- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DUOYUAN

-

Voltage:

-

110V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

8560 kg

-

Product name:

-

Production Line Car Body Jig Air Conditioner Assembly Line

-

Color:

-

Customized

-

Customers:

-

Yutong, KingLong, BYD, etc

-

Effect:

-

Body Frame Assembly

-

installation:

-

Yes, on site

-

Process:

-

Professional Product Lines

-

Product:

-

Automotive production line

-

Key Word:

-

automatic factory for buses

-

Conveyor type:

-

Automatic Conveyor Line

Quick Details

-

Power:

-

Customized

-

Warranty:

-

1 Year

-

Width or Diameter:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DUOYUAN

-

Voltage:

-

110V/380V

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

8560 kg

-

Product name:

-

Production Line Car Body Jig Air Conditioner Assembly Line

-

Color:

-

Customized

-

Customers:

-

Yutong, KingLong, BYD, etc

-

Effect:

-

Body Frame Assembly

-

installation:

-

Yes, on site

-

Process:

-

Professional Product Lines

-

Product:

-

Automotive production line

-

Key Word:

-

automatic factory for buses

-

Conveyor type:

-

Automatic Conveyor Line

Duoyuan automobile equipment, founded in March 1998, is a professional technology-based automotive equipment, welding fixtures, wire body conveying equipment, rolling equipment and a variety of related customized automation equipment development, design, manufacturing and service business.

In order to realize a better future, we, by upholding the spirit of exploration, learn widely from others' strong points and absorb foreign and domestic advanced experience, and strive for the development of China's automotive equipment!

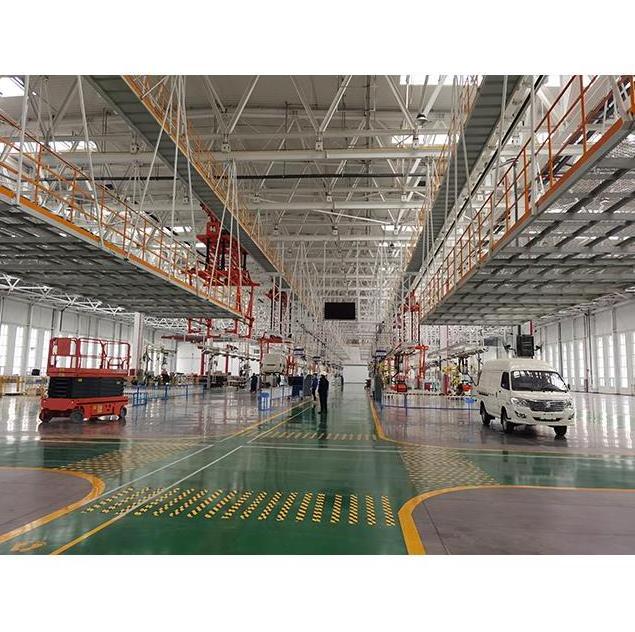

Light bus production line equipment for vehicle assembly plant

|

Product Name

|

Light bus production line equipment for vehicle assembly plant

|

|

Project Type

|

Turn-key engineering for bus production line

|

|

Automobile Equipment

|

bus assembly equipment, welding equipment, installation equipment, auto lift, rolling equipment and transportation equipment.

|

|

Conveyor Type

|

Automatic automotive conveyor system

|

|

Scope of Application

|

Car,,Bus,Truck, New Energy Automobile and other Vehicles assembly line

|

|

After-sales Service Provided

|

Engineers available to service machinery overseas

|

STAMPING PROCESS IN Light bus production line equipment for vehicle assembly plant

Stamping process in bus CKD SKD

BUS VEHICLE PRODUCTION ASSEMBLY LINE

is a common processing technology in automobile production, which is based on the plastic deformation of metal. Under normal temperature, the sheet metal is pressed by the die and stamping equipment to produce plastic deformation or separation, so as to obtain parts with certain shape, size and performance. It has been widely used in various fields.

WELDING LINE IN Light bus production line equipment for vehicle assembly plant

The assembly equipment in welding line is a large-scale equipment used for assembling standard bus body. It adopts the principle of exterior positioning to complete the hoisting, positioning, clamping, assembly and welding of six pieces of skeleton. It is the key equipment to realize the mechanization, batch and flow operation of bus body production. The use of this equipment can improve the stability of body quality, improve production efficiency and realize large-scale production.

PAINTING LINE IN Light bus production line equipment for vehicle assembly plant

Bus painting process in bus production line, generally can be divided into two parts: one is the metal surface treatment before coating, also known as pretreatment technology; The second is the coating construction technology. The surface treatment mainly includes the removal of oil, dust, rust on the surface of the workpiece, and the removal of the old coating layer during the repair operation, so as to improve the surface condition of the workpiece.