Six cores-Seiko Seiko Seizao

● Full-mirror stainless steel curved light liner design, energy saving and heat preservation.

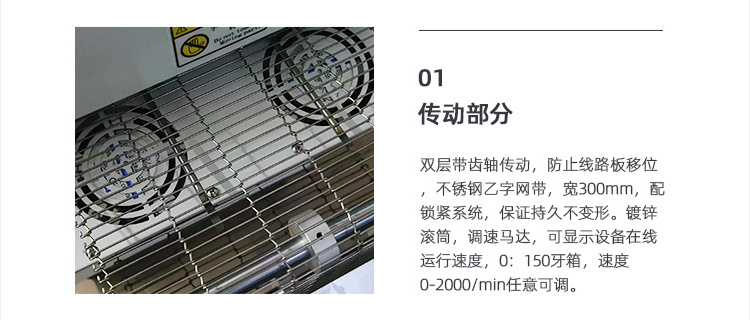

● Double-layer toothed shaft transmission is adopted to effectively prevent the displacement of the circuit board

● Stainless steel mesh belt is resistant to high temperature, acid and alkali, abrasion and high rigidity.

● Imported intelligent temperature controller and unique PID digital precise control function can easily save electricity and cost.

● Imported components make the control system more stable and reliable.

● Factory direct sales and after-sales service are guaranteed.

- Product Details

- {{item.text}}

Quick Details

-

Use:

-

PCB solder

-

Voltage:

-

5-wire 3-phase 380V or single-phase 220V 50/60Hz

-

Dimensions:

-

L1400 W612 H650mm

-

Rated Duty Cycle:

-

1.5kw

-

Weight (KG):

-

160 KG

-

Model number:

-

RF-330 (Three temperature zone)

-

Number of heating zones:

-

3

-

Length of heating area:

-

1000mm

-

Heating method:

-

Full hot air

-

Number of cooling zones:

-

1

-

Maximum width of PCB:

-

300mm

-

Normal Power:

-

4Kw

-

Transporter belt height:

-

880±20mm

-

Transfer method:

-

Net drive

-

Conveyor belt speed:

-

0-2000mm/min

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DGenergy

-

Use:

-

PCB solder

-

Voltage:

-

5-wire 3-phase 380V or single-phase 220V 50/60Hz

-

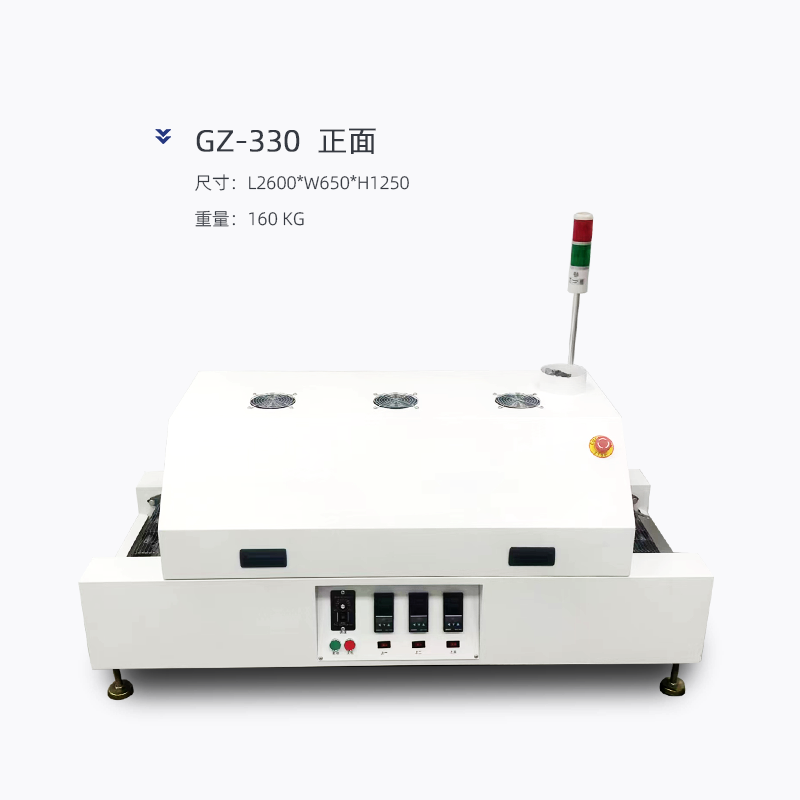

Dimensions:

-

L1400 W612 H650mm

-

Rated Duty Cycle:

-

1.5kw

-

Weight (KG):

-

160 KG

-

Model number:

-

RF-330 (Three temperature zone)

-

Number of heating zones:

-

3

-

Length of heating area:

-

1000mm

-

Heating method:

-

Full hot air

-

Number of cooling zones:

-

1

-

Maximum width of PCB:

-

300mm

-

Normal Power:

-

4Kw

-

Transporter belt height:

-

880±20mm

-

Transfer method:

-

Net drive

-

Conveyor belt speed:

-

0-2000mm/min

Product Description

SMT table reflow soldering

Quality assurance after-sales rest assured

Focus on R&D and production of SMT mounter and peripheral equipment.

Product advantage

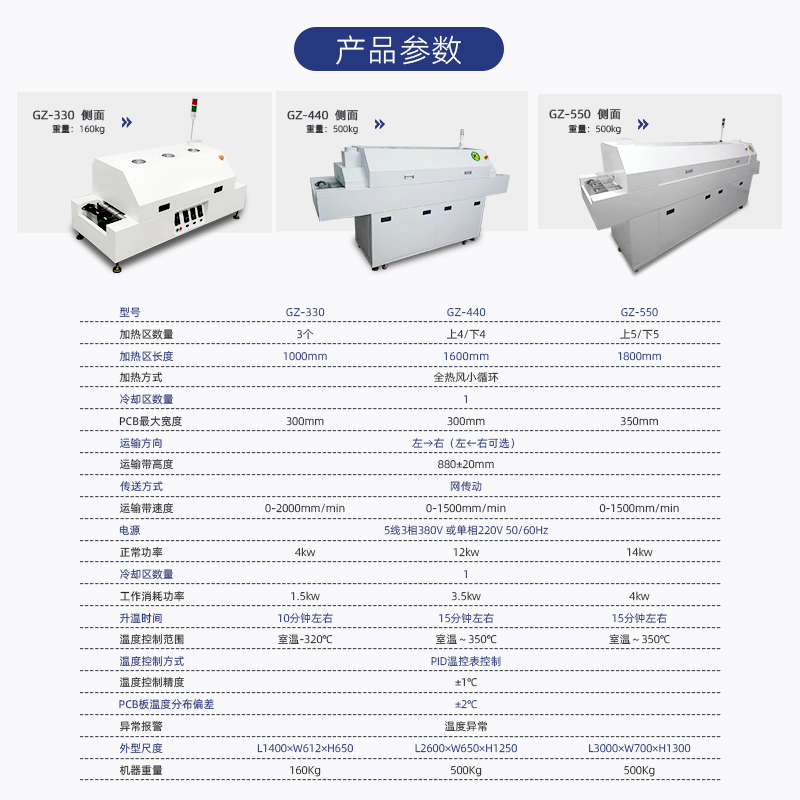

Product parameter

|

Model number

|

RF-330 (Three temperature zone)

|

RF-830LS (4-temperature zone)

|

RF-535LS (Five temperature zone)

|

||

|

Number of heating zones

|

3

|

Upper 4/ Lower 4

|

Upper 5/ Lower 5

|

||

|

Length of heating area

|

1000mm

|

1600MM

|

1800MM

|

||

|

Heating method

|

Full hot air small circulation

|

Full hot air small circulation

|

Full hot air small circulation

|

||

|

Number of cooling zones

|

1

|

1

|

1

|

||

|

Maximum width of PCB

|

300mm

|

300MM

|

350MM

|

||

|

Mode of transport

|

Left → Right (left ← Right optional)

|

Left → right (or right → left)

|

Left → right (or right → left)

|

||

|

Transporter belt height

|

880±20mm

|

880±20mm

|

880±20mm

|

||

|

Transfer method

|

Net drive

|

Net drive

|

Net drive + chain drive/net drive

|

||

|

Conveyor belt speed

|

0-2000mm/min

|

0-1500mm/min

|

0-1500mm/min

|

||

|

Power supply

|

5-wire 3-phase 380V or single-phase 220V 50/60Hz

|

5-wire 3-phase 380V 50/60Hz or single-phase 220V

|

5-wire 3-phase 380V 50/60Hz or single-phase 220V

|

||

|

Normal Power

|

4Kw

|

12kw

|

14kw

|

||

|

Power consumed at work

|

1.5 Kw

|

3.5 KW

|

4KW

|

||

|

Heating time

|

About 10 minutes

|

About 15 minutes

|

About 15 minutes

|

||

|

Temperature control range

|

Room temperature -320C

|

Room temperature ~ 350 ° C

|

Room temperature ~ 350 ° C

|

||

|

Temperature control mode

|

PID thermostat control

|

PID temperature control meter

|

Temperature control meter control

|

||

|

Temperature control accuracy

|

+ / - 1 ℃

|

+ / - 1 ℃

|

+ / - 1 ℃

|

||

|

PCB temperature distribution deviation

|

+ / - 2 ℃

|

+ / - 2 ℃

|

+ / - 2 ℃

|

||

|

Abnormal alarm

|

Abnormal temperature (too high or too low after constant temperature)

|

Abnormal temperature

|

Abnormal temperature

|

||

|

Shape scale

|

L1400×W612×H650mm

|

L2600×W650×H1250mm

|

L3000 * W700 * H1300mm

|

||

|

Weight

|

Approx160Kg

|

500KG

|

500KG

|

||

Product configuration

Every place is carefully built.

Precision work details/seals show quality

Double-layer toothed shaft transmission to prevent the circuit board from shifting, stainless steel B-shaped mesh belt, 300mm wide, equipped with locking system to ensure lasting deformation. Galvanized drum, speed regulating motor, can display the online running speed of equipment, 0:150 tooth box, and the speed can be adjusted at will from 0 to 0-2000/min.

The special high-temperature resistant motor of SCROCO, unique fan blade and heat dissipation design make the temperature and heat dissipation of the furnace balanced.

The temperature control range is from room temperature to -400℃ and the precision is 1℃, and the unique "power saving mode" can greatly save the production cost.

Formosa plastic two-color lamp, over-temperature red alarm. Alarm protection function, independent temperature zone protection device When the temperature is too high or too low, the alarm signal lamp will be sent to the intelligent thermostat, so that it can automatically adjust the temperature.

Hot Searches