- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

5000*800*1200mm

-

Weight:

-

3000 kg

-

Material thickness:

-

0.6-1.2mm

-

Producting speed:

-

300-700m/h

-

Size:

-

75*38mm, 89*41mm, 140*41mm ,etc

-

Roller station:

-

13 stations

-

Hydraulic cooling:

-

Fan cooling

-

Inkjet printer:

-

EC-JET

-

Materia of cutting:

-

Cr12Mov

-

Hydraulic pressure:

-

Computer set

-

Motor brand:

-

SIENEMS

-

Product name:

-

Light Gauge Steel Frame Lgs Machines For Prefabricated House

Quick Details

-

Marketing Type:

-

cheap price

-

Production Capacity:

-

8-15m/min

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

5000*800*1200mm

-

Weight:

-

3000 kg

-

Material thickness:

-

0.6-1.2mm

-

Producting speed:

-

300-700m/h

-

Size:

-

75*38mm, 89*41mm, 140*41mm ,etc

-

Roller station:

-

13 stations

-

Hydraulic cooling:

-

Fan cooling

-

Inkjet printer:

-

EC-JET

-

Materia of cutting:

-

Cr12Mov

-

Hydraulic pressure:

-

Computer set

-

Motor brand:

-

SIENEMS

-

Product name:

-

Light Gauge Steel Frame Lgs Machines For Prefabricated House

Specification

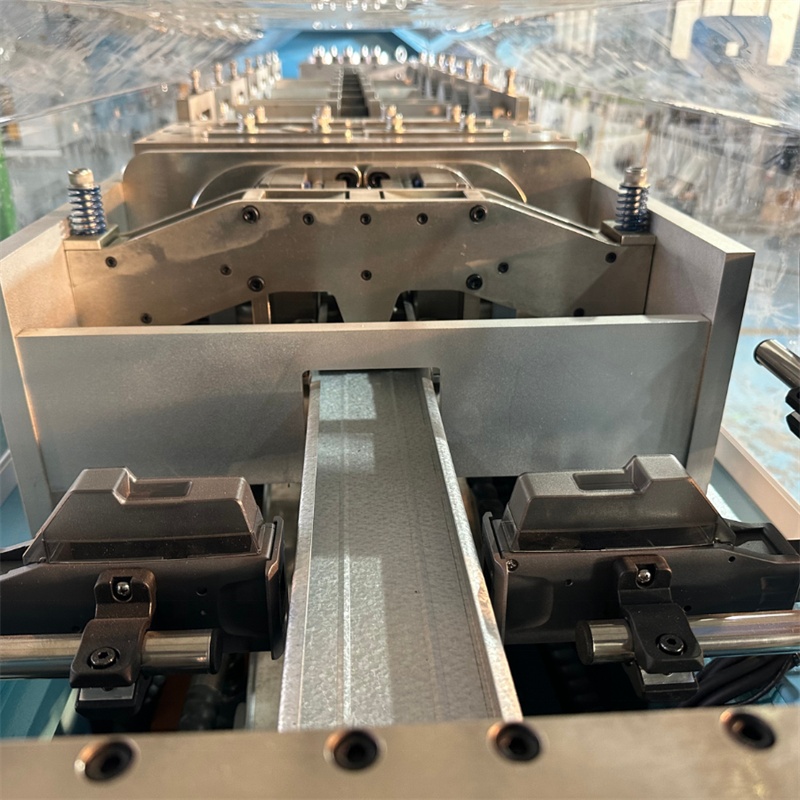

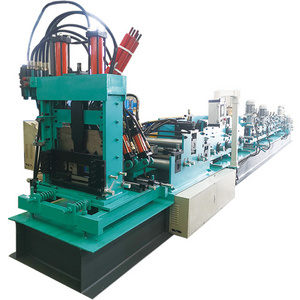

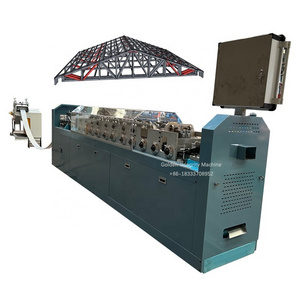

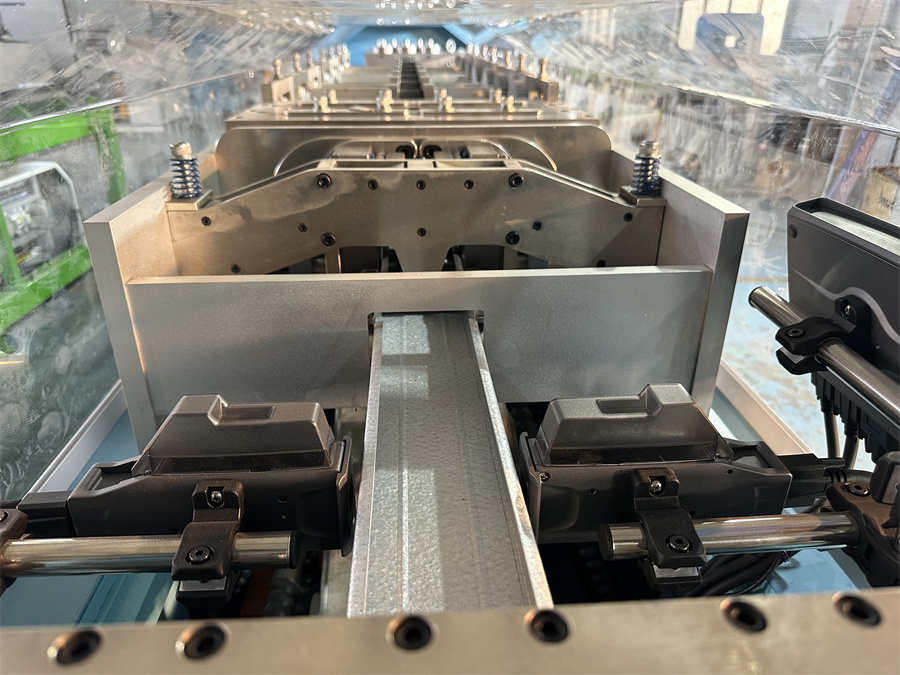

Steel frame structure vila house roll forming machine

The light steel frame machine is to make house steel frame, lighter mass, more efficient construction, safe and reliable structure, good seismic performance, improved thermal and acoustic insulation and indoor utilisation, and designed to offer increased production speed, greater flexibility and increased reliability, which is best suited for residential and light commercial projects. Producing profiles from 3.5" (89mm) to 6" (150mm) up to 18gauge (1.20mm) thickness.

C89 steel frame machine is suited to construct walls, floors and roofs for 1 – 3 level residential, modular and transportable units, and light commercial construction.

|

Main Specifications

|

|

|

|

Size

|

75*40*89*41, 140*41

|

|

|

Thickness

|

0.6-1.2mm(G300-G550Galvanzied coils and Aluzinc )

|

|

|

Feeding width

|

182mm coil strip

|

|

|

Max producing speed

|

1500m/h

|

|

|

Main motor

|

7.5KW

|

|

|

Hydraulic station

|

5.5kw

|

|

|

Hydraulic tank capacity

|

100L

|

|

|

Hydraulic cooling

|

Fan cooling

|

|

|

Hydraulic pressure

|

Manual set

|

|

|

Punching dies

|

Screw hole, chamfer, slot hole, flange cut, pipe hole, suspension, cutting

|

|

|

Inkjet printer

|

Imported brand

|

|

|

Machine size

|

4900*1000*1500mm

|

|

|

Power supplier

|

380V 50Hz 3phases or according to your request

|

|

|

Note:Our machine can be compatible with other design software like FRAMECAD, StrucSoft, ENDURO, etc.

|

|

|

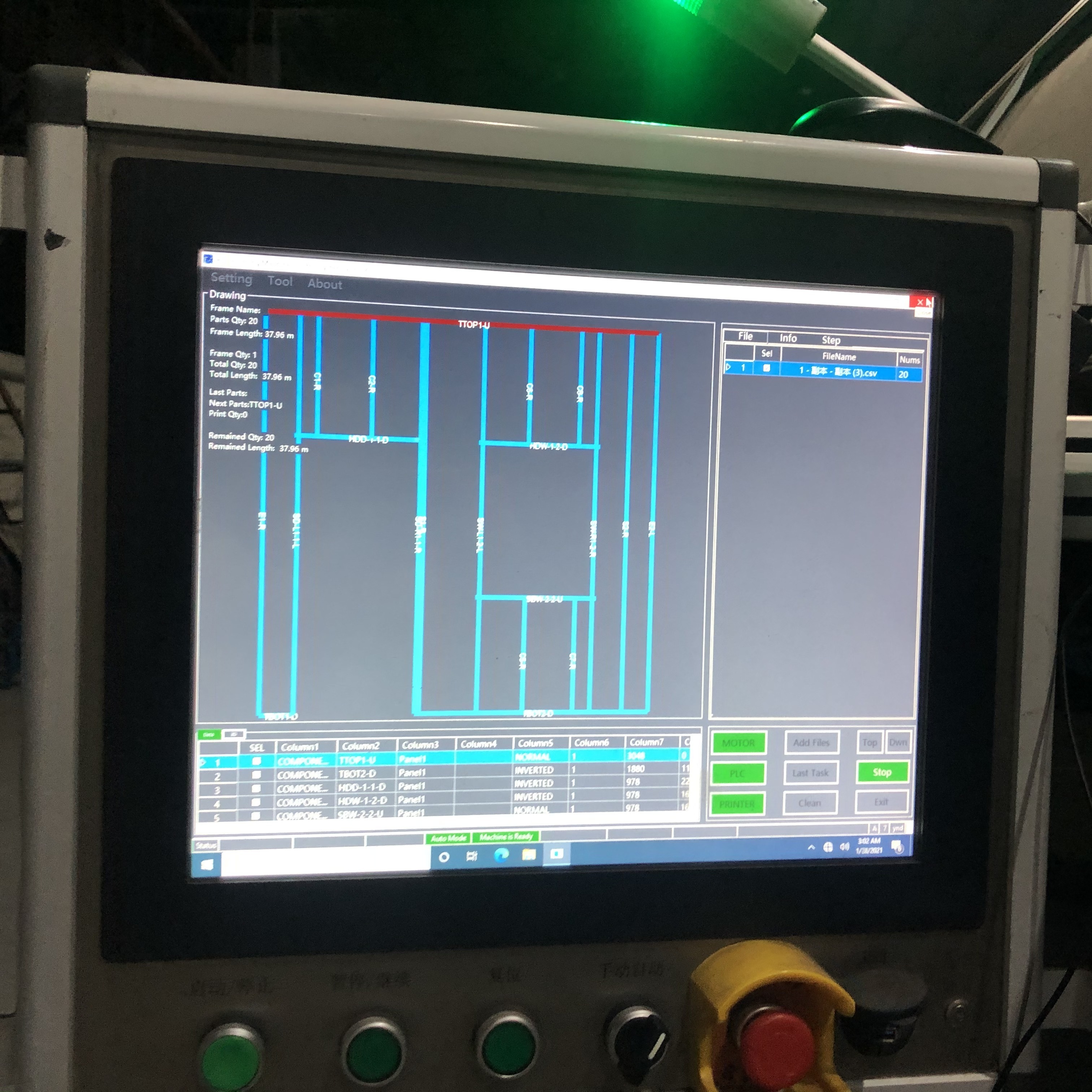

VERTEX BD house design software

1. The wall, floor and roof structure is produced automatically, saving design time.

2. Automatic 3D molding, insure 100% accuracy.

3. With analysis project function, the software can calculate bearing capacity.

4. Create frame work 3D map and 3D decoration view.

5. The whole building frame can be resolve to independent unit drawing.

6. Calculate the bill of material, including the needed steel, plates, thermal insulation material,doors and windows, screws and other matching material.

7. Create the processed data including the marked work piece, docking with the equipment.

8. Software maintenance and training fee.

9. Maintenance and supporting fee is USD 2200.00/Year. It’s for software update and optional.

1. The wall, floor and roof structure is produced automatically, saving design time.

2. Automatic 3D molding, insure 100% accuracy.

3. With analysis project function, the software can calculate bearing capacity.

4. Create frame work 3D map and 3D decoration view.

5. The whole building frame can be resolve to independent unit drawing.

6. Calculate the bill of material, including the needed steel, plates, thermal insulation material,doors and windows, screws and other matching material.

7. Create the processed data including the marked work piece, docking with the equipment.

8. Software maintenance and training fee.

9. Maintenance and supporting fee is USD 2200.00/Year. It’s for software update and optional.

Profile Drawing

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Light gauge steel construction is stronger and more durable than wood or concrete construction. Because light gauge steel framing is not biodegradable, it is not susceptible to decay or termite attack, and is moisture resistant so it will not shrink, rot, or warp in adverse weather conditions.

Light steel framing delivers a number of excellent benefits for construction projects of all types. Light steel framing provides several advantages for buildings and construction companies, from its cost-effectiveness to its versatility. It can be used for a variety of different applications and offers the benefits of rapid construction, durability, and even an eco-friendly building method. Light steel framing is easier to transport onto construction sites and can be an ideal choice for prefabrication too.

Application

Steel frame application

The steel framing used in light steel frame construction is typically made from galvanized or cold-formed steel. Galvanized steel is coated with a layer of zinc to protect it from corrosion, while cold-formed steel is made by bending flat sheets of steel into the desired shape without heating them.

Galvanized steel is preferred for external applications since it is more resistant to rust and corrosion compared to cold-formed steel. However, both types are lightweight, strong, and durable, making them ideal for use in modern building design.

Light steel framing is commonly used in residential and commercial construction projects, particularly for low-rise buildings up to four stories. Its advantages include quick and easy construction, energy efficiency, cost-effectiveness, and versatility in design.

Packing & Delivery

Customer's feedback

Maintance and the service of the machine

Machine maintenance

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily.

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Daily maintenance with meticulous care plays an important part in extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your daily.

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Hot Searches