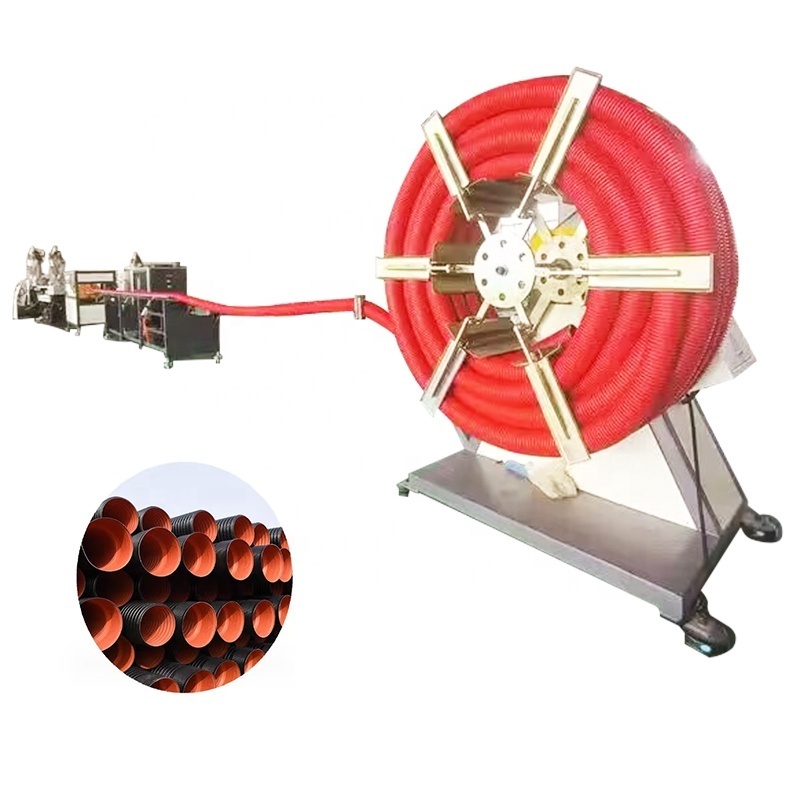

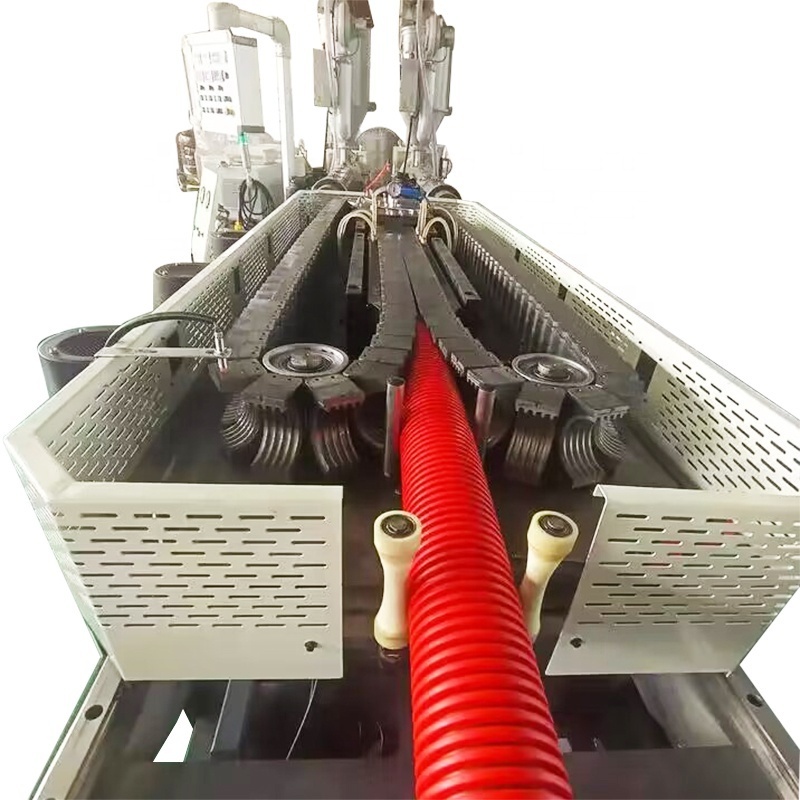

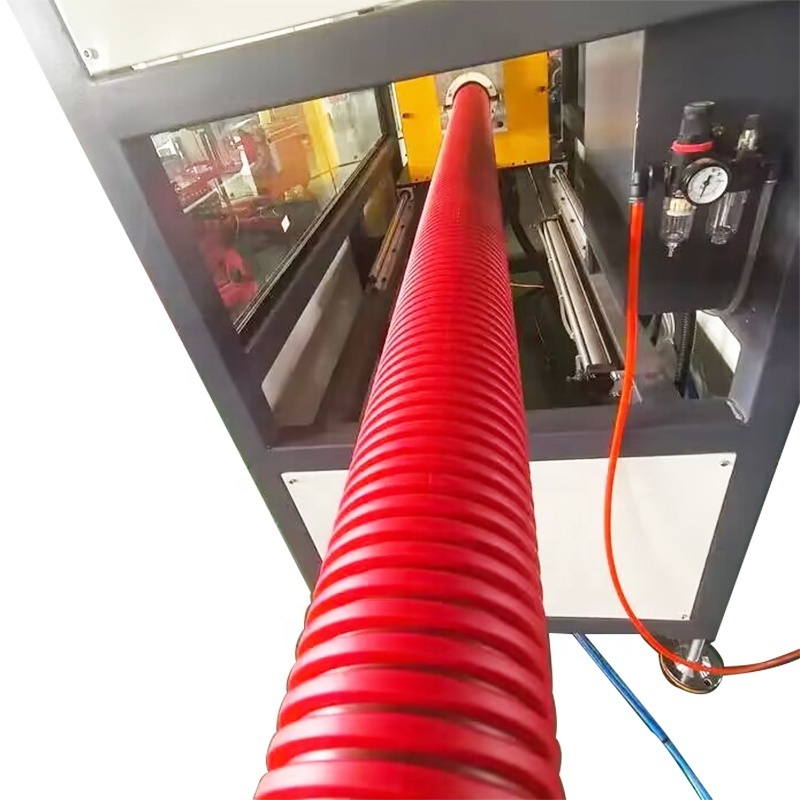

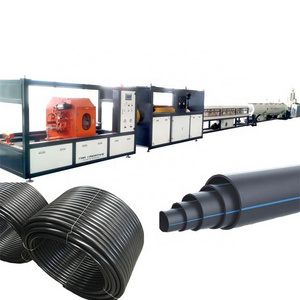

PE LDPE HDPE PP Corrugated Pipe Line Plastic Corrugated Pipe Manufacturing Machine Extrusion Line

Qingdao Zhongsu Machinery Co., Ltd. is a professional manufacturer of plastic pipe machine, located in Jiaozhou City, Qingdao, one of the concentrated areas of plastic machinery industry in China.

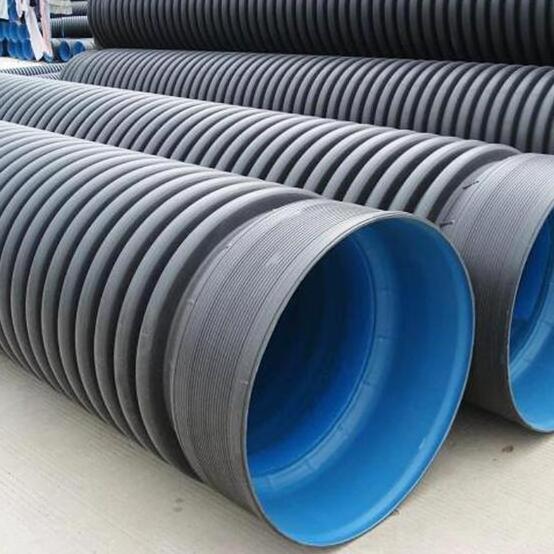

Main uses of plastic corrugated pipe: single-wall corrugated pipe are mainly used for machine tool machinery and cabinet control cabinet wiring connection, such as instrumentation, control cabinet, equipment manufacturing, engineering installation, train, automobile, subway, machine tool machinery, automation control and other industries. Double-wall corrugated pipe is mainly used for drainage pipe of municipal construction and mine seepage pipe.

Main uses of plastic corrugated pipe: single-wall corrugated pipe are mainly used for machine tool machinery and cabinet control cabinet wiring connection, such as instrumentation, control cabinet, equipment manufacturing, engineering installation, train, automobile, subway, machine tool machinery, automation control and other industries. Double-wall corrugated pipe is mainly used for drainage pipe of municipal construction and mine seepage pipe.