- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

4 - 25

-

Marketing Type:

-

Hot Product 2022

-

Coil Weight (T):

-

15 T

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380 v 50HZ 3 phase

-

Rated Power:

-

180kw

-

Dimension(L*W*H):

-

40000x7500x2000mm

-

Weight:

-

35000

-

Year:

-

2022

-

thickness for material:

-

0.3MM to 6MM

-

material width:

-

900-1600mm

-

Loading weight:

-

max 25 tons

-

cutting precision:

-

0.5MM/M

-

Speed:

-

30-60m/min

Quick Details

-

Cutting Width (mm):

-

900 - 1600 mm

-

Material Thickness(mm):

-

0.3 - 6 mm

-

Cutting Speed(m/min):

-

30000 - 60000 mm

-

No. of Slitting Lines:

-

4 - 25

-

Marketing Type:

-

Hot Product 2022

-

Coil Weight (T):

-

15 T

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380 v 50HZ 3 phase

-

Rated Power:

-

180kw

-

Dimension(L*W*H):

-

40000x7500x2000mm

-

Weight:

-

35000

-

Year:

-

2022

-

thickness for material:

-

0.3MM to 6MM

-

material width:

-

900-1600mm

-

Loading weight:

-

max 25 tons

-

cutting precision:

-

0.5MM/M

-

Speed:

-

30-60m/min

Product Certification

CE Certified.Valid from 2020-07-18 until 2025-07-18

Packaging & Delivery

Selling Units: Single item

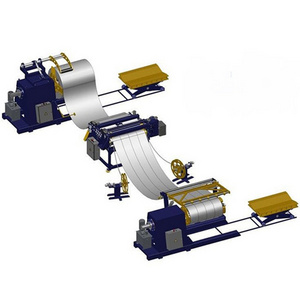

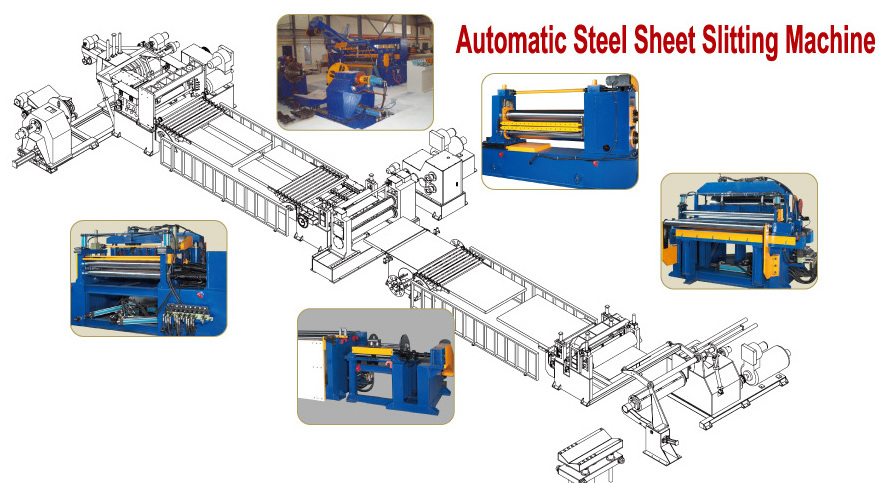

| No | Name | Quantity |

| 1 | Entry coil car | 1 |

| 2 | Hydraulic Decoiler | 1 |

| 3 | Press and pinch device | 1 |

| 4 | Hydraulic cutter | 1 |

| 5 | Anti-Tracking Device | 1 |

| 6 | Slitter | 1 |

| 7 | Scrap winder | 1 |

| 8 | Tension stand | 1 |

| 9 | Recoiler | 1 |

| 10 | Exit coil car | 1 |

| 11 | Hydraulic system | 1 |

| 12 | Electrical system | 1 |

Hydraulic de-coiler

Structure: Hydraulic expand and shrink to tight the inner hole of steel coils.

Specification: Φ520max/480min×1250 ( width of roller )

The max capacity: 15T, with simple supporting stand.

Function: Fixed the coil to achieve unwinding function, with the brake. The car makes the inner holes of steel coils aim at the de-coiler center. The hydraulic cylinder drive the center shaft hydraulic ally to tight the inner hole of steel coil.

Hydraulic press and pinch device

Two hydraulic cylinders controlled unwinding rubber roller lifting.

Cycloid reducer BWY215-121 drive the running of steel coil.

Hydraulic pressing & guiding device: Driven by 11KW cycloid reducer motor. Setting manual clutch. Pinch roller pressed by hydraulic cylinders.

Drive mode using the lower roller drive. The diameter of hydraulic cylinder is: φ100

Structure: It is welding by steel plates and profiled bar.

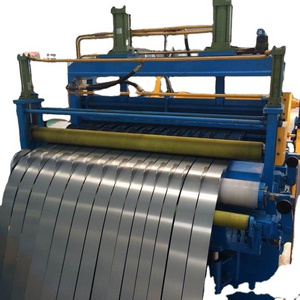

As to the slitting part:

Specification of blades: Φ360×Φ220×15 material : 6CrW2Si and 10 pieces of blades and a set of spacers and rubber ring will be provided with the machine for free, Details please check the spare parts list.

Thickness of process able material: δ = 4mm.

Width of process able material: B≤1250

Electric motor: Electric motor : 45KW frequency conversion control motor to control the speed. Control mode is frequency control.

Reducer: cycloidal reducer

The slitting machine is designed with entry guide device, press device

Function: It equips the side guide device, to achieve positioning strip and stop the jumping of strip. Improve the accuracy of slitting. It can shear actively or passively. To achieve different strip thickness accuracy requirements of slitting.

Tension stand

1)

The frame welded by steel plates

2)Consist of base ,pre-dividing shaft, bracket, press shaft, hydraulic damp device and hydraulic shaft lifting the press down device. Supporting slices, spacers and etc.

3)It is equipped with the transition table which is driven by hydraulic and is used to make the finished strips pass easily.

4)Function: It also have the side guide device for finished strips and prevent them from jumping and improve the recoiler quality. To establishing a stretching force with recoilier, to make sure the even quality and tight of steel coils after recoiling

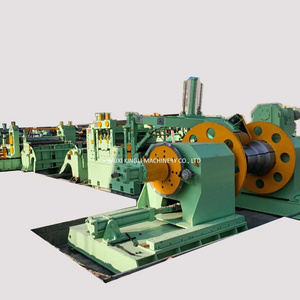

Recoiler

1)

Structure:hydraulic expand and shrink model

2)

Motor:

90

KW

3)

Overall steel plate cantilever structure

4)

Function: It cooperates with the finished steel strips after first pre-dividing and second dividing to insure the even and tight quality of recoiler. Recoiling tension adjustable, Recoiling speed adjustable.

Product Features

1. More efficient and accurate execution of production orders

;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.