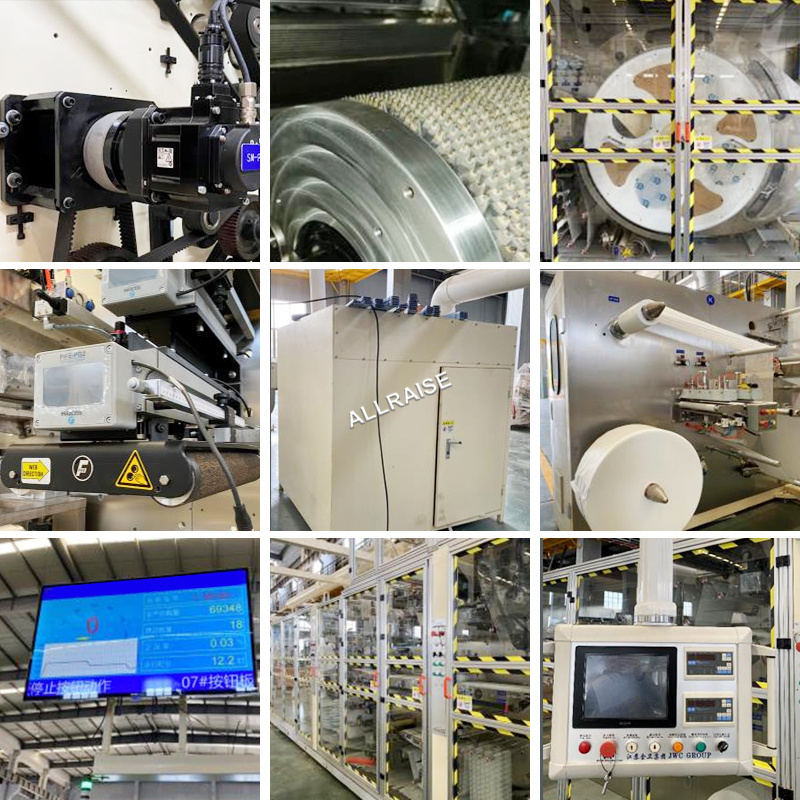

1)Reasonably solid square steel frame: Panel 25mm thick, adopt specular paint, 6 surfaces processing, solid cage with 60 * 60mm square steel in module design, the base frame with square tube 120mm*120mm, 18mm thick bottom plate, 4 surface processing also ,widening after gearbox for repair. Spliced type main board by screw, makes sure the

high efficiency.

2) Whole layout is main machine+ external unwinding machine unit+ back operating

platform, glue applicator on the back operating platform, cabinet put beneath.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

allraise

-

Voltage:

-

380V

-

Power:

-

390KW

-

Dimension(L*W*H):

-

25*2.1*4.8 M

-

Weight:

-

820000 kg

-

Marketing Type:

-

New Product 2023

-

Design speed:

-

600pcss/min

-

Qualified rate:

-

≥ 97%

-

Efficiency:

-

≥ 85%

-

Installation capacity:

-

~390KW (main machine +glue system+ stacker)

-

Running capacity::

-

~292.5KW

-

Electricity:

-

380V,50HZ (Accept customized)

-

Wire:

-

Three phases four wires 380V/50Hz (ground wire)

-

Air pressure:

-

6 kg/cm2 ≥0.8mpa

-

Total weight:

-

82tons

-

Machine size:

-

25*2.1*4.8 M

Quick Details

-

Production Capacity:

-

600pcss/min

-

Product Type:

-

baby diaper machine

-

Processing Type:

-

baby diaper machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

allraise

-

Voltage:

-

380V

-

Power:

-

390KW

-

Dimension(L*W*H):

-

25*2.1*4.8 M

-

Weight:

-

820000 kg

-

Marketing Type:

-

New Product 2023

-

Design speed:

-

600pcss/min

-

Qualified rate:

-

≥ 97%

-

Efficiency:

-

≥ 85%

-

Installation capacity:

-

~390KW (main machine +glue system+ stacker)

-

Running capacity::

-

~292.5KW

-

Electricity:

-

380V,50HZ (Accept customized)

-

Wire:

-

Three phases four wires 380V/50Hz (ground wire)

-

Air pressure:

-

6 kg/cm2 ≥0.8mpa

-

Total weight:

-

82tons

-

Machine size:

-

25*2.1*4.8 M

Products Description

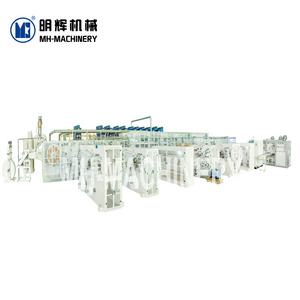

Baby Diaper Machine Baby Diaper Production Line Baby Diaper Making Machine

|

Design speed

|

600pcss/min

|

|

Qualified rate

|

≥ 97%

(exclude the wastage due to the glue applicators and materials splicing joint) |

|

Efficiency

|

≥ 85%

|

|

Installation capacity

|

~300 KW (main machine)

~390KW (main machine +glue system+ stacker) |

|

Running capacity:

|

225KW(main machine);

~292.5KW (main machine +glue system+ stacker) |

|

Electricity

|

380V、50HZ (Accept customized)

|

|

Wire

|

Three phases four wires 380V/50Hz (ground wire)

3X120mm³+1X70mm³+1X25mm³ |

|

Air pressure

|

6 kg/cm2 ≥0.8mpa

|

|

Total weight

|

82tons

|

|

Machine size

|

25×2.1×4.8 M(L×W×H)

|

|

Working space

|

33×10×5.5 M (L×W×H)

|

|

Product size

|

S、M、L、XL

|

|

Containers

|

5X40HQ

|

3) The main air suction bucket is installed with negative pressure display; the air scoop driven

wheel is installed with quick fixture to facilitate the removal of the belt; the lower side of the conveyor belt above the material is installed with support plate to prevent the polymer and foreign matters from falling and polluting the lower material (the belt

specification is labeled for maintenance) .

4) Equip with gantry crane, easy to change the shape cutter unit

5) The enter distance of all tool unit can be adjusted online by hand wheel

wheel is installed with quick fixture to facilitate the removal of the belt; the lower side of the conveyor belt above the material is installed with support plate to prevent the polymer and foreign matters from falling and polluting the lower material (the belt

specification is labeled for maintenance) .

4) Equip with gantry crane, easy to change the shape cutter unit

5) The enter distance of all tool unit can be adjusted online by hand wheel

Related Products

Contact us

Tel/Whats App/Wechat: +86 19937391241

Package&Shipping

|

Packaging

|

By container or standard export packing per machine

|

|

Delivery time

|

15-30 days after payment received

|

Hot Searches