- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

3500 kg

-

Feeding width:

-

914-1450mm

-

Marketing Type:

-

Hot Product

-

Product name:

-

Cold Color Roof Wall Panel Plate Steel

-

Control system:

-

PLC(imported Brand)

-

Function:

-

Roof Panel Press Making

-

Color:

-

blue

-

Certification:

-

CE ISO

-

Operate style:

-

Hydraulic Oil Automatic Work

-

Suitable to process:

-

Galvanized Steel Plate

-

Decoiler:

-

3ton

-

Operation Language:

-

Customer's Real Request

-

Forming stations:

-

11-18 Rows

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-35m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

8.5*1.65*1.5m

-

Weight:

-

3500 kg

-

Feeding width:

-

914-1450mm

-

Marketing Type:

-

Hot Product

-

Product name:

-

Cold Color Roof Wall Panel Plate Steel

-

Control system:

-

PLC(imported Brand)

-

Function:

-

Roof Panel Press Making

-

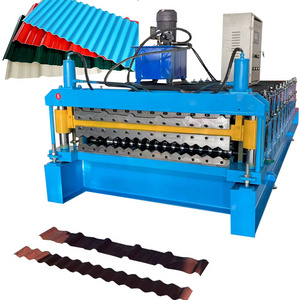

Color:

-

blue

-

Certification:

-

CE ISO

-

Operate style:

-

Hydraulic Oil Automatic Work

-

Suitable to process:

-

Galvanized Steel Plate

-

Decoiler:

-

3ton

-

Operation Language:

-

Customer's Real Request

-

Forming stations:

-

11-18 Rows

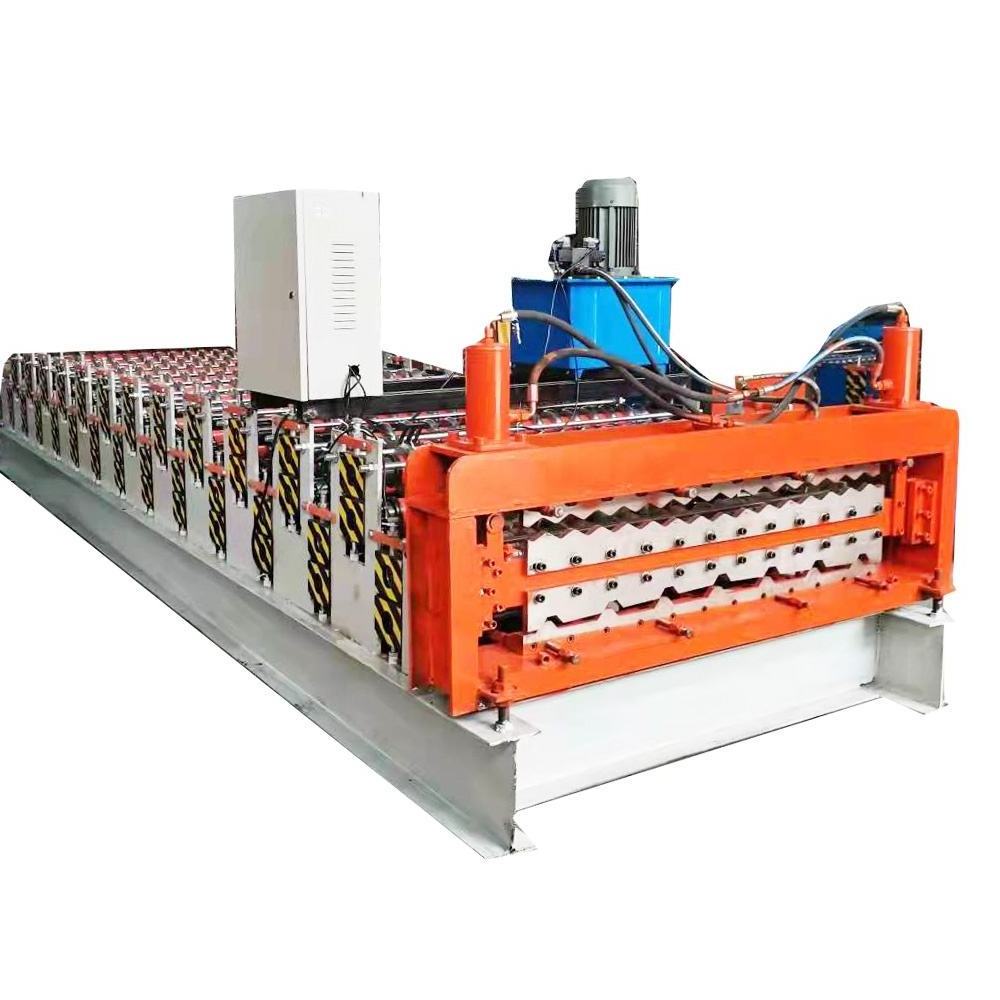

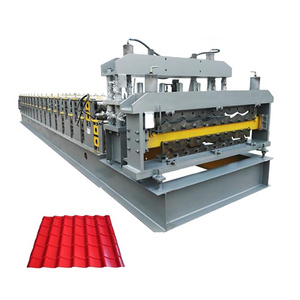

Products Description

Color Steel Roll Forming Machine

Color Steel Roll Forming Machine

suitable for industrial and civil buildings, warehouse special buildings, and large-span steel structure houses. Wall decoration, etc.

Product Paramenters

|

Model

|

HY-840/900

|

|

|

|

|||

|

Number Of Rows Of Molding

|

11 rows forming / 10 rows forming

|

|

|

|

|||

|

Rack Specifications

|

350H steel welding

|

|

|

|

|||

|

Motor Power

|

3kw

|

|

|

|

|||

|

Hydraulic Motor Power

|

3kw

|

|

|

|

|||

|

Dimension

|

3700x1100x1300mm

|

|

|

|

|||

|

Forming Speed

|

0—10m/min

|

|

|

|

|||

|

Cutter Material

|

Cr12 heat treatment

|

|

|

|

|||

|

Color

|

Customized

|

|

|

|

|||

DETAILS IMAGES

More stable wheels made by our lathe machine, which can save more cost.

The details pic of frame and all, when machine finished, all details will be share to you.

Powerful motor used by our machine, so that can make sure machine using more better, and design more beauty .

Whole machine is using the

chain drive, so that more powerful.

Other design for common using

Why Choose Us

All customized for our side is ok, just share with us.

1. Customized the roll former's language control box, in your own local language is ok.

2. Customized the design panel for you. As you prefer one. Once we finished machine, we will also recheck and compare it. In your side, if you still worries, you can also delivery your sample to our factory is ok. Welcome to do like that.

3. Customized the Color of roll former machine to you. Whatever color you prefer, just share with us is ok.

4. More better after-sale service will be provide, since make order until using, all the questions, you can check with us freely.

5. Alibaba payment also support, it will protect your rights all the time. And real our side also recommend that to you.

Shipping

Produce&Shipping of Tile making machine:

Product time of Tile Forming Machine:

25 working days. Cause machine need wheels making, frame making, and PLC, and voltage change, testing, which we all need time. If you real need machine hurrily, you can also consider the standard one of machine, it may just 7-9 days will be finished all.

Shipping Time of Tile Forming Machine:

2-5 days for domestic transport. If you need we make CIF price, pls share with us your nearest seaport .

Hot Searches