- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PZT

-

Usage times:

-

2 billion times

-

Usage time:

-

4 months

-

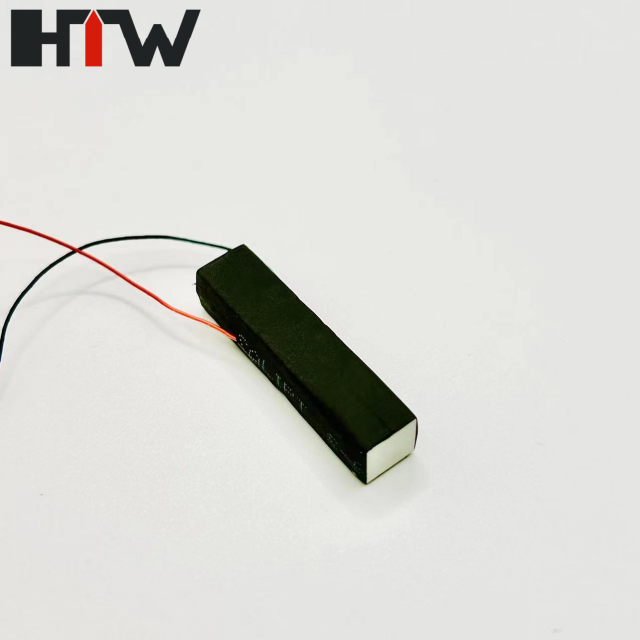

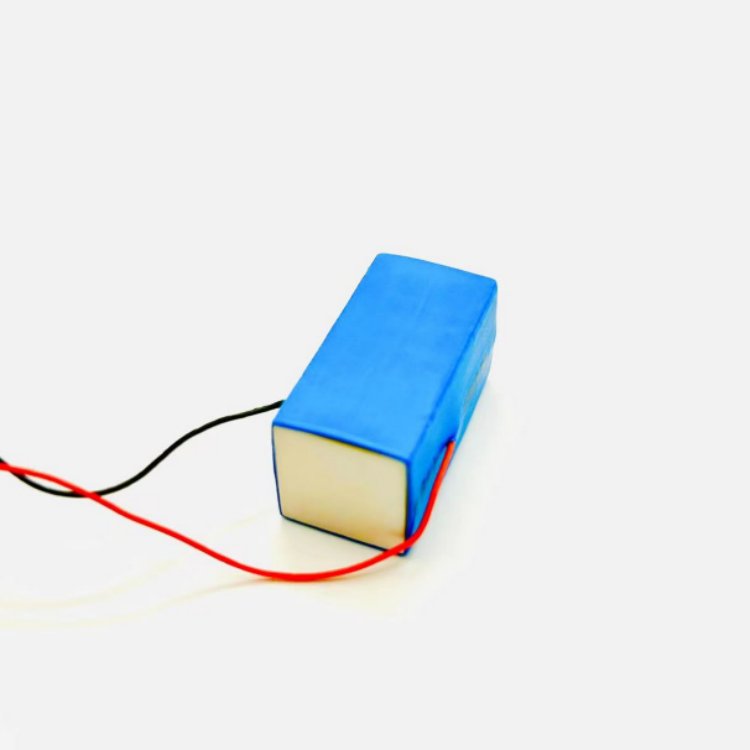

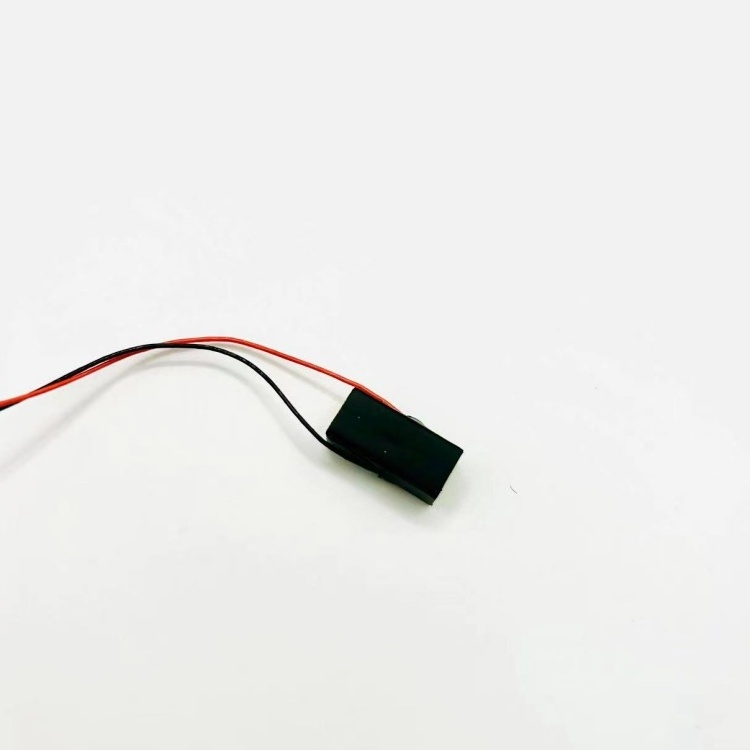

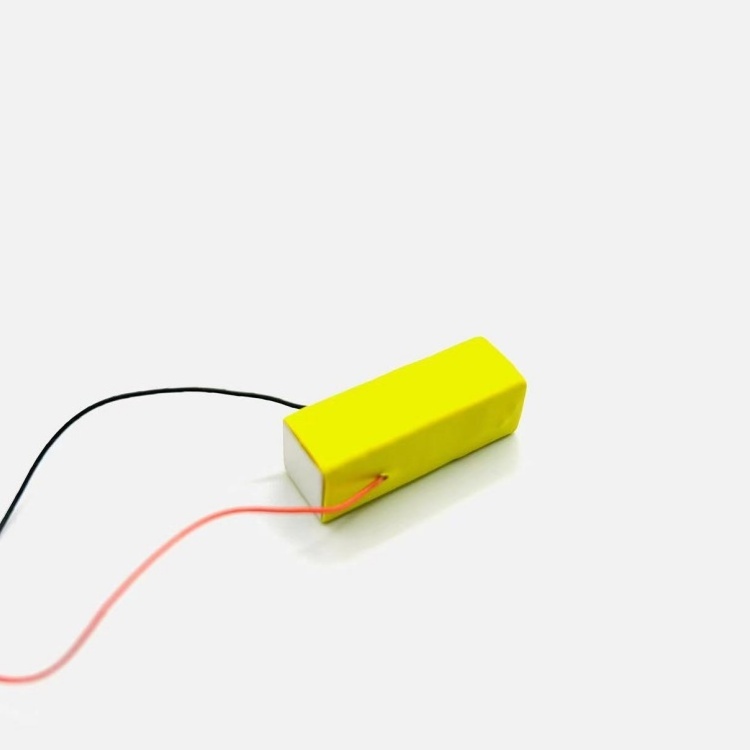

Encapsulation:

-

Epoxy + heat shrink tube

-

Voltage:

-

75V 120V 150V

-

Operating temperature:

-

-20--+80℃

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HTW

-

Model Number:

-

Piezo Actuators

-

Material:

-

PZT

-

Usage times:

-

2 billion times

-

Usage time:

-

4 months

-

Encapsulation:

-

Epoxy + heat shrink tube

-

Voltage:

-

75V 120V 150V

-

Operating temperature:

-

-20--+80℃

We began to develop large gauge coefficient piezoelectric ceramic materials in 2010. At the end of that year, it developed excellent products with piezoelectric constant d33 greater than 850×10-12m/V, dielectric constant 5500±10%, and dielectric loss less than 6%. Characteristics of piezoelectric ceramic materials. Through special process research, multiple specifications of piezoelectric ceramic stacked micro-actuators have been successfully produced using this series of materials.

Product Features

*High energy conversion efficiency

*High displacement accuracy (nanometer level)

*Large output force (up to 10000N)

*Fast response speed (sub-millisecond to microsecond)

*Low power consumption

*No electromagnetic interference

*Low sound of bath

*Small hysteresis

*Good return to zero reproducibility

*Good stability

*Relatively simple voltage control methods can be used, etc.

Application scope

*Various precision micro-motion stages

*Adaptive optics deformable mirror

*Fiber optic and laser tuning

*Optical microprocessing system

*Aircraft control

*Active vibration control

*Scanning Probe Microscope

*Ultra-precision machining, integrated circuit manufacturing

*Biomedical Engineering

*Fast response precision fuel nozzle

*Micro pumps, micro valves, etc.

Typical product specifications

For the other sizes, please contact our sales reps for more information.

|

Model |

Dimension (mm) |

Displacement

|

Blocking force

|

Stiffness

|

Capacitance

|

|

HT030305 |

3*3*10 |

10 |

300 |

30 |

0.3 |

|

HT030310 |

3*3*15 |

15 |

300 |

20 |

0.45 |

|

HT030320 |

3*3*20 |

20 |

300 |

15 |

0.6 |

|

HT050510 |

5×5×10 |

10 |

800 |

80 |

0.6 |

|

HT050520 |

5×5×20 |

20 |

900 |

50 |

1.1 |

|

HT050540 |

5×5×40 |

40 |

900 |

28 |

2.6 |

|

HT070710 |

7×7×10 |

10 |

1600 |

200 |

1 |

|

HT070720 |

7×7×20 |

20 |

1600 |

100 |

2.2 |

|

HT070740 |

7×7×40 |

38 |

1600 |

65 |

4 |

|

HT101010 |

10×10×10 |

10 |

3200 |

350 |

2 |

|

HT101020 |

10×10×20 |

20 |

3200 |

250 |

4 |

|

HT101030 |

10×10×30 |

30 |

3300 |

150 |

6 .0 |

|

HT101040 |

10×10×40 |

40 |

3300 |

100 |

9 .0 |

|

HT141410 |

14×14×10 |

10 |

7000 |

900 |

3.5 |

|

HT141420 |

14×14×20 |

20 |

7000 |

450 |

7 |

|

HT141430 |

14×14×30 |

30 |

7000 |

300 |

12 |

|

HT141440 |

14×14×40 |

40 |

7000 |

240 |

14 |

Remark:

1. The above products are all square simple insulating packages. According to user requirements, rectangular and ring-shaped devices of various sizes can be made; when users need it, they can also be packaged in metal shells.

2. The device specifications of the products in the table have a rated operating voltage of 150Vdc. Devices with other rated operating voltages can be designed according to user needs.

3. The overall dimensions in the specifications are those of the piezoelectric ceramic structure (excluding external encapsulation structure dimensions).