- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JIA GU

-

Model Number:

-

HY933,HY 935,HY 936

-

Type:

-

MS sealant

-

Product name:

-

HY 933 935 936 MS sealant

-

Main material:

-

MS

-

Application:

-

Automotive industry

-

Component:

-

Single component

-

Surface dying time (min):

-

30

-

Curing speed(mm/24h):

-

3~4

-

Appearance:

-

Thixotropic paste

-

Advantage:

-

Green friendly

-

Feature:

-

Primer free

-

Certificate:

-

ROHS REACH

Quick Details

-

CAS No.:

-

75009-88-0

-

Other Names:

-

modified silane

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JIA GU

-

Model Number:

-

HY933,HY 935,HY 936

-

Type:

-

MS sealant

-

Product name:

-

HY 933 935 936 MS sealant

-

Main material:

-

MS

-

Application:

-

Automotive industry

-

Component:

-

Single component

-

Surface dying time (min):

-

30

-

Curing speed(mm/24h):

-

3~4

-

Appearance:

-

Thixotropic paste

-

Advantage:

-

Green friendly

-

Feature:

-

Primer free

-

Certificate:

-

ROHS REACH

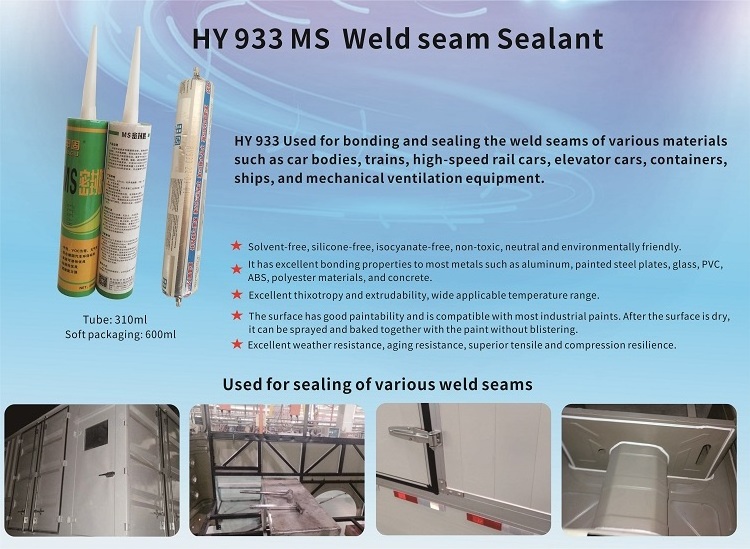

Ms polymer Adhesive and Sealant for Transport

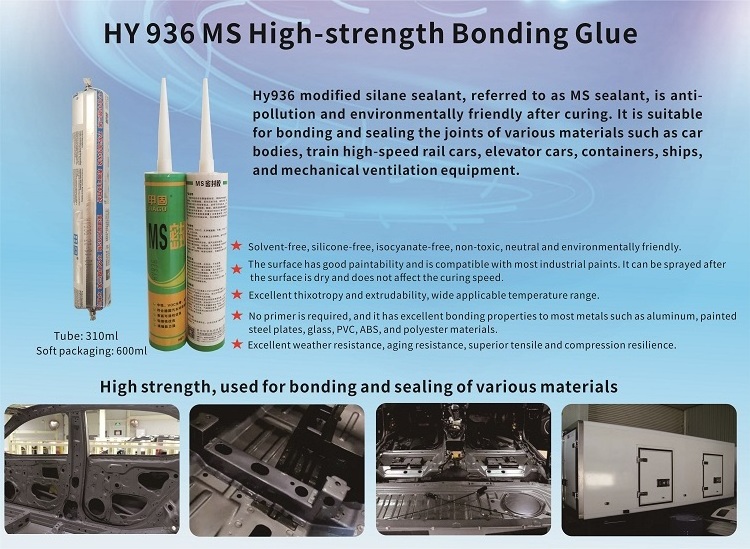

Modified silane polyethers, better known as MS polymers make exceptional adhesives and sealants for many industries among which transport vehicle assembly. MS polymer adhesives and sealants get their inspiration from silicone and polyurethane based systems while cancelling out most of the disadvantages associated with them.

MS polymer sealants and adhesives make transport vehicle assembly safer, more efficient and more reliable. They are also free of solvents, silicone and isocyanates which all are considered harmful to humans and the environment .

MS polymer sealants and adhesives make transport vehicle assembly safer, more efficient and more reliable. They are also free of solvents, silicone and isocyanates which all are considered harmful to humans and the environment .

Product Features

Paintable and

Primerless

Excellent bond strength

Suitable for bonding to a wide range of surfaces

High levels of elasticity

Excellent chemical resistance

No bubble formation

Easy to use, even at low temperatures

No solvent, no PVC, no isocyanate, non-toxic, odorless, non-polluting, neutral and environmentally friendly.

No bubble formation

Easy to use, even at low temperatures

The surface has good paintability and is compatible with most industrial paints.

It can be painted after surface drying without affecting the curing speed.

Excellent thixotropy and extrudability, suitable for a wide temperature range.

No primer is required, and it has excellent adhesion to most metals such as aluminum and painted steel, as well as glass, PVC, ABS, and polyester materials.

Excellent weather resistance, aging resistance, excellent tensile and compression recovery.

Application

HY933 Ms polymer sealant is

mainly used for caulking and sealing of body and container welds and seams joints, sealing for RV roof

HY935

MS polymer systems are used for sealing floors, roofs and side panels of vehicles,

assembly of the windshield

Their flexibility allows for high performance, whereas the minimum surface preparation and ability to bond dissimilar materials guarantee assembly efficiency.

It also could be used for sealing and bonding vehicle windows and windshields. The flexibility of MS polymer adhesives and sealants guarantee high performance on windows and windshields of vehicles.

HY936 MS polymer structural adhesive ,

high modulus, high strength, used for windshield bonding, can reach the expected stress in a short time.

It offer a strong and easy to apply system for bonding bus frames, truck cabins and body structures of trains.

|

Model

|

HY933

|

HY935

|

HY936

|

||

|

Appearance

|

White, gray, black and other fine and uniform pastes

|

|

|

||

|

Density (g/cm3)

|

1.45±0.1

|

|

|

||

|

Sag(mm)

|

0

|

|

|

||

|

TFT(min)

|

20~90

|

|

|

||

|

Curing speed (mm /24h)

|

3.0

|

|

|

||

|

Tensile shear strength (Mpa)

|

1.2

|

2.0

|

4.0

|

||

|

Tensile strength (Mpa)

|

5

|

5

|

10

|

||

|

Elongation at break (%)

|

400

|

400

|

300

|

||

|

Tear strength (KN /m)

|

5

|

5

|

10

|

||

|

Hardness (Shore A)

|

30~60

|

30~60

|

40~70

|

||

|

Temperature resistance (℃)

|

-40~120

|

|

|

||

Operation Process

1. The surface of the joint should be free of oil stains, dust, impurities, etc.

2. Cut the glue nozzle into the required size and shape according to the process requirements;

3. Cut off the sealant seal, install the glue nozzle, and put it into the glue gun;

4. Apply the sealant evenly on the joints, the thinnest part is greater than 1mm; when using the pneumatic gun, the air pressure is controlled at 0.3~0.5Mpa;

5. The product can be colored by traditional methods after surface drying, including epoxy resin and acrylic paint.

2. Cut the glue nozzle into the required size and shape according to the process requirements;

3. Cut off the sealant seal, install the glue nozzle, and put it into the glue gun;

4. Apply the sealant evenly on the joints, the thinnest part is greater than 1mm; when using the pneumatic gun, the air pressure is controlled at 0.3~0.5Mpa;

5. The product can be colored by traditional methods after surface drying, including epoxy resin and acrylic paint.

Packing & shipping

:

600ml / Sausage 20 / carton

Certifications

R & D

In the field of adhesives, we are not only a manufacturer, but also a total solution provider covering bonding, sealing and potting processes.

Since its establishment, our company has always adhered to the scientific development concept, and regards technology research and development and personnel training as the company's development goals. Our company has set up a special technical research and development department, and has a technical research and development team with high education, rich experience and strong innovation ability. The company has 6 senior engineers, 4 intermediate engineers and 10 professional technicians, with an average age of about 40 years old. The company pays attention to the recruitment and training of talents. The company recruits technical R&D personnel for a long time and continuously enriches the R&D team. At the same time, the company regularly conducts professional training for existing talents, and also arranges organizations to observe and study in other enterprises, so as to continuously improve the professionalism of R&D personnel. knowledge and innovation. The company also attaches great importance to the research and development of new products. Every year, it invests a lot in the research and development of new products and has achieved great results.

Exhibition

Hot Searches