- Product Details

- {{item.text}}

Quick Details

-

Power:

-

46KW

-

Weight:

-

1900 KG

-

Dimension(L*W*H):

-

3.8x1x2m

-

Name:

-

Snack Puff Machine

-

Production Capacity:

-

180-250kg/h

-

Type:

-

Processing Line

-

Processing Types:

-

Screws Extrusion

-

Material:

-

304 Stainless Steel

-

Shape:

-

Clients' Demands

-

Feature:

-

High Efficiency

-

Advantage:

-

Easy Operation High Efficiency

-

Motor:

-

Siemens ABB

-

Inverter:

-

Delta Simens ABB

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KL

-

Voltage:

-

380V

-

Power:

-

46KW

-

Weight:

-

1900 KG

-

Dimension(L*W*H):

-

3.8x1x2m

-

Name:

-

Snack Puff Machine

-

Production Capacity:

-

180-250kg/h

-

Type:

-

Processing Line

-

Processing Types:

-

Screws Extrusion

-

Material:

-

304 Stainless Steel

-

Shape:

-

Clients' Demands

-

Feature:

-

High Efficiency

-

Advantage:

-

Easy Operation High Efficiency

-

Motor:

-

Siemens ABB

-

Inverter:

-

Delta Simens ABB

Product Description

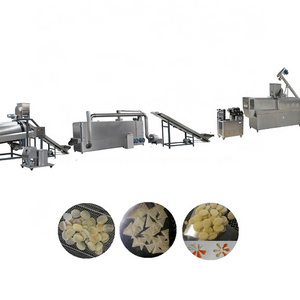

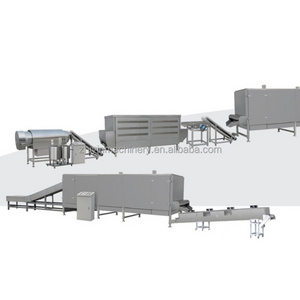

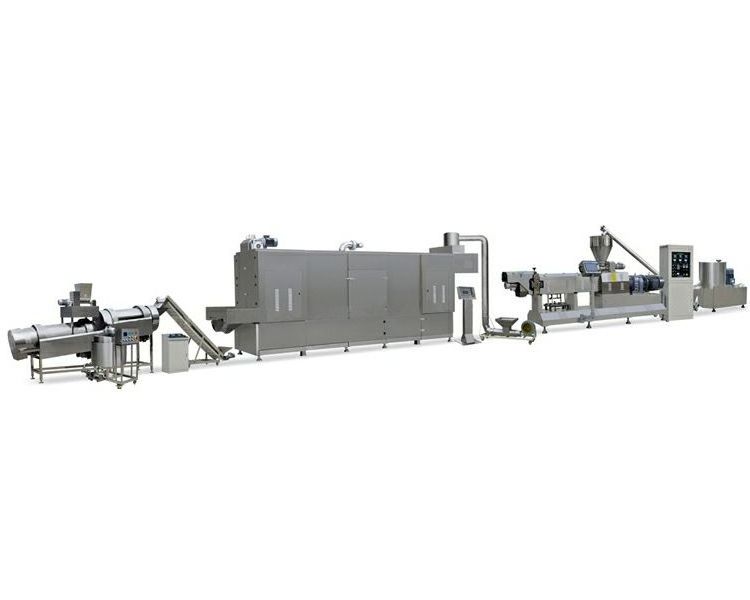

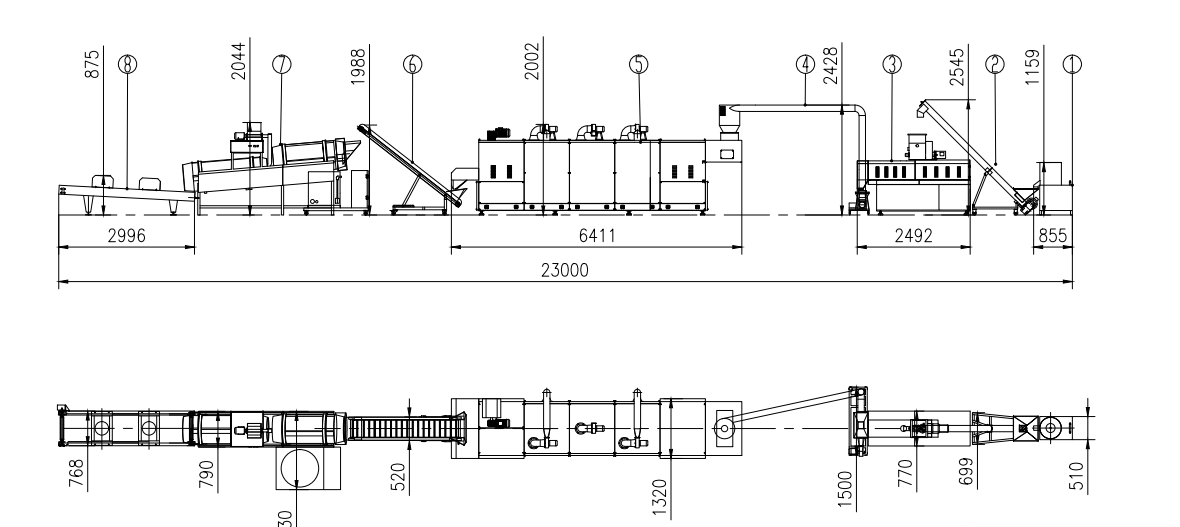

Automatic Industrial Puffed Corn Snack Machine Food Processing Machinery

|

NO.

|

Name

|

Brief introduction

|

|

1

|

Raw material

|

Corn, rice, wheat, oat, barley, millet, sorghum etc as main ingredients

|

|

2

|

Basic Recipe

|

Salt sugar powder, flavor material, cocoa powder and so on

|

|

3

|

Processing flow

|

Mixing system; Extrusion system; Drying system; Flavoring system; Packing System

|

|

4

|

Equipment involved

|

Mixer; Screw elevator; Double screw extruder; Air conveyor; Dryer; Flavoring system;Packing machine

|

|

5

|

Final products

|

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape cereal snacks by adjusting the mould in the extruder ;

|

|

6

|

Machine material

|

Stainless steel 304 or as customer’s request

|

|

Model

|

DZ-65

|

DZ-70

|

DZ-85

|

DZ-80

|

|

Voltage

|

220V/380V

|

220V/380V

|

220V/380V

|

220V/380V

|

|

Installed power

|

80kw

|

88kw

|

95kw

|

115kw

|

|

Power consumption

|

60kw

|

65kw

|

70kw

|

100kw

|

|

Capacity

|

120-150kgs/hr

|

180-250kgs/hr

|

300-500kgs/hr

|

500-800kgs/hr

|

|

Length

|

26m

|

28m

|

36m

|

45m

|

Product Sample

Detailed Images

|

Name

|

Mixer

|

|

Capacity

|

150kg/batch

|

|

Parameter

|

power: 7.5kw

|

|

Usage

|

Mixing various kinds of raw material

|

|

Working Principle

|

The motor drives the stirring cage, automatic water adding device and pneumatic discharge valve

|

|

Name

|

Screw conveyor

|

|

Capacity

|

According to the extruder

|

|

Parameter

|

power: 1.1/1.5kw

|

|

Usage

|

Conveying the raw material to Mixer.

|

|

Working Principle

|

The motor drives the screw in elevator, lifting the material from the low end to the high end.

|

|

Name

|

Doule Screw Extruder

|

|

Capacity

|

80-250kg/h

|

|

Parameter

|

According to different extruder

|

|

Usage

|

Raw material is curing and puffed in extruder, becoming different shapes of puffing snacks with moulds changing.

|

|

Working Principle

|

It consists of feeding system, extruding system, cutting system, heating system; main motor and controlling system.

|

|

Name

|

Dryer

|

|

Capacity

|

200-300kg/h

|

|

Parameter

|

power: 60kw

|

|

Usage

|

Drying puff corn snacks after extruding

|

|

Working Principle

|

The heating source can be electric, gas, steam and fuel. The material is stainless steel 304. It consists of rack system,

conmbustion system, dehumidifier system, sheet metal insulation system and controlling system. |

|

Name

|

Flavoring system

|

|

Capacity

|

200-300kg/h

|

|

Parameter

|

Power: 20kw

|

|

Usage

|

This device is applicable to a wide range of puffing corn snacks and fried snacks in seasoning and coating oil or sugar

|

|

Working Principle

|

Spraying nozzle can adjust oil amount equally. The sugar coating is built up by tumbler system.

The tumbler is derived by a motor, using for mixing and melting the water, sugar and other additives. |

After-sales Service

Engineering Support Team

Customer Service Team

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free online debugging of equipment until everything is functional;

4. Free management of equipment long distance shipping from seller's factory to place by the buyer;

5. Free training of equipment maintenance and operating personally in the seller's factory;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and life-time maintenance service; The seller is responsible for the nature damage of the machinery in one year except for man-made damage. All spare parts and wearing parts are attached with the machinery for free.

2. Free project planning and design services;

3. Free online debugging of equipment until everything is functional;

4. Free management of equipment long distance shipping from seller's factory to place by the buyer;

5. Free training of equipment maintenance and operating personally in the seller's factory;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and life-time maintenance service; The seller is responsible for the nature damage of the machinery in one year except for man-made damage. All spare parts and wearing parts are attached with the machinery for free.

About Us

1. Established in 1995, more than 24 years of experience in extrusion food machinery industry.

2. CE, ISO, SGS have been obtained, Our machine have been exported to 150 countries and districts.

3. We offer complete solution, turnkey solution service for customers.

4. Strong sales service team with 20 years of experience, ensuring high quality products.

5. Superior geographical position, the convenience traffic conditions. Located in Jinan city, Shandong province,1 hour away from Jinan airport, 2 hours away from Qingdao port.

4. Strong sales service team with 20 years of experience, ensuring high quality products.

5. Superior geographical position, the convenience traffic conditions. Located in Jinan city, Shandong province,1 hour away from Jinan airport, 2 hours away from Qingdao port.

How to Test Our Machine

1.We’ll offer machine working videos first.

2.We offer customized machine trial in our factory.

① If customers offer formulas, we’ll try our extruders in stock according to your formulas with our local purchased

materials. We’ll offer trial videos. We charge material cost, which will be refunded when you place order.

② If we couldn’t find the raw materials listed in your formulas, customers should offer raw materials.

③ If customer wants to check the trial samples, we’ll deliver samples by DHL, TNT, FedEx, etc. Customer will bear the

freight.

3. We also welcome you to visit our factory and we'll test machine specially to you, according to your requirments.

2.We offer customized machine trial in our factory.

① If customers offer formulas, we’ll try our extruders in stock according to your formulas with our local purchased

materials. We’ll offer trial videos. We charge material cost, which will be refunded when you place order.

② If we couldn’t find the raw materials listed in your formulas, customers should offer raw materials.

③ If customer wants to check the trial samples, we’ll deliver samples by DHL, TNT, FedEx, etc. Customer will bear the

freight.

3. We also welcome you to visit our factory and we'll test machine specially to you, according to your requirments.

Extruder Machine

Customized Production Lines

Hot Searches