- Product Details

- {{item.text}}

Quick Details

-

Hose Inner Diameter:

-

38 mm

-

Air Consumption:

-

6-7m3/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GAODETEC

-

Voltage:

-

customization

-

Power:

-

4kw

-

Dimension(L*W*H):

-

1600x1000x1300mm

-

Weight:

-

665 kg

-

type:

-

refractory shotcrete gunning machine

-

output:

-

1.5-3m3/h

-

operation air pressure:

-

0.2-0.4Mpa

-

market:

-

global

-

rotor volume:

-

6.3L

-

water pump output:

-

26L/min

-

Rotor Speed:

-

4-8r/min

-

Material Charging Height:

-

1.1m

-

Water pump output:

-

26L/min

-

Automatic lubrication Volume:

-

2L

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Max. Conveying Distance:

-

200m

-

Max Aggregate Size:

-

10mm

-

Hose Inner Diameter:

-

38 mm

-

Air Consumption:

-

6-7m3/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GAODETEC

-

Voltage:

-

customization

-

Power:

-

4kw

-

Dimension(L*W*H):

-

1600x1000x1300mm

-

Weight:

-

665 kg

-

type:

-

refractory shotcrete gunning machine

-

output:

-

1.5-3m3/h

-

operation air pressure:

-

0.2-0.4Mpa

-

market:

-

global

-

rotor volume:

-

6.3L

-

water pump output:

-

26L/min

-

Rotor Speed:

-

4-8r/min

-

Material Charging Height:

-

1.1m

-

Water pump output:

-

26L/min

-

Automatic lubrication Volume:

-

2L

Products Description

Refractory gunning machine

1.

With this GZ-3ER/S refractory gunning machine, you can get low dust and high performance spraying flow in nozzle. Compared with our market popular GZ-3ER

refractory gunning machine

, This GZ-3ER/S is a new version.

2.

Automatically to clean delivery line blockage

; PLC+VFD+Air Pressure Sensor.

3.

Sector hole

to replace the circle hole in the rotor to improve the volume of the rotor and to decrease friction area, then with the same output, the rotor speed will be lower to improve the work life of rubber sealing plate and keep the motor power lower.

4.

The combination of gunning machine and

high pressure water pump

, it is easy to move.

5. A

dd

automatic lubricator

to the rubber seal plate to make the work life of wear parts longer and make the motor power lower.

Product parameters

|

GZ-3ER/S Refractory Gunning Machine

|

|

|

||

|

Rotor Volume

|

|

6.3L

|

||

|

Rotor Speed

|

|

4-8r/min

|

||

|

Max. Output

|

|

1.5-3m3/h

|

||

|

Max. Horizontal Conveying Distance

|

|

200m

|

||

|

Max. Aggregate Size

|

|

Φ10 mm

|

||

|

Conveying Hose Inner Diameter

|

|

38/ 32mm

|

||

|

Operating Air Pressure

|

|

0.2-0.4MPa (29-58PSI)

|

||

|

Air Consumption

|

|

6~7m3/min (215-250CFM)

|

||

|

Material Charging Height

|

|

1.1m

|

||

|

Rotor Motor

|

Power

|

4kW

|

||

|

|

Voltage

|

3 phase, 380V, 50Hz

|

||

|

Water Pump

|

Output

|

26L/min

|

||

|

|

Pumping Head

|

70m

|

||

|

|

Motor

|

1.5kw

|

||

|

Automatic lubrication

|

Volume

|

2L

|

||

|

|

Power

|

24V, 50w

|

||

|

Overall Dimension (L×W×H)

|

1600×1000×1300mm

|

1600×1000×1300mm

|

||

|

Weight

|

665kg

|

665kg

|

||

|

|

GZ-3ER

|

GZ-3AR

|

GZ-5ER

|

GZ-5AR

|

|||

|

Rated Output

|

1-3m3/h (2-6 tons/h)

|

|

1-5m3/h (2-10 tons/h)

|

1-5m3/h(2-10Ton/h)

|

|||

|

Max. Conveying Distance

|

200m

|

|

200m

|

100m

|

|||

|

Max. Aggregate Size

|

10mm

|

15mm

|

|

|

|||

|

Conveying Hose ID

|

38mm

|

51mm

|

|

|

|||

|

Operating Air Pressure

|

0.2-0.4MPa

|

|

|

|

|||

|

Air Consumption

|

5-6m3/min

|

10-11m3/min

|

8~9m3/min

|

15-16m3/min

|

|||

|

Drive Type

|

Electric

|

Air motor

|

Electric

|

Air motor

|

|||

|

Motor Power

|

4kw

|

/

|

5.5kw

|

/

|

|||

|

Rotor Speed

|

0-13.2r/min

|

|

|

0-13.2r/min

|

|||

Details Images

1. PLC integrated machine control/PLC.

2. Electric control cabinet cover.

3. Pneumatic master valve switch.

4.

Intelligent anti-clogging pipe system.

1. Integrated water pump installation.

2. Automatic lubrication pump.

1. Sector rigid liner.

2. Sector rotor body.

ABB variable frequency drive (VFD).

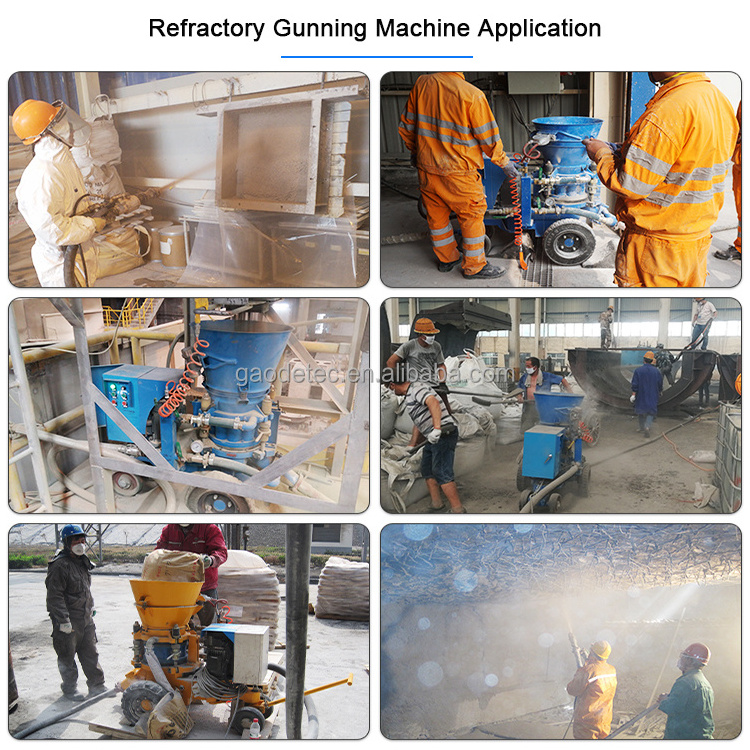

Application

Refractory gunning machine application

Our refractory gunning machine

is specially designed for spraying refractory materials, castable in refractory repair installing project. Such as

Aluminum Furnace Linings, Industrial Furnace Repair, Heat Treating Furnaces, Reheat Furnaces, Rotary Kiln Linings, Tunnel and Shuttle KiIns, Dryer and Combustion Chambers, Refractory Boiler Settings, Incinerator Rebuilds, Stack and Duct Linings, Ladle and Crucible Linings.

Related Product

Packaging&Shipping

Hot Searches