- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11KW*2

-

Dimension(L*W*H):

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Name:

-

shot blasting machine

-

color:

-

according to your requirement

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BESTECH

-

Weight (KG):

-

12500 KG

-

Power:

-

11KW*2

-

Dimension(L*W*H):

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Name:

-

shot blasting machine

-

color:

-

according to your requirement

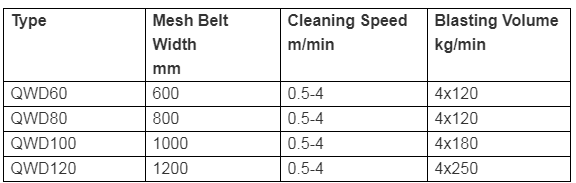

Wire mesh belt shot blasting machine

Wire mesh belt shot blasting machine is mainly used for automobile,aerospace railway and other machine manufacturing industry,especially suitable for the surface shot blasting of the thin-walled iron castings or aluminium castings and other small parts.It can be used for mechanical parts shot blasting strengthen.

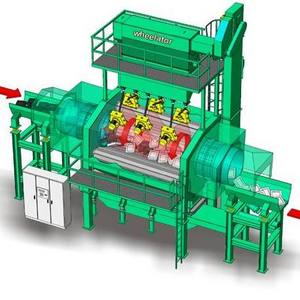

Wire Mesh Belt Shot Blasting Machine will have mesh Conveyor System, Blowing Sand System, Vertical Screw Conveyer, Blasting Chamber, Blast Wheel, Bucket Elevator,Screw Conveyer, Separator, Maintenance Platform & Ladder, Providing Sand System, and soon on.

Main component:

Containment — The physical structure of the room itself, a containment system is designed to remain sealed to prevent blasting material from escaping the room.

• Blasting System — Blasting systems come in different forms and are capable of using various blasting media. Wheel blasting is the standard blasting method in all blast rooms;

• Dust Collection — Dust collection systems involve the flow of air through filters in the room, which remove dust from the blasting operation.

• Material Recycling — Most rooms have a means of recycling used blasting media.

Application:

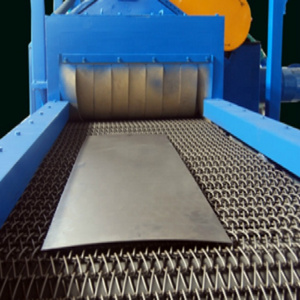

Wire mesh belt shot blasting machine/shot blasting equipment is mainly used for automatic, aerospace railway and other machine manufacturing industry, especially suitable for the surface of the thin-walled iron castings,aluminium castings,fragile iron, ceramics and other small parts.

Product feature:

1.Good continuity

2. High cleaning efficiency

3. Small deformation

4. No pit needed.

5.Wire mesh belt structure

6.Fully automatic operation

Design and Sequence of Operations

-

Parts placed on the wire mesh belt conveyor continuously pass through abrasive tight entry vestibule into the blast chamber.

-

The quantity and placement of the blast wheels coupled with the blast wheel horsepower determine the cleaning capacity and production capabilities of the machine. Blast wheels ensure complete coverage and cleaning of every angle.

-

The parts are blast cleaned passing through the blast chamber and then exit through the series of seals in the egress vestibule.

Machine details:

-

We offers a complete line of stationary, airless centrifugal blast cleaning machinery that clean items at a fraction of the cost of conventional air-blast cleaning methods.

-

Our direct drive blast wheels offer consistent production and superior performance.

-

The abrasive media is cleaned and recycled, reducing disposal and minimizing abrasive costs.

-

Several product groups are available, as well as specially engineered products to meet individual requirements.

-

The number and power of the turbines are chosen according to the requirement production rate.

-

Optional PLC control system, stable quality and easy to get support from local.

-

Component key parts adopt world famous brand, such as Siemens, Omron, Schneider, Mitsubishi.

-

No-pit, easy for install and move and save cost.

-

Compacted structure and scientific design. Can be designed and manufactured according to the order.

-

Widely used in cleaning and strengthening for Fragile parts.

-

20 years experienced engineers, customized service avaliable.

-

After-sale service support will be provided within 24hours.