- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.5*1.2*1.4m

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Weight (KG):

-

400

-

Product name:

-

carbonization stove

-

Raw material:

-

wood

-

Name:

-

carbonization stove

-

Keywords:

-

carbonization stove

-

Usage:

-

Making wood Charcoal

-

Advantage:

-

Energy Saving

-

Final product:

-

Making wood Charcoal

-

Application:

-

Making wood Charcoal

-

Capacity:

-

1-5t

-

Color:

-

Customers Requirement

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KUNTENG

-

Effective Volume:

-

200

-

Dimension(L*W*H):

-

1.5*1.2*1.4m

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Weight (KG):

-

400

-

Product name:

-

carbonization stove

-

Raw material:

-

wood

-

Name:

-

carbonization stove

-

Keywords:

-

carbonization stove

-

Usage:

-

Making wood Charcoal

-

Advantage:

-

Energy Saving

-

Final product:

-

Making wood Charcoal

-

Application:

-

Making wood Charcoal

-

Capacity:

-

1-5t

-

Color:

-

Customers Requirement

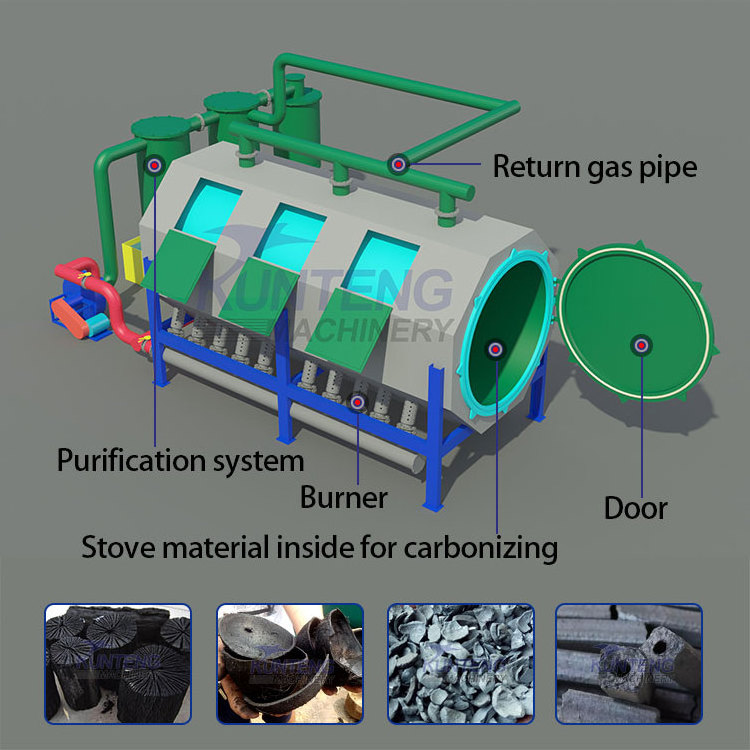

PRODUCT OVERVIEW

Carbonization Process: Feeding raw material and sealing the furnace→Preheating and drying the raw material → Anaerobic carbonization →Cooling and discharging the carbon.

DETAILS DISPLAY

CARBONIZATION STOVE

Carbonization stove,

burning coal in log burner and carbonizing machine

are made by horizontal manufacturing process, in which there is a three-layer structure with polyurethane insulation material in the middle to keep the temperature inside the furnace. The door of the furnace is sealed with filler, which does not enter the air, and the carbon output is much higher than that of the conventional charring furnace. It is called green carbonization furnace because the carbonizing process produces a lot

of yellowish combustible gases from the sticks. These gases pass through the charring furnace with its own pipeline, which allows the combustible gases to be transferred to the charring furnace combustion area for secondary fire heating. It is more environmentally friendly and saves fuel. Excess gas from the charring furnace can be used to dry sawdust or to fire the boiler.

The cooling time of the charring furnace is shorter, we use the gap between the intermediate layers to naturally cool the carbonization

furnace with unit water cooling, which is more efficient and convenient.

Carbonization stove, burning coal in log burner and carbonizing machine

can use different material as heating source.Such as the waste wood, coal, gas, natural gas, liquefied gas, combustible gas(produced during the carbonized process)

Peanut shell, Palm shell, Wood log, Coconut shell, sawdust, bamboo or other biomass can be carbonized into peanut shell, palm shell charcoal, coconut shell charcoal, bamboo charcoal, sawdust charcoal, biomass charcoal by carbonization equipment.

Raw materials of c

arbonization stove, burning coal in log burner and carbonizing machine

can be peanut shell, coconut shell, wood, biomass, some crops, bamboo, waste wood, branches, trunks, logs, bark, stumps, roots, wooden pallet, sawdust, shavings, wood chips, fruit wood, rice husk, corncob, peanut shell, furfural residue, palm shell, semi-coke and etc.

We could customize reasonable and efficient production line according to customers' site, raw materials, output and other requirements.

Firstly, palm shell, coconut shell, wood, bamboo and other biomass are carbonized into charcoal by carbonization furnace and enter hoister and storage tank. According to customer's raw material, you can choose continuous carbonization furnace, horizontal charcoal making stove and hoisting carbonization furnace.

Secondly, charcoal can be crushed into charcoal powder by dust-free grinder.

Thirdly, charcoal powder are stirred by double shaft mixer and mixer.

In the end, charcoal powder can be formed into ball, cylinder, tables and cubic by briquette machine and enter the dryer by

drying.

The whole c

arbonization stove, burning coal in log burner and carbonizing machine

production line are fully automatic.

Click the machines below for more details

PARAMETER

|

TYPE

|

SIZE

|

CAPACITY(kg)

|

GROSS WEIGHT(kg)

|

THICKNESS OF STEEL

|

|

KT1500-1000

|

1.5*φ1m

|

700

|

400

|

6mm

|

|

KT1500-1200

|

1.5*φ1.2m

|

850

|

500

|

6mm

|

CUSTOMER SITES

Carbonization stove customer sites

Our team have more than 20 years export experience for carbonization furnace production line. We can help optimize the drying process according to the property of different materials, production scale, application requirements, cost control, automation level and site condition.

PACKING & SHIPPING

The plastic film bag wrapped machine, according to the size and weight to make wood case, put machine in and fixed the box after loading. (The box material can be made as your requirements) The carbonization machine parts need to be put in a fixed container, should be fixed well, lest collision and wear, or lost.

COMPANY PROFILE

Henan KUNTENG Machinery Manufacture Co.,Ltd is specilize in producing briquette machine, there are many useless material in the world, our machine can make these material recycling use, and make high profit for user. Our equipment can make charcoal or briquette from waste material. Since our company's inception, has high credibility. And we help customers design the best quality

product line for different types machine. Our machine sold at home and abroad. We supply those certifications like CE ISO9001, CO,

Form E, COC, CIQ, to help customers from different countries clearance.

KUNTENG Group Service Items

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

FAQ

Q: What is your Business Model? Trading company or factory?

A:We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: KUNTENG Group products come with best quality, and our products passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

Q: How long is the Warranty of your equipment?

A: Our warranty period is one year generally.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

A:We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: KUNTENG Group products come with best quality, and our products passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

Q: How long is the Warranty of your equipment?

A: Our warranty period is one year generally.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

Plz feel free to contact us for details.

Hot Searches