- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HIWOC

-

Voltage:

-

380 V 50Hz 3 phase

-

Power:

-

30kw

-

Dimension(L*W*H):

-

19450*3000*3100 mm

-

Weight:

-

4600 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

automatic hollow glass producing machine

-

Power supply:

-

380V/220V/Customer Specification

-

Total Power:

-

30kw

-

Max.glass size:

-

2500*3000mm

-

Glass thickness:

-

48mm

-

Min.glass.size:

-

400*450mm

-

Washing and drying speed:

-

0-8m/min

-

Transmission glass speed:

-

45m/min

-

Flow volume:

-

0.8m3/min

Quick Details

-

Machine Type:

-

Insulating Glass Production Line

-

Glass Thickness:

-

48mm

-

Production Capacity:

-

100%, 700-800Pcs/8h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HIWOC

-

Voltage:

-

380 V 50Hz 3 phase

-

Power:

-

30kw

-

Dimension(L*W*H):

-

19450*3000*3100 mm

-

Weight:

-

4600 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

automatic hollow glass producing machine

-

Power supply:

-

380V/220V/Customer Specification

-

Total Power:

-

30kw

-

Max.glass size:

-

2500*3000mm

-

Glass thickness:

-

48mm

-

Min.glass.size:

-

400*450mm

-

Washing and drying speed:

-

0-8m/min

-

Transmission glass speed:

-

45m/min

-

Flow volume:

-

0.8m3/min

Product Description

automatic hollow glass producing machine insulating glass production line

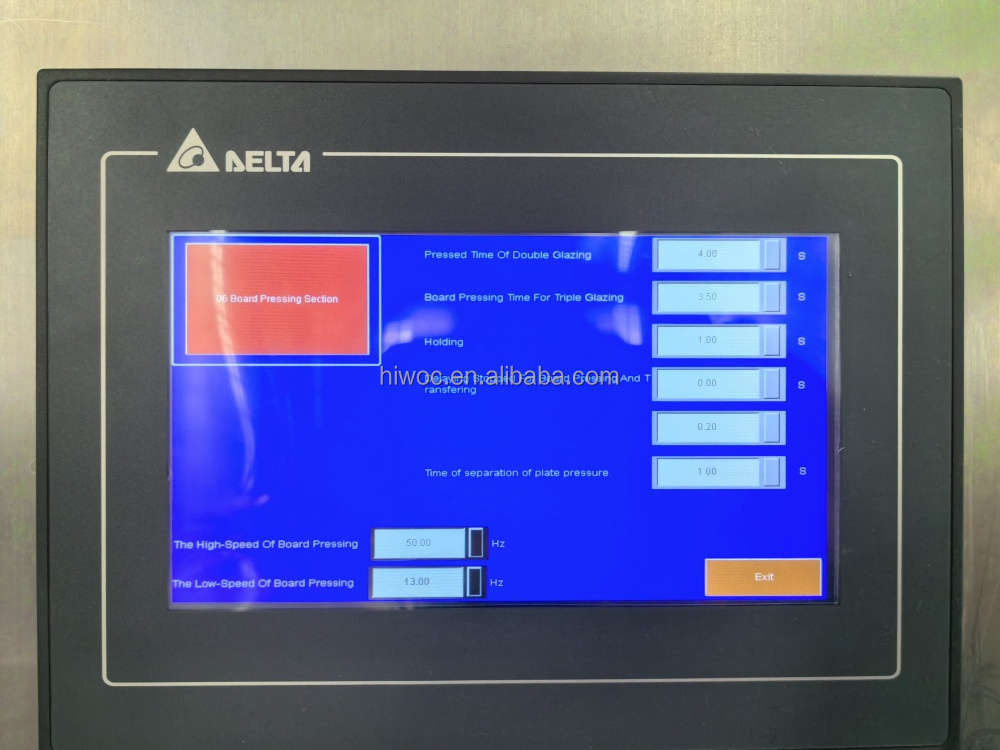

The coating and Low-E automatic distinguish system is installed on the input section before washing. When coating side is incorrectly put inside, the glass convey will be automatically stop. On washing section, inverter control of brush for Low-E glass, oil-less bearing, separate cabinet and water tank for two steps of washing and mist separating system are applied. Advanced static electricity releasing system is set at exit of washing section (option).

The first glass after washing-drying and inspecting stop at the assembly machine and position precisely by X-Y axis. Put spacer frame manually and then the glass stay at assembly section, which will be move backward after the glass arrive at position. At the same time the second glass after washing-drying are waiting at the assembly machine for positioning by guide bar. The panel reset and two pieces of glass are assembled and go to press. When processing triple glass, the assembly section goes backward again to let The third glass come in. The roller pushes 3 pieces of glass together and convey the IG units to press machine for pressing.After pressing, the IG unit is finished with the first seal and will be conveyed to the next section for second sealing.

The whole glass movement (stop or convey) is automatically controlled by the PLC system to reach a high productivity and flexible control of the production procedure.

Details

Specification

|

Machine Type

|

LBZ-2000P

|

LBZ-2500P

|

|

|

Production Capacity

|

100%

|

100%

|

|

|

Place of Origin

|

CHINA

|

China

|

|

|

Power

|

30 kw

|

45kw

|

|

|

Warranty

|

2 years

|

2 years

|

|

|

Glass Thickness

|

12-40 mm

|

12-40 mm

|

|

|

Core Components

|

PLC Pump

|

PLC, Pump

|

|

|

Power supply

|

380V or according to customer need

|

380V/220V/Customer Specification

|

|

|

Total Power

|

30 KW

|

45 KW

|

|

|

Max.glass size

|

2000*2500mm

|

2500*3000mm

|

|

|

Min.glass.size

|

300*500 mm

|

300*500 mm

|

|

|

Production Capacity

|

700-800Pcs/8h

|

|

|

|

Washing and drying speed

|

0-8m/min

|

|

|

|

Transmission glass speed

|

45 m/min

|

45m/min

|

|

Packing & Delivery

Hot Searches