- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor, pond, landfill, mine etc, Landfill, Fish farm pond, Roof waterproofing, swimming pool

-

Design Style:

-

Industrial

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

OEM

-

Model Number:

-

0.5mm-2.5mm

-

Product Name:

-

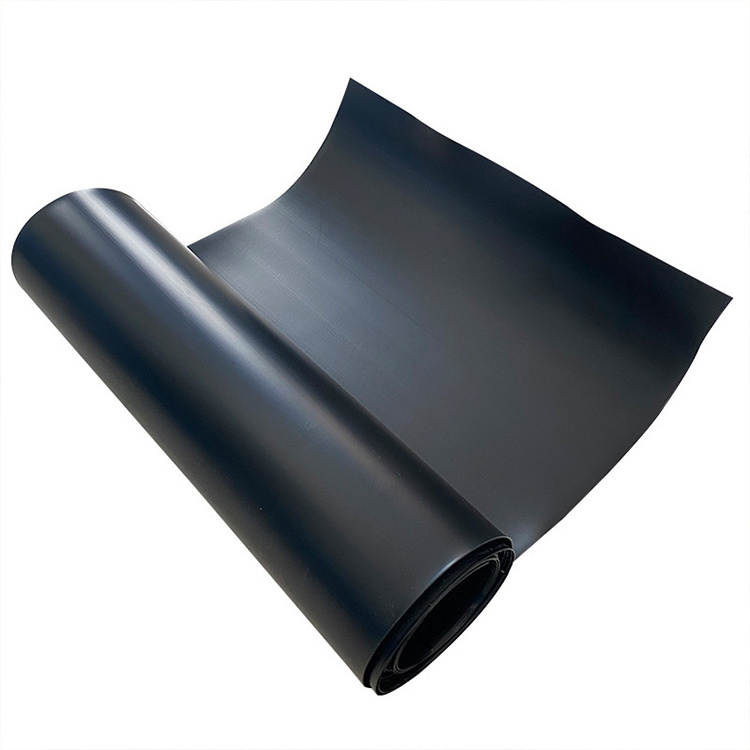

1.5mm 2.0mm HDPE Geomembrane liner for shrimp farming

-

Color:

-

Black white blue or as required

-

Material:

-

HDPE LDPE LLDPE EPDM EVA

-

Thickness:

-

0.5-2.5mm

-

Length:

-

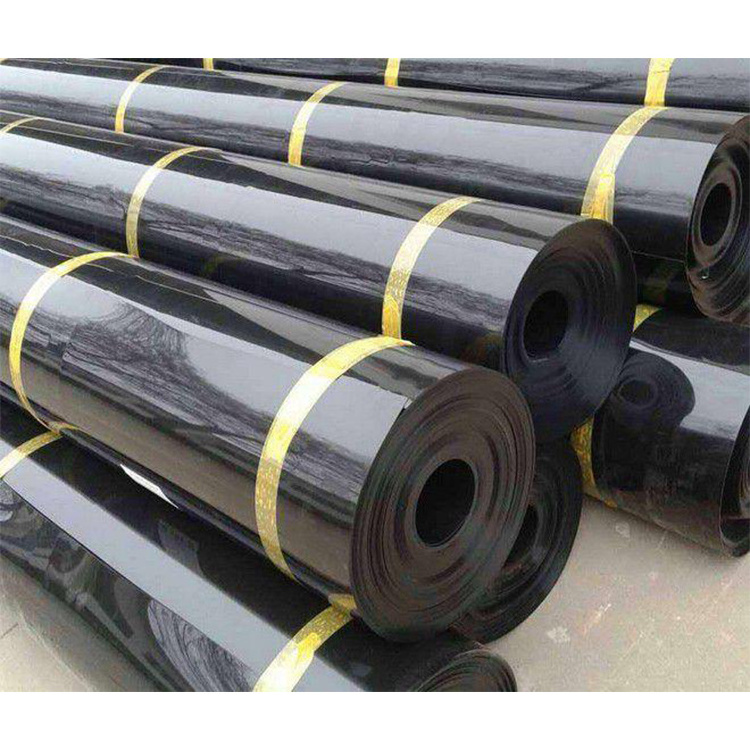

50-200m/roll or as requirement

-

Width:

-

2m-8m

-

Package:

-

Woven Bags or as requirement

-

Standard:

-

GB/T 17643-2011/GRI GM13

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Outdoor, pond, landfill, mine etc, Landfill, Fish farm pond, Roof waterproofing, swimming pool

-

Design Style:

-

Industrial

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

OEM

-

Model Number:

-

0.5mm-2.5mm

-

Product Name:

-

1.5mm 2.0mm HDPE Geomembrane liner for shrimp farming

-

Color:

-

Black white blue or as required

-

Material:

-

HDPE LDPE LLDPE EPDM EVA

-

Thickness:

-

0.5-2.5mm

-

Length:

-

50-200m/roll or as requirement

-

Width:

-

2m-8m

-

Package:

-

Woven Bags or as requirement

-

Standard:

-

GB/T 17643-2011/GRI GM13

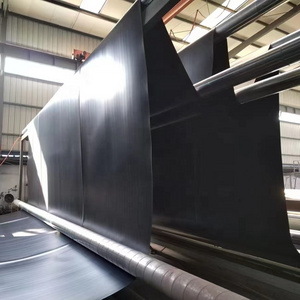

Products Description

1) Thickness: smooth surface 0.2mm - 3.0mm, textured surface 1.0-2.0mm

2) Width: smooth furface 1m-8m, rough surface 4m-8m

3) Length: 50m-200m/ roll or as requested.

4) Material: HDPE, LDPE, LLDPE

5) Color: black, white, blue, green.

6) Optional surface: smooth surface, single surface textured, dual surfaces textured.

2) Width: smooth furface 1m-8m, rough surface 4m-8m

3) Length: 50m-200m/ roll or as requested.

4) Material: HDPE, LDPE, LLDPE

5) Color: black, white, blue, green.

6) Optional surface: smooth surface, single surface textured, dual surfaces textured.

|

Thickness

|

0.75

|

1

|

1.25

|

1.5

|

2

|

2.5

|

3

|

|

Density g/m2

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

|

Tensile yield strength (N/mm)

|

≥11

|

≥15

|

≥18

|

≥22

|

≥29

|

≥37

|

≥44

|

|

Tensile breaking strength (N/mm)

|

≥20

|

≥27

|

≥33

|

≥40

|

≥53

|

≥67

|

≥80

|

|

Bongation at yield(%)

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

|

Elongation at break(%)

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

|

Tear resistance(N)

|

≥93

|

≥125

|

≥160

|

≥190

|

≥250

|

≥315

|

≥375

|

|

Puncture strength(N)

|

≥240

|

≥320

|

≥400

|

≥480

|

≥640

|

≥800

|

≥960

|

|

Tensile load stress cracking

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

|

Carbon black content(%)

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

Features:

1) Good physical and mechanic performance

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4) Good adaptability to high and low temperature, non-toxicity, long service life

5) Good waterproof, drainage, anti-seepage and damp proof effects

6) Complete width and thickness specifications, low cost and easy installation.

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4) Good adaptability to high and low temperature, non-toxicity, long service life

5) Good waterproof, drainage, anti-seepage and damp proof effects

6) Complete width and thickness specifications, low cost and easy installation.

Benefits:

* The most chemically resistant member of the polyethylene family due to its dense configuration.

* Field welded with hot wedge welders and extrusion welders. These factory quality welds are virtually stronger than the sheet itself.

* The best QC-QA testing capabilities in the marketplace.

* No need to cover the liner because it is UV stable and cost-effective.

* Available in roll stock and come in varying thicknesses ranging from 20 to 120 mil depending on your requirements.

* Field welded with hot wedge welders and extrusion welders. These factory quality welds are virtually stronger than the sheet itself.

* The best QC-QA testing capabilities in the marketplace.

* No need to cover the liner because it is UV stable and cost-effective.

* Available in roll stock and come in varying thicknesses ranging from 20 to 120 mil depending on your requirements.

Product Application

Why Choose Us?

Hot Searches