needs.

|

Model |

Welding length(mm) |

Welding thickness(mm) |

Applicable diameter(mm) |

Dimension(mm) |

Weight (Kg) |

||

|

Length |

Width |

Height |

|||||

|

ZF-500 |

500 |

0.5-3.0 |

75-750 |

1320 |

1000 |

1800 |

390 |

|

ZF-1000 |

1000 |

0.5-6.0 |

115-700 |

1900 |

1100 |

1800 |

1150 |

|

ZF-1500 |

1500 |

0.5-6.0 |

150-700 |

2475 |

1100 |

1850 |

1550 |

|

ZF-2000 |

2000 |

0.5-6.0 |

180-700 |

2980 |

1100 |

1850 |

2050 |

|

ZF-2500 |

2500 |

0.5-6.0 |

200-700 |

3455 |

1100 |

1950 |

2450 |

|

ZF-3000 |

3000 |

0.5-6.0 |

270-700 |

4340 |

1100 |

1950 |

3050 |

Update to though out straight seam welder

The welding process

ZF Series

HANYAN ZF Series external seam welders are designed for external welds on cylinders and flat sheets

Standard

Precision

Extra-Precision

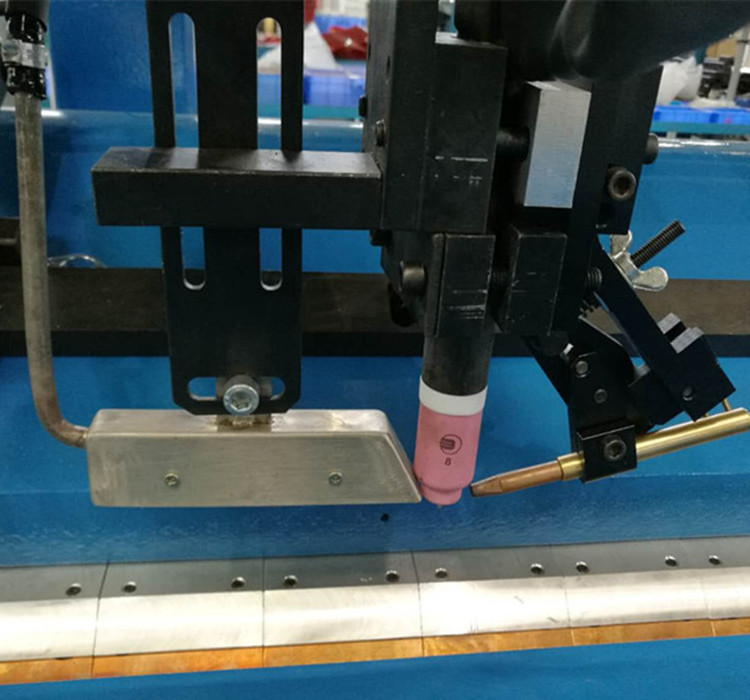

Copper tip clamping fingers

Copper tipped, aluminum hold down fingers are standard on all HANYAN seam Welders. The copper tipped hold down fingers assist in the chilling the weld joint. Copper tooling absorbs and dissipates heat through the use of additional thermal mass, operating under pressure against work piece.

Back-up insert

Inserts are quickly and easily interchanged into the backup mandrel to accommodate a variety of material types and thicknesses. Copper inserts dissipate heat generated during the welding process.

Additional inserts are available to cover a wide range of material types and thicknesses. Inserts are available with or without gas back-up capabilities.

Back-up Mandrel

Designed to support the part being welded and hold the back-up inserts.

Droop mandrels are available to ease loading and unloading of parts.

Optional water cooled mandrels are available.

Fixed and removable riser options

Seam welder base can be modified to accommodate larger diameter parts.

Chengdu Hanyan Technology Co., Ltd.

is a national high-tech enterprise who specializing in designing, researching and developing, manufacturing and serving of automatic welding equipment. wholly-owned three sub-companies, covering resistance welding, robot welding and welding power source.

From now on, we obtained 5 Patents of invention and 13 Patents of Utility Model; our products are approved by CCC and CE, additionally, our company have had ISO 9001:2008, ERR and CRM management system.

We exported to over 29 countries and regions including General Longitudinal/Circumferential Seam Welder, Welding Auxiliaries, Water Heater Welding Line, Fuel Tank Welding Line, Welding Robots, Strip Welding Equipment, Resistance Welding Equipment, Welding Power Sources and other Customized Welding Equipment.