- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Material:

-

Si3N4,ZrO2,Sic

-

Lubrication:

-

Oil-free Self-lubricating

-

Material of balls:

-

Ceramic Material Zro2/si3n4

-

Number of Row:

-

Single Row

-

Seals Type:

-

Open 2RS ZZ

-

Application:

-

Food Machinery

-

Cage:

-

Nylon PTFE UPE PA

-

Package:

-

Single box packing

-

Special bearing:

-

High temperature bearing

-

Vibration Level code:

-

V1,V2.V3

Quick Details

-

Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use, Retail, Construction works , Energy & Mining, Advertising Company

-

Brand Name:

-

ZYSL

-

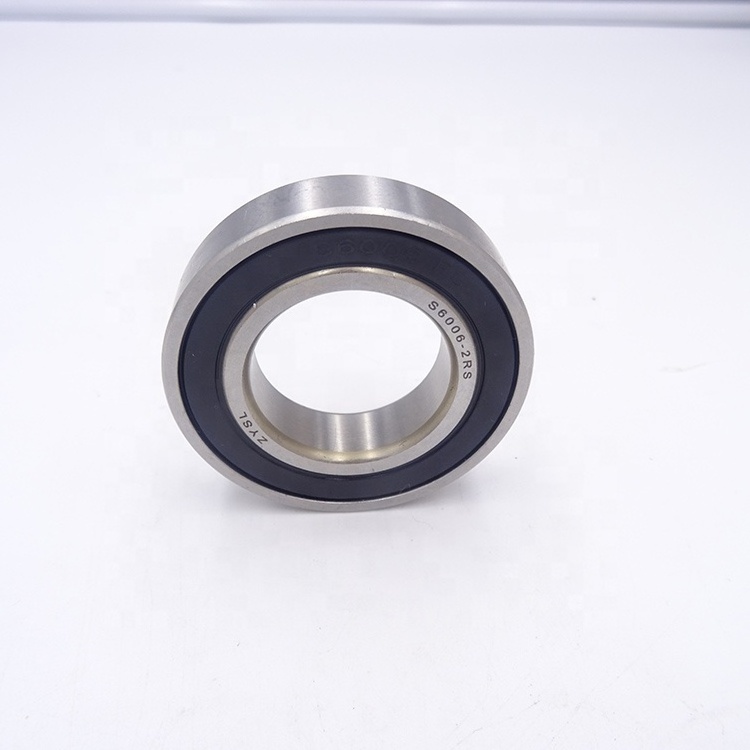

Model Number:

-

6006 2rs

-

Place of Origin:

-

China

-

Material:

-

Si3N4,ZrO2,Sic

-

Lubrication:

-

Oil-free Self-lubricating

-

Material of balls:

-

Ceramic Material Zro2/si3n4

-

Number of Row:

-

Single Row

-

Seals Type:

-

Open 2RS ZZ

-

Application:

-

Food Machinery

-

Cage:

-

Nylon PTFE UPE PA

-

Package:

-

Single box packing

-

Special bearing:

-

High temperature bearing

-

Vibration Level code:

-

V1,V2.V3

ZYSL is a specialized manufacturer of Ceramic Bearing. Full Complement ceramic bearings,Ceramic Bal ls.

Hybrid Ceramic Bearing:

Ceramic bearings offer a significant performance improvement from those made from traditional steel. Our ceramic bearings are manufactured from silicon nitride (Si3N4), an exceptionally hard non-metallic material rated for speeds to 2 million dN, offering a wide selection of benefits.

Hybrid Bearings have steel rings and ceramic balls. Si3N4 Ball is the most popular for the balls as it has only 40 percent of the density of bearing steel but is much harder giving greater wear resistance. Zirconia is heavier with 75 percent of the density of steel so is less suitable for hybrid bearings..

Full Ceramic Bearing:

Full Ceramic Bearings are made entirely of ceramic material and are superior to common steel bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM’s, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present. Applications such as cryopumps, medical devices, semiconductors, machine tools, turbine flow meters, food processing equipment, robotics and optics. Ceramic materials commonly used for bearings are Silicon Nitride (Si3N4), Zirconia Oxide (ZrO2), or Silicon Carbide (SiC.)

Ceramic Balls:

We are special in making Silicone Nitride Balls (Si3N4 Balls,Zicronia Balls (ZrO2 Balls),Sic Ceramic Balls , Aluminum Oxside Valve (AI203) ceramic balls.

Compared with steel, ceramic materials are noted for their better or particular characters, such as wear-resistance, corrosion resistance, high temperature resistance, electrical insulation (except SiC), non-magnetic, high strength, high rigidity, and low specific gravity. These properties qualify them for replacing steel to make bearings serve in conditions of higher speed, harsh environment and less lube, and decrease wear, noise, vibration and maintenance time of bearings, and eventually increase performance, reliability and life of bearings.

|

Brand |

ZYSL Bearings |

||

|

Name |

6006 rubber sealed 30*55*13mm Hybrid ceramic Si3N4 balls stainless steel inner and outer for bike |

||

|

Model |

60 series, 62 series, 63 series, 67 series, 68 series and 69 series... |

||

|

511 series and all kinds of thrust bearing. |

|||

|

70 series, 72 series and 79 series. |

|||

|

Material |

Ceramic |

Certificate |

ISO9001:2001 |

|

Precision |

P0, P6, P5, P4 |

||

|

Bore Size: |

2mm-100mm |

Outside diameter |

5mm-200mm |

|

Clearance |

C0,C1,C2,C3,C4,C5 etc. |

||

|

Cage Type |

PTFE, Nylon, PEEK |

||

|

Seals Type |

ZZ,RS, 2RS, R2, Z, 2Z, 2RZ etc |

||

|

Features |

low density, strong solidity, low friction coefficient, abrasion resistance, magnetic resistance, acid and alkali resistance, good resistance to wear and tear, electric insulation, self-lubrication, temperature resistance of over 300C, high speed rolling rates, cool temperatures, light weight (60% lighter than steel), elasticity (50% higher than steel), and a long service life (3 to 5 times longer than full chrome steel bearings). |

||

|

Application |

Electro plating, electro polishing ,Food processing, vacuum applications.Fiber processing, conveyor processing. Medical radiation, photo processing,Computer assembly, electronics applications, Medicine equipment, wet applications. |

||

|

Package |

pallet, wooden case,industrial package or as customers' requirement |

||

|

Price |

FOB, CFR, CIF |

Delivery Time |

5-10 days |

The Advantage of products

1.

High precision bearings,P4 ,P5 and P6.

2

.Rings are made of refined Chrome steel.stainless steel 440C

3

.Cage:Peek & PTFE cage .(can assure constant working under 250 centigrade)and peek cage also is the ideal cage for the high speed as it can provide the lubrication during bearing working, and it has the property of self-lubrications.However for normal applications, steel cage and Nylon cage is enough.

4

. Balls: we use G3,G5 high precision Si3N4 ball for the high speed.

5

. Radial clearance: Normal C0,or C3.

6

.Not only for the high speed, but also Hybrid bearings has the

insulation functions. Hence for the small size of bore dia.40mm ,

also can be used for the insulation bearing purpose.

7

.Full ball hybrid also can be produce as per our production picture.

All-ceramic bearings have good to excellent corrosion resistance, are non-magnetic and, apart from silicon carbide, are electrically insulating. All-ceramic bearings can be used in high to very high temperatures if supplied without a cage (full complement).

Electrical resistance: Si3N4 best, then ZrO2, then SIC which is conductive.High temp resistance:

SiC best (1100C), then Si3N4 (1000C), then ZrO2 (400C) Corrosion resistance:

SIC (excellent), then Si3N4 (very good) and ZrO2 (good)Load capacity:

SIC highest then Si3N4, then ZrO2 Fracture toughness:

ZrO2 best, then Si3N4, then SiC

All-ceramic bearings have lower load and speed ratings than steel or hybrid bearings. The speeds are lower due to the lower precision and roundness of the rings and the loads are lower because the material is more brittle. Under heavy loads and particularly heavy shock loads, there is a risk of cracking. For the same reason, great care should be taken with interference fits. Zirconia is the least brittle so it will handle shock loads and very small interference fits better than the other ceramic materials with silicon carbide being the most brittle. Shock loads should be avoided with all-ceramic bearings. Great care should be taken when using ceramic bearings (especially silicon nitride and silicon carbide) on steel shafts at high temperature due to the difference in expansion coefficient and the relative brittleness of ceramics.