- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Thermosetting Plastic

-

Application:

-

Auto Parts

-

Certificate:

-

ISO9001:2008.ROHS

-

Feature:

-

High-performance Polymer

-

Usage:

-

Injection Molding Products

-

Sample:

-

Freely

-

Packing:

-

25kg/bag

-

MOQ:

-

NO

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LFT-G

Quick Details

-

Model Number:

-

PLA-NA-LGF40

-

Product name:

-

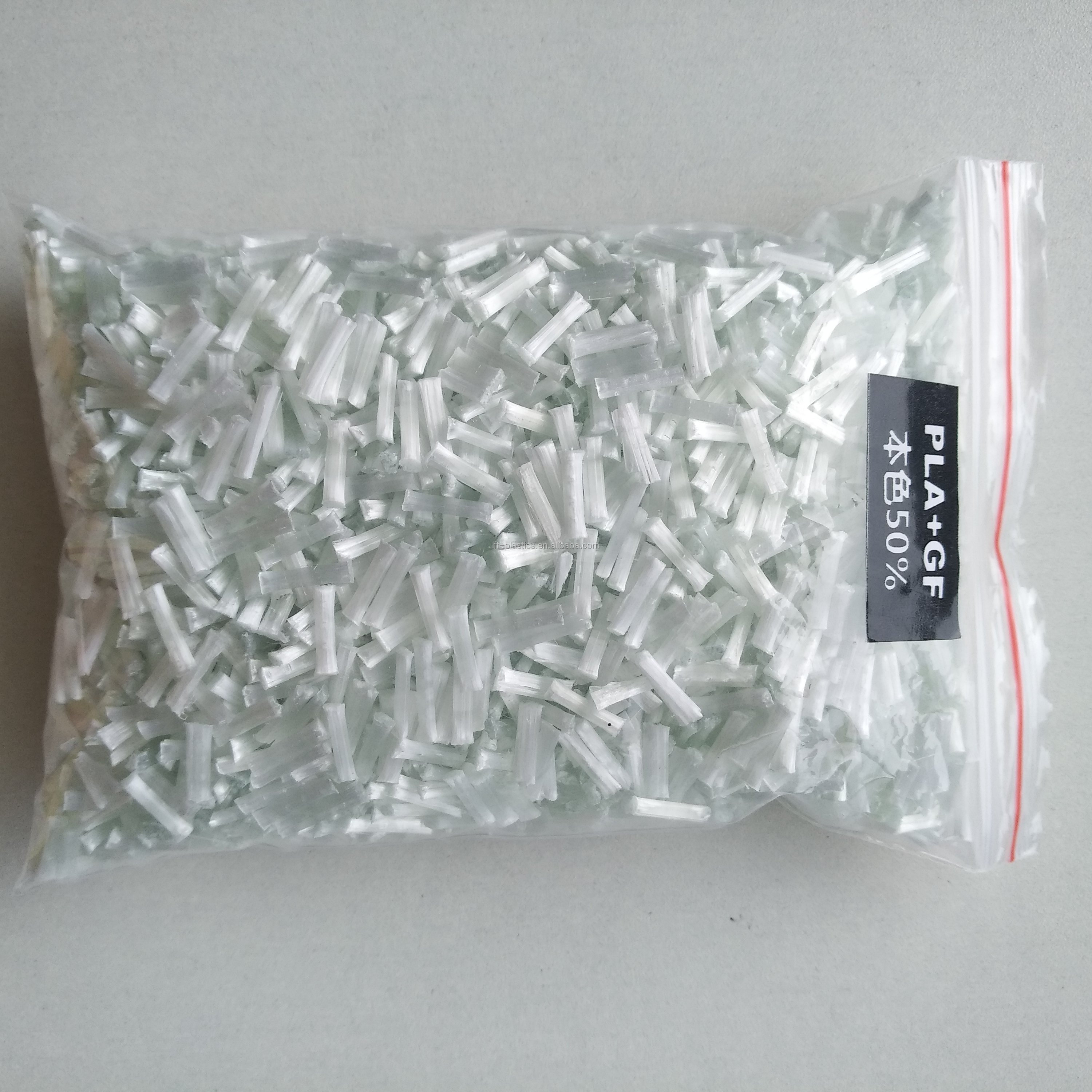

PLA Long Glass Fiber40 Granule

-

Color:

-

Natural

-

Type:

-

Thermosetting Plastic

-

Application:

-

Auto Parts

-

Certificate:

-

ISO9001:2008.ROHS

-

Feature:

-

High-performance Polymer

-

Usage:

-

Injection Molding Products

-

Sample:

-

Freely

-

Packing:

-

25kg/bag

-

MOQ:

-

NO

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LFT-G

|

Product Name

|

PLA Raw resin filled long glass fiber granule

|

|

|

|

Color

|

natural(as cutomerized)

|

|

|

|

Product number

|

PLA-NA-LGF40

|

|

|

|

Advantage

|

high toughness ,low warpage,creep resistance

|

|

|

|

MOQ

|

1Ton

|

|

|

|

Shipment Port

|

XIAMEN

|

|

|

|

Delivery Time

|

3-15 days after payment

|

|

|

|

Packing Details

|

20-25kg/bag(also as customer required)

|

|

|

|

After Sales Services

|

24 hours on line

|

|

|

PLA 40% long glass fiber injection molding grade reinforced thermoplastic

Pla polylactide with LGF Long glass fiber is a new type of biodegradable material made from starch raw materials proposed by renewable plant resources such as corn. The starch PLA with long glass fiber raw material is obtained by saccharification to obtain glucose, and then glucose and a certain strain are fermented to produce high-purity lactic acid, and then a certain molecular weight polylactic acid is synthesized by chemical synthesis. Long glass fiber with PLA has good biodegradability, can be completely degraded by microorganisms in nature after use, and finally produces carbon dioxide and water, which does not pollute the environment. This is very beneficial to the environment and is recognized as an environmentally friendly material. Caring for the Earth, you and I are responsible. According to the news, the global temperature will rise to 60 °C in 2030. The treatment of ordinary plastics is still incineration and cremation, causing a large amount of greenhouse gases to be discharged into the air, while polylactic acid plastics are buried in the soil to degrade and produce The carbon dioxide directly enters the soil organic matter or is absorbed by the plant and will not be discharged into the air without causing a greenhouse effect.

Long fiber thermoplastic materials have obvious enhancement effects on the mechanical properties, electrical properties and thermal properties. The long fiber reinforced thermoplastic material adopts a Injection molding process which combines the fiber with the matrix resin to achieve the best performance. This is mainly due to the short fibers in the mixed flow direction, long fiber, lower performance is good, long fiber mixed in, filling mould flip, bend, make all aspects of its performance is higher than that of short fiber. Therefore, long fiber mixed die products have higher uniformity, more direct and shorter yield, which is the most important factor in fiber reinforced composites compared with fiber length fiber length.