- Product Details

- {{item.text}}

Quick Details

-

Use:

-

repair different motherboard

-

Weight (KG):

-

60 KG

-

After-sales Service Provided:

-

Online support

-

Power supply:

-

AC 110V/220V±10V

-

Business type:

-

Professional manufacturer

-

Heating way:

-

top/bottom hot air, infrared heating plate

-

PCB size:

-

410*380mm

-

Chip magnification:

-

2-50x

-

Temperature accurancy:

-

±1 ℃

-

PCB size::

-

450*430mm,10*10mm

-

Applicable PCB thickness:

-

0.3-5mm

-

Mounting accuracy:

-

± 0.01mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WDS motherboard repair machine

-

Dimensions:

-

880*880*720mm

-

Use:

-

repair different motherboard

-

Weight (KG):

-

60 KG

-

After-sales Service Provided:

-

Online support

-

Power supply:

-

AC 110V/220V±10V

-

Business type:

-

Professional manufacturer

-

Heating way:

-

top/bottom hot air, infrared heating plate

-

PCB size:

-

410*380mm

-

Chip magnification:

-

2-50x

-

Temperature accurancy:

-

±1 ℃

-

PCB size::

-

450*430mm,10*10mm

-

Applicable PCB thickness:

-

0.3-5mm

-

Mounting accuracy:

-

± 0.01mm

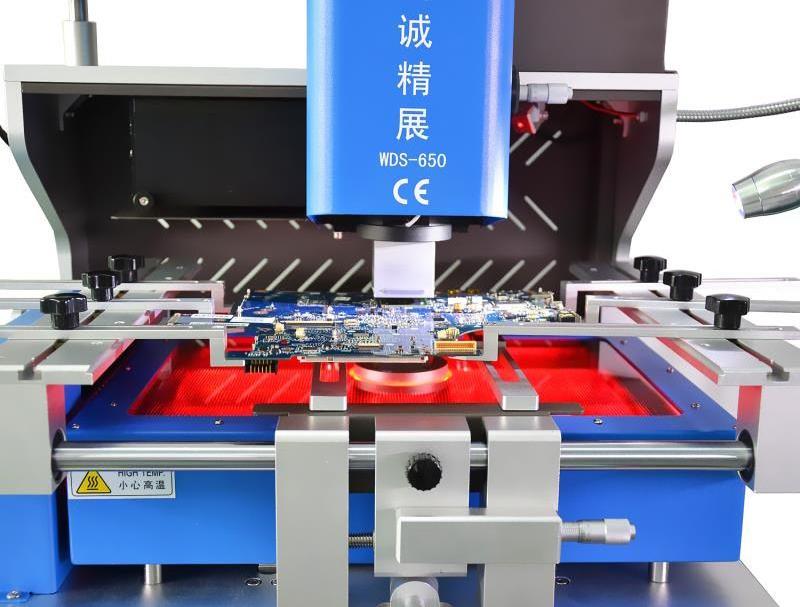

WDS-650 automatic BGA rework station mobile phone laptop motherboard repair machine

♥ Welcome to Wisdomshow shop,pls enjoy your shopping time ^.^ !

1. Smart phone /iPhone/iPad repair;

2. Notebook/ Laptop /Computer/Macbook /PC repair;

3. XBOX 360/PS2/ PS3/PS4 Wii and so on video game consoles repair;

4. Othe LED/SMD/SMT/IC BGA rework;

5. BGA VGA CPU GPU soldering desoldering;

6.BGA chips,QFP QFN chip,PC,PLCC PSP PSY rework.

4.Top heating head and mounting head 2 in 1 design.

5.Mounting head with built-in pressure testing device, to protect the PCB from being crushed.

6.Build-in vacuum in mounting head pick up BGA chip automatically after desoldering completed.

What is the parameter of WDS-650 auto bga rework machine?

| 1 |

Power supply |

AC 110V/220V±10% 50/60Hz |

| 2 |

Total power |

Max 6400W |

| 3 |

Heater power |

Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 4000W |

| 4 |

Locating way |

V shape slot,PCB support jigs can adjust, laser light do fast centering and position |

| 5 |

Temperature controlling |

(high precision K-sensor)(Closed Loop),independent temp.controller, the precision can reach ±1℃ |

| 6 |

Electrical material |

Driving motor+ smart temp.controller+color touch screen |

| 7 |

PCB size |

Max 410×380mm Min 10×10 mm |

| 8 |

Applicable chips |

Max 70×70mm Min 1×1 mm |

| 9 |

Applicable PCB thickness |

0.3-5mm |

| 10 |

Alignment system |

Optical lens + HD industrial camera |

| 11 |

Mounting accuracy |

±0.01mm |

| 12 |

Temperature Interface |

3 pcs |

| 13 |

Tin spot monitoring |

Optional external camera to monitor solder ball melting process during welding |

| 14 |

Camera in and out |

Auto out & in |

| 15 |

Overall dimension |

L600×W640×H850mm |

| 16 | Other function | 5 working modes . Auto/ manual mode switch freely |

| 17 |

Weight of machine |

60kg |

What is the specification of WDS-650 auto bga rework machine?

Independent 3 heating zones temperature control system

1.The upper and lower hot air heating, IR preheating zone adopts imported infrared gold-plated light tube to heat up quickly,which can heat up at the same time from the top of he component to the bottom of the PCB, to make the PCB board heated averagely,ensure welding effect;bottom IR heating,temperature precision control within ±1℃.8 segment temperature control independently.Infrared gold-plated light tube control heating independently.LED module repair machine

2.Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and combine freely the energy of up and lower heating element.

3.Adopted high precision K-type thermocouple close-loop control and PID parameter self-setting system;

4 temperature curves can be displayed with instant curve analysis function and multi-group user data can be saved;temperature can be tested precisely through external measurement interface,curves can be analysed,set and correct on the touch screen at any time.

1.Automatically pick up and replace chips;

2.Built-in pressure testing device,can detect pressure of 0.8g.While the testing device detect the pressure,the machine head will stop falling automatically to protect PCB from being crushed;

3.Different sizes of vacuum sucker work for different sizes of chip.

High temperature resistance ceramic glass

1.Prevent IC chip from being dropped and burnt

2.Infrared heating is more easily absorbed by PCB

3.More effectively prevent PCB from defomation,make heating more evenly

Sensitive MCGS touch screen

1.Multi storage 5000+ temperature profiles for different chip;

2.Display set and practical temperature;

3.English,Spanish,French and other languages are available.

Precision optical alignment system

1.Color optical system with functions of split vision, two color separation, zoom in/out and micro-adjust, equipped with aberration detection device, with auto focus and software operation.

2.CCD camera amplify up to 200x, with top/down light brightness adjust function, mounting accuracy is within 0.01 mm,and equipped with 15” high definition LCD monitor.

♦ HD digital display

Effectively show condition of alignment of welding spot and IC chip

♦ Precise CCD optical alignment system

1.8 million pixels

2.Mounting accurancy within 0.01mm

Multi-functional and humanized operation system

1.Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in 1;providing many kinds of titanium alloy BGA tuyere can be rotated in 360 degree for easy installation and replacement.

2.X,Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of temperature abuse, the circuit can power off automatically with the double over-temperature protection.Temperature parameter having password protection to prevent any modification.LED module repair machine

♦ Second heating zone height adjust

Distance between PCB and nozzles can be adjusted withi this rotary handel,suitable distance is 2-3mm

♦ Heating zone adjust swtich

Can switch off the heating plate on both sides if the motherboard is small

♦ Laser position

Location the chip fast

♦HD camera contrl

Controlled by motor to in/out

♦ Micrometer

1.Slightly adjust angel of chip for precise alignment

2.Mounting accuracy within 0.01mm

3.Effectively increase success rate of repairing

♦ K-sensor

Test the temperature to get the accurate heating profile

1,Standard export wooden package for bga rework station: 70*81*90cm,105KG;

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX, EMS or by air ;

4,Loading port: Shenzhen or Hongkong.