- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

Other, 400*200*200 mm, 600*200*200mm, 600*100*200mm, 600*250*200mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V-415V

-

Dimension(L*W*H):

-

4.2*1.2*0.6M

-

Weight (KG):

-

500000 kg

-

techincal:

-

Germany YTONG

-

Type::

-

Sand AAC & Flyash AAC

-

Capacity:

-

30,000-300,000m3

-

Cutting machine:

-

4.2-4.8-6m

-

mold weight:

-

2.8T

-

mold steel plate thickness:

-

10mm

-

side plate thickness:

-

12mm

-

working area:

-

10000m2-20000m2

-

working shift:

-

2 shifts

-

workers:

-

12-24 workers

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, AAC Block Making Machine

-

Brick Raw Material:

-

sand

-

Production Capacity (Pieces/8 hours):

-

50000~300000M3/Year

-

Brick size:

-

Other, 400*200*200 mm, 600*200*200mm, 600*100*200mm, 600*250*200mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220V-415V

-

Dimension(L*W*H):

-

4.2*1.2*0.6M

-

Weight (KG):

-

500000 kg

-

techincal:

-

Germany YTONG

-

Type::

-

Sand AAC & Flyash AAC

-

Capacity:

-

30,000-300,000m3

-

Cutting machine:

-

4.2-4.8-6m

-

mold weight:

-

2.8T

-

mold steel plate thickness:

-

10mm

-

side plate thickness:

-

12mm

-

working area:

-

10000m2-20000m2

-

working shift:

-

2 shifts

-

workers:

-

12-24 workers

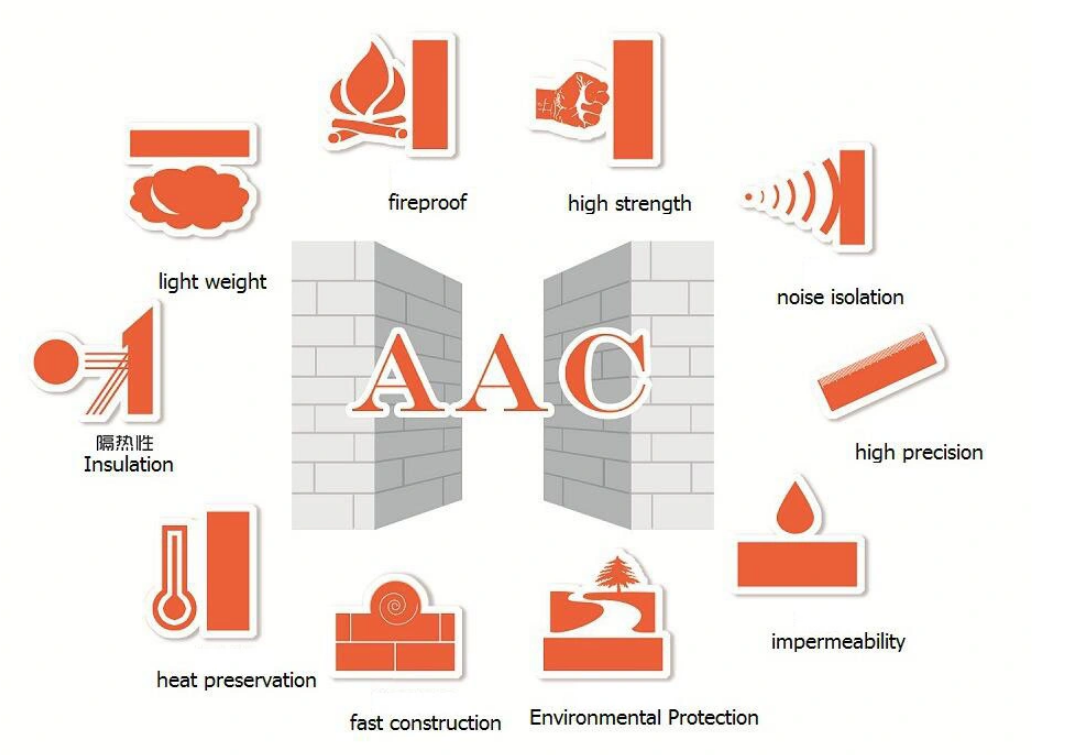

Product Description

AAC (Autoclave aerated concrete) block Main raw materials of AAC are siliceous material (sand, fly ash and Silicon) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting, autoclave and steaming etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclave aerated concrete.. It's a new type building materials of light,environmental,energy saving and so on. They could be used industry building and common building.Now,it is welcomed by more and more countries.

Advantages

Production process

AAC Gas Block Plant Running Process

1.

AAC block raw material process and storage

To make a the rational design of the raw materials process treatment and storage areas.

2. Batching&Weighing and Pouring

Batching and Weighing the dry powder material and sand slurry ,then

by the corresponding automatic metering metering, Batching and Weighing the dry powder material and sand slurry ,then by the corresponding automatic metering,high-speed mixing by inside of pouring mixer. after pouring into the mold box. The entire system PLC automated control to ensure material metering accurate and efficient operation.

by the corresponding automatic metering metering, Batching and Weighing the dry powder material and sand slurry ,then by the corresponding automatic metering,high-speed mixing by inside of pouring mixer. after pouring into the mold box. The entire system PLC automated control to ensure material metering accurate and efficient operation.

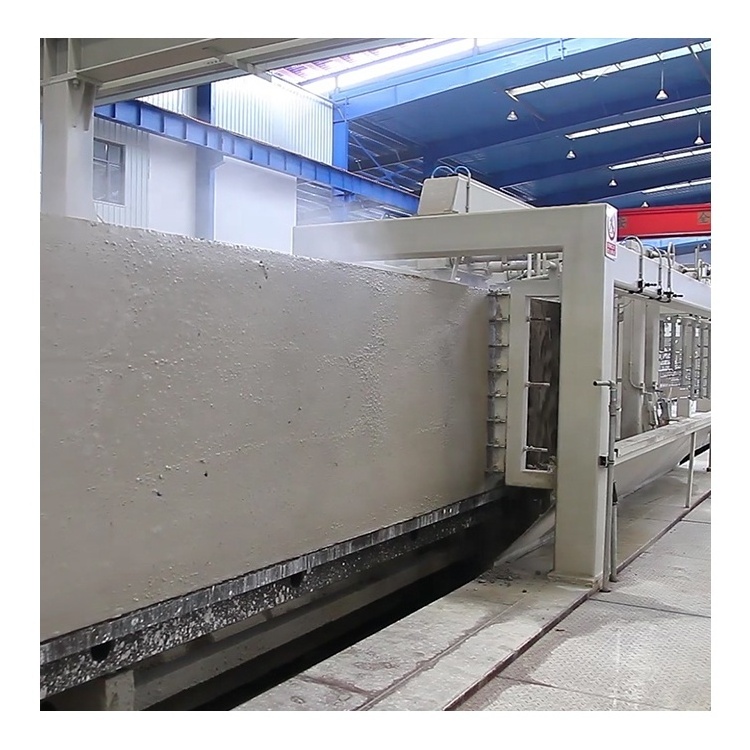

3. Curing hardening and cutting

Static stop curing in the curing room with temperature is 40-50degree. usually curing 3 hours for Sand slurry,the flyash curing time will be shorter about 1.5~2hours

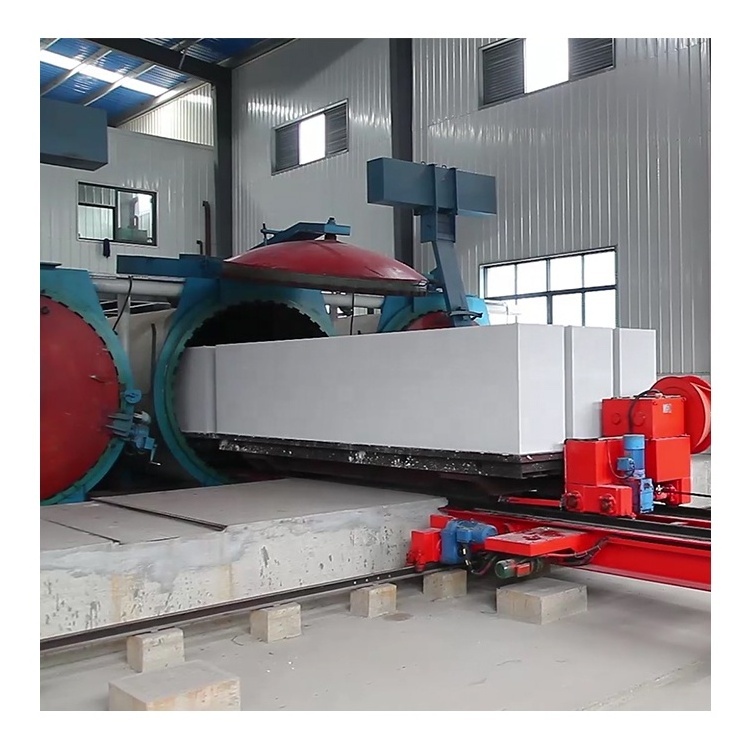

4. Aerated steaming and finished products package system

After autoclave steaming , AAC finished blocks obtain the finalstrength and performance.

the separator will running and make the sticky finished block separately, then go into the finished blocks packaging system.

AAC Block Introduction

Technical Paramenters

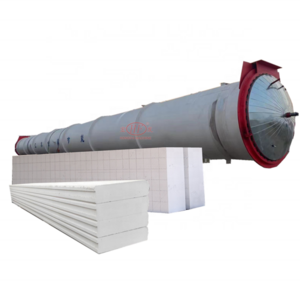

Ball Mill : Milling Lime into dry powder and sand into wet slurry

|

Type

|

Diameter mm

|

Length mm

|

Productivity

|

Feeeding size

|

Power(KW)

|

|

Φ1200x4500mm

|

1200

|

4500

|

3-4t/h

|

≤20mm

|

55

|

|

Φ1500x5700mm

|

1500

|

5700

|

6-8t/h

|

≤20mm

|

130

|

|

Φ1830x7000mm

|

1830

|

7000

|

8-17t/h

|

≤20mm

|

245

|

|

Φ2200x8000mm

|

2200

|

8000

|

18-20t/h

|

≤20mm

|

380

|

|

|

|

|

|

|

|

2. Slurry Pouring Mixer

To mix the sand ,slurry,lime,cement and aluminium paste into balance after measuring

|

Mixer type

|

Motor power

|

Mixer drum volume

|

Blade diameter

|

Blade speed

|

|

Diversion drum type

|

30kw

|

V=3.6m3

|

Φ560mm

|

560r/min

|

|

Diversion drum type

|

37kw

|

V=4.5m3

|

Φ630mm

|

560r/min

|

Mold Box

There are 4.2 M,4.8M ,6.0M there types sizes mold box can meet different capacity

|

Mold Inner Size (AAC block body net size)

|

Maximum overall size

|

|

|

||

|

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

||

|

4.2x1.2x0.6M

|

4720

|

1735

|

1078

|

||

|

4.8x1.2x0.6M

|

5320

|

1735

|

1078

|

||

|

6x1.2x0.6M

|

6550

|

1750

|

1085

|

||

Cutting Machine

Horizontal cutting machine

|

SIZE (Meter)

|

Min spacing of wires(mm)

|

Range of swing(mm)

|

Diameter of cutting wire(mm)

|

|

4.2X1.2X0.6

|

10mm

|

7.5

|

Diameter 0.6~1.0

|

|

4.8X.1.2X0.6

|

10mm

|

7.5

|

Diameter0.6~1.0

|

|

6.0x1.2x0.6

|

10mm

|

7.5

|

Diameter 0.6~1.0

|

Vertical Cutting Machine

Vertical cutting Machine technical parameter

|

SIZE (Meter)

|

Min spacing of wires (mm)

|

Diameter of cutting wires(mm)

|

|

|

|

|

|

diameter of wires(mm)

|

For side trimming(mm)

|

|

|

4.2x1.2x0.6

|

5

|

0.6~0.8

|

0.8

|

|

|

4.8X.12.X0.6

|

5

|

0.6~0.8

|

0.8

|

|

|

6.0X1.2X0.6

|

5

|

0.6~0.8

|

0.8

|

|

Flip Crane Hoist

overturning crane hoist transfer the cured AAC block body to cutting area

Finished AAC blocks Separator

Separating each sticky layers AAC blocks

Autoclave

Steaming cut AAC blocks to reach the required strength

Hot Searches