- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Blue or Client's Request

-

Inner Diameter:

-

450-550mm

-

Out Diameter:

-

1550mm

-

Power:

-

4kw

-

Hydraulic Power:

-

3kw

-

Max Coil Weight:

-

5 Ton / 7 Ton / 8 Ton / 10 Ton

-

Max Coil Width:

-

1250 mm

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

1000

-

Product name:

-

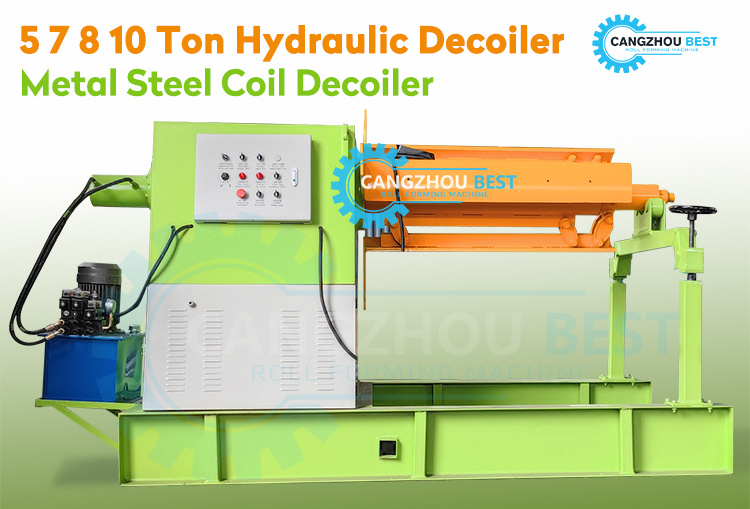

5 7 8 10 Ton Hydraulic Decoiler

-

Color:

-

Blue or Client's Request

-

Inner Diameter:

-

450-550mm

-

Out Diameter:

-

1550mm

-

Power:

-

4kw

-

Hydraulic Power:

-

3kw

-

Max Coil Weight:

-

5 Ton / 7 Ton / 8 Ton / 10 Ton

-

Max Coil Width:

-

1250 mm

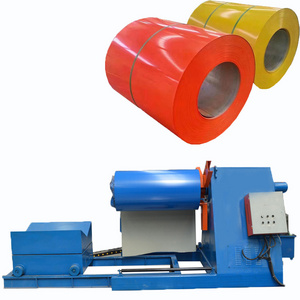

Factory Supplied Automatic Metal Coil Hydraulic Decoiler Machine 5T 7T 8T 10T Steel Coil Uncoiler Machine

5T 7T 8T 10T Hydraulic Decoiler:

-

5Ton 7Ton 8Ton 10Ton Hydraulic Decoiler Introduction

The hydraulic decoiler is use for match with roof sheet machine, floor deck machine, cutting to length machine, slitting machine and other kind of machine that dispose the metal coil, make it uncoiling. Coil weight can max reach to 10 Tons, max width reach to 1250 mm. Loading car can move up and down, going forward and backward to help loading the coil easily.

| Product name | 5 Ton / 7 Ton / 8 Ton / 10 Ton Hydraulic Decoiler | Color | Blue or Client's Request |

| Inner diameter | 450-550mm | Out diameter | 1550mm |

| power | 4kw | Hydraulic power | 3kw |

| Usage | metal uncoiling | Suitable to process | Steel |

| Max Coil Weight | 5 Ton / 7 Ton / 8 Ton / 10 Ton | Max coil width | 1250 mm |

-

Hydraulic Decoiler Equipment Advatage

The hydraulic decoiler is used to support the coil . Compared with the manual decoiler, it is more convenient .

It can load the coil automatically. And it can make the coil go foreward and reversal.

-

5/7/8/10 Ton Hydraulic Decoiler The Introduction

This auto uncoiler is used to support the coil for roll forming machine

1. Automatic uncoiler is an auxiliary equipment for roll forming machine.It is composed of feed main machine, hydraulic station and control system. When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

3. The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

Main Workflow Of Roll Forming Machine :

Uncoiler ----- Molding core ----- Hydraulic System ----- Automatic Control system ----- Step Formed Mechanism -----Automatic Shearing Mechanism ----- Products Receiving Tables

Roll Forming Machine Components:

|

No. |

Name |

Qty |

|

1 |

De-coiler |

1 Set |

|

2 |

Feeding Device With Pre-sliding Cutter |

1 Set |

|

3 |

Roll Forming Machine |

1 Set |

|

4 |

Cut-off Device |

1 Set |

|

5 |

PLC Control Box |

1 Set |

|

6 |

Hydraulic Pump Station |

1 Set |

|

6 |

Production Support Table |

1 Set |

| Factory Supplied Automatic Metal Coil Hydraulic Decoiler Machine 5T 7T 8T 10T Steel Coil Uncoiler Machine | |

|

Material thickness |

0.3-0.8mm |

|

Diameter of shaft(solid shaft) |

70mm |

|

Material of shaft (solid shaft) |

(high grade) 45# Steel, quenching and tempering treatment |

|

Material of roller |

45# steel polished and coated with chrome HRC55-60° |

|

Reducer |

8# cycloid reducer (high grade) |

|

Cutting |

hydraulic cutting after roll forming |

|

Control system |

PLC Frequency Control System with touch screen |

Glazed Tile Type Roll Forming Sheet :

Corrugated Type Roll Forming Sheet :

IBR Type Roll Forming Sheet :

My workshop and loading for customer

1:How to play order: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the doposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

If any questions,you can call me mobile phone at any times

3:If you want to get more pictures or videos of the machines,I can send them to you by Email or SKype.

we are capable of designing machine totally as your panel sample and profile drawing

please no hesitate to contact us.

warmly welcome to visit our factory and order machine, we promise to provide you machine with best quality !