- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GDGW steel

-

Model Number:

-

band saw blade

-

Application:

-

saws blade, bandsaw blade

-

Processing Service:

-

heat treatment

-

Product Name:

-

c75s spring steel strip

-

Surface:

-

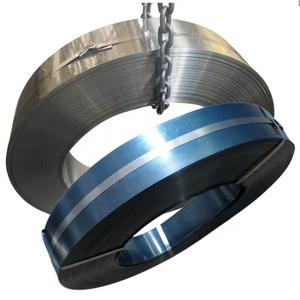

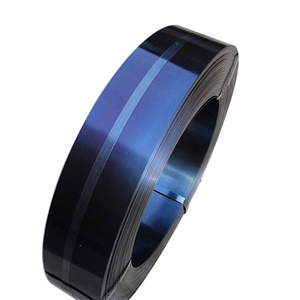

polished (blue, yellow, white, grey-blue, black, bright) or Nature etc

-

Hardness:

-

44-46hrc

-

Edge:

-

slit edge; both rounded; one side round, one side slit; square etc

-

Heat Treatment:

-

Quenching+Tempering

-

Process:

-

Tempered Steel Strip

-

Certificate:

-

ISO9001:2008/BV/TUV

-

Material:

-

Ck75,C75Cr1,Ck67,Sk5,51CrV4,Ck95,Ck100,.etc.

-

Packing:

-

Standard Seaworthy Packing

Quick Details

-

Grade:

-

Ck67ck70ck75 Sae1070 Sae1074 Aisi304 Aisi410

-

Tolerance:

-

+/-0.03mm, thickness +/-0.01mm max; width +/-0.05mm max

-

Dimensions:

-

0.20-2.5mm*10-300mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GDGW steel

-

Model Number:

-

band saw blade

-

Application:

-

saws blade, bandsaw blade

-

Processing Service:

-

heat treatment

-

Product Name:

-

c75s spring steel strip

-

Surface:

-

polished (blue, yellow, white, grey-blue, black, bright) or Nature etc

-

Hardness:

-

44-46hrc

-

Edge:

-

slit edge; both rounded; one side round, one side slit; square etc

-

Heat Treatment:

-

Quenching+Tempering

-

Process:

-

Tempered Steel Strip

-

Certificate:

-

ISO9001:2008/BV/TUV

-

Material:

-

Ck75,C75Cr1,Ck67,Sk5,51CrV4,Ck95,Ck100,.etc.

-

Packing:

-

Standard Seaworthy Packing

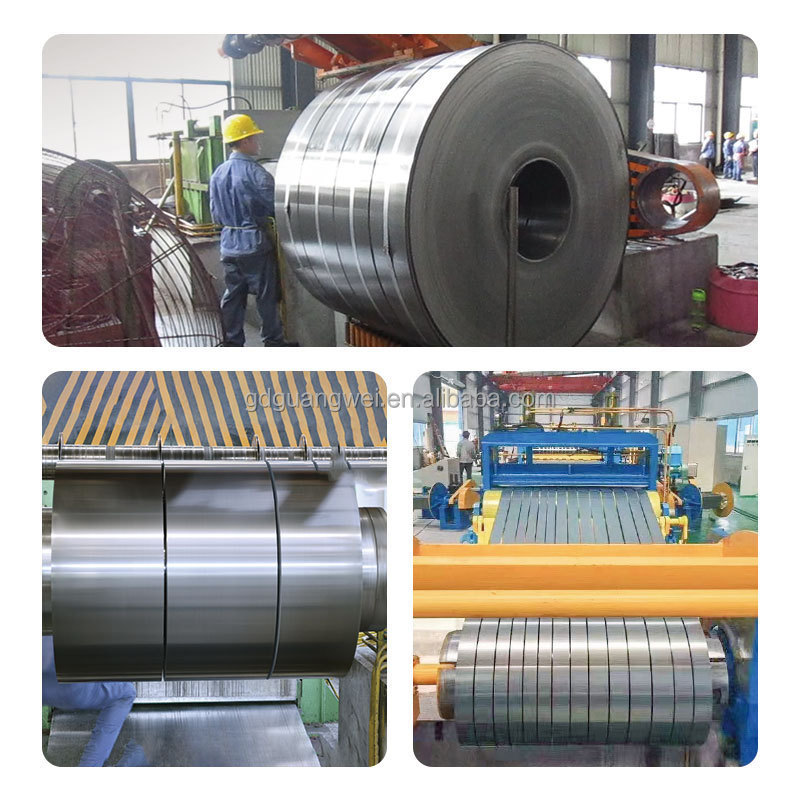

Products Description

Product Details

|

Hardened And Tempered Steel Strip Dimensions

|

|

|

|

|

||||

|

Steel Strip Product Name

|

Hardened And Tempered Steel Strip

|

|

|

|

||||

|

Hardened And Tempered Steel Strip

|

Hardening and Tempering is a thermal process that strengthens steel strips through a controlled heating and cooling process. The hardening process involves heating the steel strip to above the critical transformation temperature for the given grade and then

rapidly cooling. The steel strip in this condition is extremely brittle and requires further treatment in the tempering. Then strips are reheated to a lower temperature and holding it at the given temperature for a given period of time. This process is done in an inert atmosphere to avoid oxidation. This type of steel strip has high degree of toughness and has excellent spring properties. |

|

|

|

||||

|

Spring Steel Strip Material Grade

|

C45S C50S C55S C60S C62S C67S C70S C75S C80S C95 51CrV4 60Si2Mn 75CR1 75NI8 D6A X32 B318 AISI420

SAE1050 SAE1055 SAE1060 SAE1070 SAE1075 SAE1080 SAE1095 CK50 CKK55 CK60 CK67 CK70 CK75 CK95 65G |

|

|

|

||||

|

Spring Steel Strip Thickness

|

0.15mm-5.0mm

|

|

|

|

||||

|

Spring Steel Strip Width

|

2mm - 510mm

|

|

|

|

||||

|

Spring Steel Strip Hardness

|

29-55HRC

|

|

|

|

||||

|

Spring Steel Strip Surface

|

blue, white, gold, polished etc.

|

|

|

|

||||

|

Spring Steel Strip Edge

|

slit, rounded, square

|

|

|

|

||||

|

Spring Steel Strip Application for

|

1. spring steel strip for band saw blade

2. carbon steel sheet for circular saw blade 3. alloy steel sheet for gang saw blade 4. hardened and tempered steel strip for trowel 5. puertas enrollables

these strips are widely used for making all kinds of saw blade(wood band saw blade, circular saw blade, gang saw blade, jig saw blade etc.), steel springs, metal parts, clips, hand tools, construction tools, auto spare parts, coil springs,steel for masonary tools which do not require severe bending or forming

|

|

|

|

||||

|

Standard

|

DIN 172222

|

|

|

|

||||

|

Sample and Price

|

Ms. Choco (whatsAPP/Mob: +86-13828430544 band saw blade factory)

|

|

|

|

||||

Strictly Quality Test Before Delivery

---Cgood steel well know the most import features of the hardened and tempered steel strip material, so we will test

1)hardness test

2)flatness test

3)straightness test

4)thickness test

5)width test

6)Microstructure test (according to customer's requirement)

7)Chemical composition test (according to customer's requirement)

during and after the production, so that we can make sure our material suitable for customer's requirements.

7)Chemical composition test (according to customer's requirement)

Hardness test for hardened and tempered steel strip

Cgood steel will make the hardness test during the production, so that we can keep

uniform hardness

of all materials that we produce, we will strictly control on our quality. All materials shall be measured on customer's requirement scale.

Flatness test for

hardened and tempered steel strip

The unflatness across the strip (also called cross camber and cross bow) is expressed as a percentage of the strip width. The unflatness along the strip, sometimes called coil-set, is also expressed as a percentage. Unless otherwise agreed upon the measuring length = the strip width for flatness measurements along and across the strip. Influence of possible residual stresses from slitting shall be excluded.

Tolerance Maximum permitted deviation class

P1 0.4mm

P2 0.3mm

P3 0.2mm

P4 0.1mm

Straightness test for hardened and tempered steel strip

Straightness deviation is specified in millimeters and defined as lateral deviation of the edge from a straight line as shown in

the graphic. The straightness deviation is stated as edge camber(bow) and measured over a strip length of 1 or 3 meters. Straightness tolerance depends on the strip width and is given as one of five straightness classification groups (R).

|

Tolerance class

|

Strip Width

|

|

|

|

|

|

|

|

|||||||

|

|

8 - (20) mm

|

|

20 - (50) mm

|

|

50 - (125) mm

|

|

125mm~

|

|

|||||||

|

|

Measuring length

|

|

|

|

|

|

|

|

|||||||

|

|

1m

|

3m

|

1m

|

3m

|

1m

|

3m

|

1m

|

3m

|

|||||||

|

|

Maximum allowed straightness deviation (mm)

|

|

|

|

|

|

|

|

|||||||

|

R1

|

5

|

45

|

3.5

|

31.5

|

2.5

|

22.5

|

2

|

18

|

|||||||

|

R2

|

2

|

18

|

1.5

|

13.5

|

1.25

|

11.3

|

1

|

9

|

|||||||

|

R3

|

1.5

|

13.5

|

1

|

9

|

0.8

|

7.2

|

0.5

|

4.5

|

|||||||

|

R4

|

1

|

9

|

0.7

|

6.3

|

0.5

|

4.5

|

0.3

|

2.7

|

|||||||

|

R9

|

As per customer`s special requirement

|

|

|

|

|

|

|

|

|||||||

Thickness test for hardened and tempered steel strip

According to our standard tolerance on thickness for +/- 0.015-+/-0.07mm for different thickness requirement

|

Thickness tolerance

|

|

|

|

|

||||

|

Thickness mm

|

|

Standard tolerance +/- mm

|

|

|

||||

|

<0.25

|

|

+/-0.015

|

|

|

||||

|

0.25-0.40

|

|

+/-0.020

|

|

|

||||

|

0.40-0.60

|

|

+/-0.025

|

|

|

||||

|

0.60-0.90

|

|

+/-0.030

|

|

|

||||

|

0.90-120

|

|

+/-0.040

|

|

|

||||

|

1.20-1.60

|

|

+/-0.050

|

|

|

||||

|

1.60-2.10

|

|

+/-0.055

|

|

|

||||

|

2.1.0-2.60

|

|

+/-0.060

|

|

|

||||

|

2.60-3.20

|

|

+/-0.065

|

|

|

||||

|

3.20-5.00

|

|

+/-0.070

|

|

|

||||

|

Thickness mm

|

Width tolerance +/- mm

|

Width tolerance +/- mm

|

|

|

|||

|

Thickness mm

|

<50

|

50-100

|

100-200

|

200-500

|

|||

|

<0.30

|

+/-0.30

|

+/-0.35

|

-

|

-

|

|||

|

0.30-0.60

|

+/-0.20

|

+/-0.30

|

+/-0.50

|

+/-0.80

|

|||

|

0.60-1.20

|

+/-0.20

|

+/-0.25

|

+/-0.50

|

+/-0.80

|

|||

|

1.20-1.60

|

+/-0.20

|

+/-0.25

|

+/-0.50

|

+/-0.80

|

|||

|

1.60-3.20

|

+/-0.20

|

+/-0.25

|

+/-0.50

|

+/-0.80

|

|||

Microstructure test for hardened and tempered steel strip

Cgood hardened and tempered steel strip shall be fully hardened and tempered with non-dissolved carbides uniformly distributed in a tempered martensitic matrix.

Hot Searches