- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4000*3000*3500

-

Year:

-

2024

-

Power (kW):

-

13.5 kW

-

Weight (KG):

-

900 KG

-

Belt Width:

-

Less than 1000mm

-

Working Pressure:

-

1.5 Mpa

-

Curing Temperature:

-

145℃

-

Heating Time:

-

15-20 minutes

-

Net Weight:

-

900kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

380V, 380v

-

Dimension(L*W*H):

-

4000*3000*3500

-

Year:

-

2024

-

Power (kW):

-

13.5 kW

-

Weight (KG):

-

900 KG

-

Belt Width:

-

Less than 1000mm

-

Working Pressure:

-

1.5 Mpa

-

Curing Temperature:

-

145℃

-

Heating Time:

-

15-20 minutes

-

Net Weight:

-

900kg

Products Description

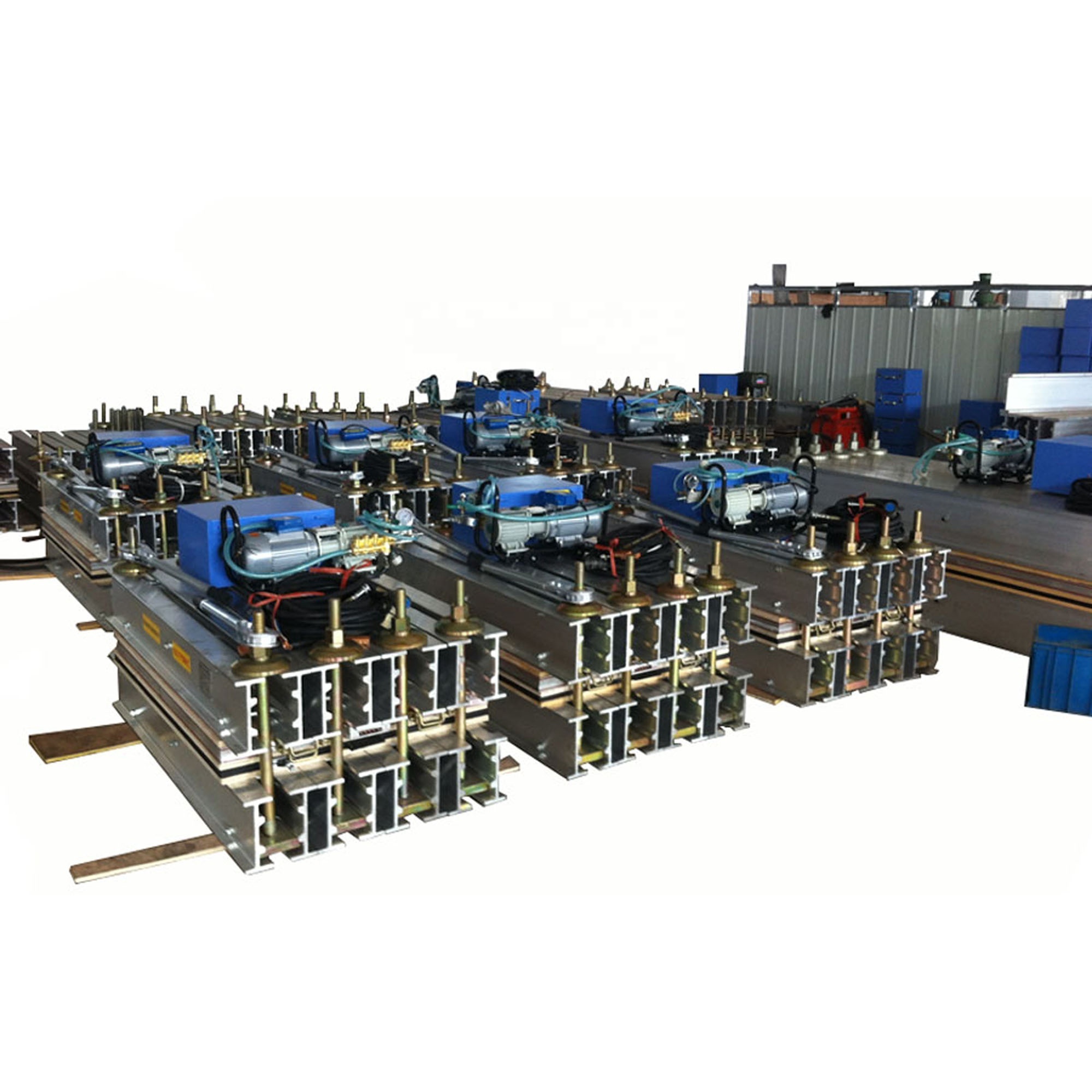

Equipment introduction

The electric heating vulcanization machine can be applied to the transport joints of the adhesive conveyors in metallurgy, chemical industry, metal mines, power plants, ports, wharfs, etc. The technical parameters provided by the machine and the execution of the correct vulcanization tape relay strength of more than 90%, not only the joint is smooth, almost the same as the original belt, but also can reduce the wear of the roller and extend the service life of the conveyor and rubber transport belt, our company can also customize various types of hot joint vulcanization machine according to customer needs, welcome to consult.

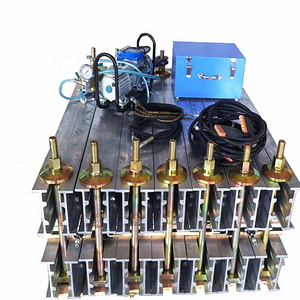

Product Feature

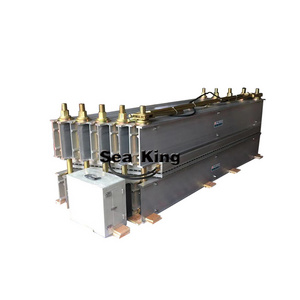

1. The rubber vulcanizing machine has light weight; About one person can move it. It consists of the following components: Rack / Pressure Bracket, fastening device,

sizing block, screw, nut, gasket, high-pressure hose, hydraulic test pump, thermal baffle, on the heating plate, secondary cable, electric cabinet, cables, down the heating plate, Suppress water bag.

2. The material of main machine components made of aluminum alloy, light weight, easy installation and removal, easy to handle.

sizing block, screw, nut, gasket, high-pressure hose, hydraulic test pump, thermal baffle, on the heating plate, secondary cable, electric cabinet, cables, down the heating plate, Suppress water bag.

2. The material of main machine components made of aluminum alloy, light weight, easy installation and removal, easy to handle.

3. Suppress water bag(its function is increase pressure) technology has reached international advanced level, it has following characters:

(1)Light weight, it is the 1/4 weight of the ordinary.

(2)Large expansion amplitude.

(3)Uniform pressure and the pressure can reach 3.0MPa.

(4)No water leakage and long life.

4. The electric cabinet can automatic rise temperature, automatic control temperature and calculate time.

(1)Light weight, it is the 1/4 weight of the ordinary.

(2)Large expansion amplitude.

(3)Uniform pressure and the pressure can reach 3.0MPa.

(4)No water leakage and long life.

4. The electric cabinet can automatic rise temperature, automatic control temperature and calculate time.

Product Paramenters

|

No. |

SPEC

|

Rating Voltage (V)

|

Power Frequency (HZ)

|

Motor Power (KW)

|

Applied Belt Width (mm)

|

|

1

|

ZLJ-650

|

380V/660V

|

50HZ

|

8.7

|

650

|

|

2

|

ZLJ-800

|

380V/660V

|

50HZ

|

10.6

|

800

|

|

3

|

ZLJ-1000

|

380V/660V

|

50HZ

|

13.5

|

1000

|

|

4

|

ZLJ-1200

|

380V/660V

|

50HZ

|

15.4

|

1200

|

|

5

|

ZLJ-1400

|

380V/660V

|

50HZ

|

18.2

|

1400

|

|

6

|

ZLJ-1600

|

380V/660V

|

50HZ

|

20.1

|

1600

|

|

7

|

ZLJ-1800

|

380V/660V

|

50HZ

|

22.1

|

1800

|

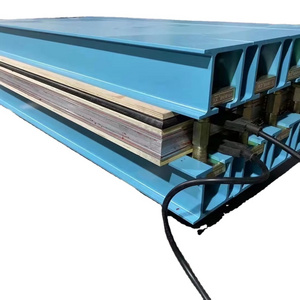

Product packaging

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden

packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and

then packed in wooden cases.

packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and

then packed in wooden cases.

FAQ

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production

manufacturers.If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Jiaodong airport. We will pick up you at

the airport.

Before leaving factory, this plate vulcanizing press needs to pass 24 hours' pressure test, pressure maintaining to test the

bearing of the hydro-cylinder and piston stroke and guarantee no oil leakage and seeping to avoid unnecessary quality problems.

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is

innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production

manufacturers.If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao Jiaodong airport. We will pick up you at

the airport.

Before leaving factory, this plate vulcanizing press needs to pass 24 hours' pressure test, pressure maintaining to test the

bearing of the hydro-cylinder and piston stroke and guarantee no oil leakage and seeping to avoid unnecessary quality problems.

Our Services And Certifications

♦ Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

♦ In the process of production, we will take photos and send to customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

♦ In the process of production, we will take photos and send to customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

Hot Searches