- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHONGYI

-

Model Number:

-

G1.6

-

Measurement range:

-

0.025~10

-

Working pressure:

-

20 KPa

-

Operating temperature:

-

-20~+50℃

-

Level of protection:

-

IP65

-

Certification:

-

CE

Quick Details

-

Type:

-

Ultrasonic flow meters

-

Warranty:

-

1years

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZHONGYI

-

Model Number:

-

G1.6

-

Measurement range:

-

0.025~10

-

Working pressure:

-

20 KPa

-

Operating temperature:

-

-20~+50℃

-

Level of protection:

-

IP65

-

Certification:

-

CE

Product introduction:

Ultrasonic gas meter is a new type of all electronic metering combustion which uses the time difference of ultrasonic transmission in the medium to measure Gas meter, with high reliability, high precision, temperature and pressure compensation and other endogenous functions.

Technical principle:

Time difference method is adopted in ultrasonic measurement, and its working principle is to use a pair of ultrasonic transducers to alternate in phase (or at the same time) send and receive ultrasonic wave, and indirectly measure the fluid by observing the time difference between forward and reverse flow propagation of ultrasonic wave in the medium Flow rate, and then through the flow rate to calculate the flow rate of an indirect measurement method.

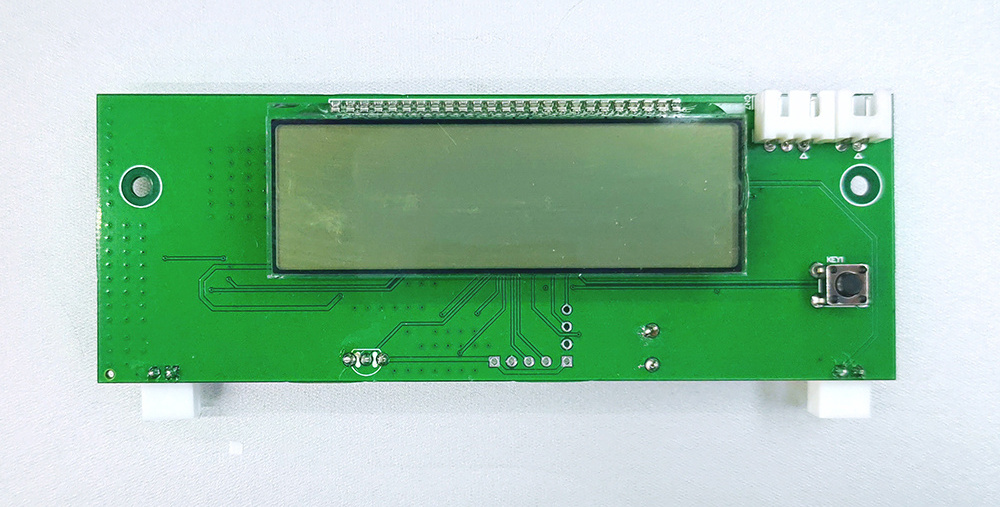

Product appearance:

Technical parameters:

|

Measurement grade

|

1.5

|

|

Maximum pressure loss

|

250 Pa

|

|

Applicable gas source

|

Natural gas, liquefied petroleum gas

|

|

Applicable temperature

|

-25℃~55℃

|

|

relative humidity

|

≤ 95%

|

|

atmospheric pressure

|

86kPa~106kPa

|

|

Maximum working pressure

|

10 KPa

|

|

Instantaneous maximum current

|

160 mA

|

|

Quiescent current

|

≤ 25 uA

|

|

Protection level

|

IP 54

|

Ultrasonic characteristics:

(1) Improve the measurement accuracy: correct separately for each flow area to achieve full range and high accuracy correction; ultra-low starting flow point, fine air flow can also be detected and measured; wide range measurement; full electronic measurement

(2) Improve measurement correction: temperature and pressure compensation, increase revenue;

(3) Stable / safe / anti theft: excellent anti-theft performance; small flow leakage protection; over flow gas protection

(2) Improve measurement correction: temperature and pressure compensation, increase revenue;

(3) Stable / safe / anti theft: excellent anti-theft performance; small flow leakage protection; over flow gas protection

Product advantages:

1) Support post payment meter reading settlement and background prepayment settlement;

2) Support network automatic meter reading;

3) Support remote valve control;

4) Support remote parameter configuration;

5) Support automatic alarm of equipment fault;

6) Support monthly data freezing management and active upload of data once a day at most;

7) Real time temperature compensation;

8)Real time pressure compensation (optional).

2) Support network automatic meter reading;

3) Support remote valve control;

4) Support remote parameter configuration;

5) Support automatic alarm of equipment fault;

6) Support monthly data freezing management and active upload of data once a day at most;

7) Real time temperature compensation;

8)Real time pressure compensation (optional).

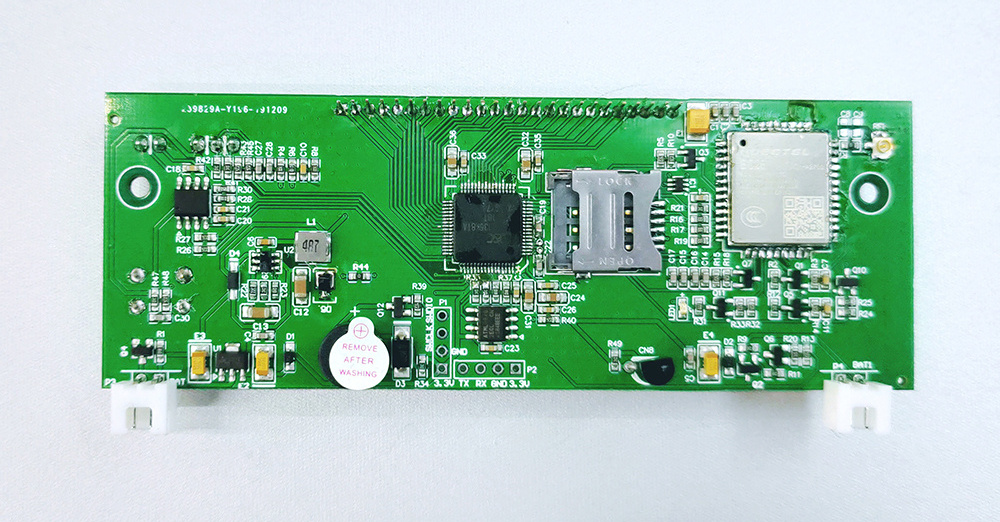

Communication introduction

NB-IOT

The main chip of NB-IOT communication module adopts the high-performance embedded ARM cortex-m3 32-bit RISC controller, which

ensures the stability of the device with multilevel software detection and multiple hardware protection mechanisms.It is composed

of the powerful ARM cortex-m3 32-bit RISC microcontroller and NB-IOT wireless spread spectrum chip .

Product features are as follows:

(1) nb-iot module adopts LGA package, small in size, compact in structure and easy for embedded product application;

(2)wide voltage supply design, suitable for more applications;

(3) integrated TCP/UDP and other data transmission protocols and embedded rich network service protocols, easy to design and

upgrade products;

(4)passed the high and low temperature test, in line with the industrial environment;

(5)provide upper computer software to realize on-site test equipment and compatibility with existing equipment;

(6) deep coverage: 100 times more coverage than GSM;

(7) mass connection: each community can provide 50,000-100,000 connections;

Low power consumption: the useful life of terminal battery is over 6 years;

The main chip of NB-IOT communication module adopts the high-performance embedded ARM cortex-m3 32-bit RISC controller, which

ensures the stability of the device with multilevel software detection and multiple hardware protection mechanisms.It is composed

of the powerful ARM cortex-m3 32-bit RISC microcontroller and NB-IOT wireless spread spectrum chip .

Product features are as follows:

(1) nb-iot module adopts LGA package, small in size, compact in structure and easy for embedded product application;

(2)wide voltage supply design, suitable for more applications;

(3) integrated TCP/UDP and other data transmission protocols and embedded rich network service protocols, easy to design and

upgrade products;

(4)passed the high and low temperature test, in line with the industrial environment;

(5)provide upper computer software to realize on-site test equipment and compatibility with existing equipment;

(6) deep coverage: 100 times more coverage than GSM;

(7) mass connection: each community can provide 50,000-100,000 connections;

Low power consumption: the useful life of terminal battery is over 6 years;

After the communication module is superimposed, if combined with the integrated energy

control platform software independently developed by the company,It can realize:

* Unmanned, reduced manpower.

●automatic data logging.

●Industrial-grade communication equipment ensures the safety and reliability of meter reading.

●Complete system log traceability is available.

●Visual graphics, data statistics.

●Meter status alarm;When low-power and low-volume magnetic attack sampling fault leakage alarm (external leakage alarm) occurs,

real-time alarm information is uploaded to the background application platform.

●Control the gasmeter valve switch through background application software (desktop WEB and mobile APP).

●When the meteris removed or attacked by external forces, the information will be transmitted to the background application

platform in real time

●The stability of data transmission can be monitored.

●automatic data logging.

●Industrial-grade communication equipment ensures the safety and reliability of meter reading.

●Complete system log traceability is available.

●Visual graphics, data statistics.

●Meter status alarm;When low-power and low-volume magnetic attack sampling fault leakage alarm (external leakage alarm) occurs,

real-time alarm information is uploaded to the background application platform.

●Control the gasmeter valve switch through background application software (desktop WEB and mobile APP).

●When the meteris removed or attacked by external forces, the information will be transmitted to the background application

platform in real time

●The stability of data transmission can be monitored.

Product operating environment

1.temperature:-10℃~40℃;

2.working pressure:0.5kPa~30kPa;

3.relative humidity:≤93%;

4.atmospheric pressure:86kPa~106kPa;

5.This series of gas meters is applicable to the measurement of urban pipeline gas, natural gas and liquefied petroleum gas;

6.The gas used should comply with the relevant provisions of the state, can not contain water to prevent condensation water will

be frozen meter;

7.It should be installed in a dry and ventilated place, strictly prohibited in the bedroom or bathroom;

8.It should not be installed in the place of serious corrosion to the table;

9.Adequate safe distance from furnace and other sources of fire;

10.In order to avoid condensed water into the table, the table should be installed horizontally at the high point of the pipeline.

2.working pressure:0.5kPa~30kPa;

3.relative humidity:≤93%;

4.atmospheric pressure:86kPa~106kPa;

5.This series of gas meters is applicable to the measurement of urban pipeline gas, natural gas and liquefied petroleum gas;

6.The gas used should comply with the relevant provisions of the state, can not contain water to prevent condensation water will

be frozen meter;

7.It should be installed in a dry and ventilated place, strictly prohibited in the bedroom or bathroom;

8.It should not be installed in the place of serious corrosion to the table;

9.Adequate safe distance from furnace and other sources of fire;

10.In order to avoid condensed water into the table, the table should be installed horizontally at the high point of the pipeline.

Installation and safety matters

1.Before installation, the gas meter should be inspected first for appearance and then for sealing performance, so as to prevent installation and use of the gas meter that may cause damage during transportation.

2.When installing the gas meter, it should be noted that the distance between the center of the pipeline connected with the gas meter should be consistent with the distance between the center of the gas meter. It should not be forced to connect and twist to avoid leakage at the connection of the gas meter.

3.The gas meter should have sufficient safe distance from the stove and other fire sources.

4.Keep in mind:The air in the pipeline and gas meter should be emptied before ignition.Gas mixed with air can easily explode when it meets spark.

5.During transportation, storage and installation of gas meters, care should be taken to prevent falling upside down and water entering.

6.The fuel gas used should meet the requirements of the national standards and should not contain moisture. The condensed water in fuel gas will freeze the table and cannot operate normally

7.In order to avoid condensate water into the gas meter, the gas meter should be installed horizontally at the high point of the pipeline when installation should pay attention to the top of the case arrow, indicating the direction of gas flow, should not be connected to the reverse (because the table has anti-retrograde device).

8.The gas meter should be installed in a dry and ventilated place. It is strictly prohibited to install the gas meter in the

bedroom and bathroom, and should not be installed in the place where the gas meter is seriously corroded.

9.When the pipeline system leaks, it is forbidden to leak the open fire. When the pilot fire is carried out, the air in the gas

meter must be discharged to prevent accidents

10.In case of malfunction, please do not disassemble by yourself, please ask the technical personnel of gas company for

maintenance.

11.In case of gas leakage, first close the front table valve, immediately open doors and Windows ventilation.

12.Do not use open fire leak detection, carefully with soap and water leak detection.

13.This meter can not be used in the use of strong caustic soda gasoline alcohol solvent cleaning.

2.When installing the gas meter, it should be noted that the distance between the center of the pipeline connected with the gas meter should be consistent with the distance between the center of the gas meter. It should not be forced to connect and twist to avoid leakage at the connection of the gas meter.

3.The gas meter should have sufficient safe distance from the stove and other fire sources.

4.Keep in mind:The air in the pipeline and gas meter should be emptied before ignition.Gas mixed with air can easily explode when it meets spark.

5.During transportation, storage and installation of gas meters, care should be taken to prevent falling upside down and water entering.

6.The fuel gas used should meet the requirements of the national standards and should not contain moisture. The condensed water in fuel gas will freeze the table and cannot operate normally

7.In order to avoid condensate water into the gas meter, the gas meter should be installed horizontally at the high point of the pipeline when installation should pay attention to the top of the case arrow, indicating the direction of gas flow, should not be connected to the reverse (because the table has anti-retrograde device).

8.The gas meter should be installed in a dry and ventilated place. It is strictly prohibited to install the gas meter in the

bedroom and bathroom, and should not be installed in the place where the gas meter is seriously corroded.

9.When the pipeline system leaks, it is forbidden to leak the open fire. When the pilot fire is carried out, the air in the gas

meter must be discharged to prevent accidents

10.In case of malfunction, please do not disassemble by yourself, please ask the technical personnel of gas company for

maintenance.

11.In case of gas leakage, first close the front table valve, immediately open doors and Windows ventilation.

12.Do not use open fire leak detection, carefully with soap and water leak detection.

13.This meter can not be used in the use of strong caustic soda gasoline alcohol solvent cleaning.

Factory environment

Qualification:

Packing and delivery:

Hot Searches