- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

zzknown

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

1000*450*850mm

-

Motor Power (Kw):

-

7.5kw

-

Power (kW):

-

7.5kw

-

Weight (KG):

-

350 KG

-

Name Of The Pellet Machine:

-

Wood pellet machine

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

100-150kg/h

-

Color:

-

Customer's Request

-

Spare parts:

-

Flat Die+ Rollers

-

Ideal moisture:

-

Biomass Pellet 15-20%

-

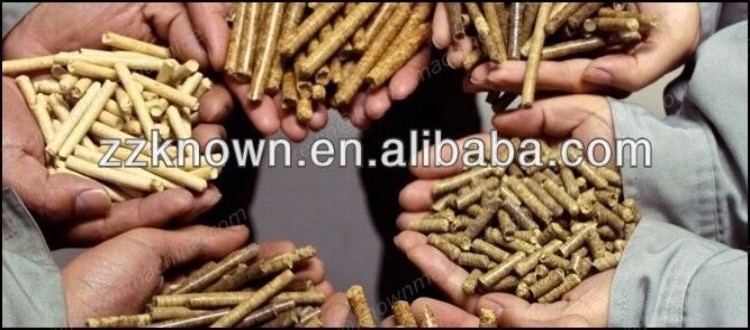

Pellet size:

-

3-12mm

-

Keywords:

-

Fuel Pellets Making Machine

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

Quick Details

-

Pellet Diameter (mm):

-

3 - 12

-

Output (kg/h):

-

100 - 120 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zzknown

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

1000*450*850mm

-

Motor Power (Kw):

-

7.5kw

-

Power (kW):

-

7.5kw

-

Weight (KG):

-

350 KG

-

Name Of The Pellet Machine:

-

Wood pellet machine

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

100-150kg/h

-

Color:

-

Customer's Request

-

Spare parts:

-

Flat Die+ Rollers

-

Ideal moisture:

-

Biomass Pellet 15-20%

-

Pellet size:

-

3-12mm

-

Keywords:

-

Fuel Pellets Making Machine

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

CE Approved Wood Pellet Machine Small Capacity 100-120KG/H Sawdust Biomass Pellet Mill Hot Sell in Chile

Support Sample Order, If you need 1 set, please contact me directly ^_^

My Name: Tona

My Whatsapp: 008617719817331

My Email: tona@knownmachine.com

My Name: Tona

My Whatsapp: 008617719817331

My Email: tona@knownmachine.com

Product Description

♦ The Development Prospect Of The Wood Pellets Production

Every year millions tons of Agricultural / Biomass waste are generated. These are either non used or burnt inefficiently in their loose form causing air pollution. Now we provide the solution to convert this wastage into best form. These wastage can easily convert into high density fuel (briquettes) with the help of Pellet Mill.

♦ The Home Used of Wood Pellet Mill

Mainly used for home and small process plant, It is mainly used for Wood, Straw, Cotton stalk, Rice husk, Peanut shell, Bamboo, Empty fruit branch, Pulverized coal and waste paper etc. Advantages of out products is high density, high fuel value, low moisture and low ash content, machines running by reduction gears. Details, as follows:

|

MODEL NO.

|

OUTPUT(KG/H)

|

POWER (KW)

|

PELLET DIAMETER(mm)

|

SIZE(mm)

|

WEIGHT(KG

|

|

KN-D-200

|

100-120

|

7.5

|

2.5-10

|

1000*450*850

|

350

|

|

KN-D-250

|

180-200

|

15

|

2.5-10

|

1200*550*1050

|

550

|

|

KN-D-300

|

200-300

|

22

|

2.5-10

|

1250*600*1100

|

750

|

KN-D-200 wood pellet machine

KN-D-250 and KN-D-300 wood pellet machine (SAME APPEARANCE)

♦ The I ndustrial (Commercial) Used of Wood Fuel Pellet Making Machine

Suitable used for the small pellet production line or industrial pellet plant. Details, as follows:

|

MODEL NO.

|

OUTPUT(KG/H)

|

POWER (KW)

|

PELLET DIAMETER(mm)

|

SIZE(mm)

|

WEIGHT(KG

|

|

KN-D-350

|

400-500

|

30

|

2.5-10

|

1650*700*1300

|

1000

|

|

KN-D-450

|

600-700

|

37

|

2.5-10

|

1300*700*1500

|

1450

|

KN-D-350 wood pellet machine

KN-D-350 wood pellet machine

♦ Big Capacity Vertical Ring Die Pellet Mill

We also have the KN-D-800 with 90Kw power and the KN-D-1000 with 110 power of big flat die series wood pellet machine. However, compared with the vertical ring die pellet mill, if the capacity you wanted is bigger than 800kg/h, we are recommend our Vertical ring die pellet mill to you

. Details, as follows:

|

MODEL NO.

|

OUTPUT

(Ton/H)

|

POWER (KW)

|

PELLET DIAMETER(mm)

|

SIZE(mm)

|

WEIGHT(KG

|

|

KN-SD-450

|

0.8-1.2

|

55

|

6-12

|

1400*750*1550

|

2800

|

|

KN-SD-550

|

1.5-2

|

90

|

6-12

|

1900*950*1800

|

4500

|

|

KN-SD-800

|

2-3

|

160

|

6-12

|

2500*1350*2100

|

7000

|

|

KN-SD-1000

|

3-4

|

200

|

6-12

|

2650*1450*2100

|

8500

|

• Our wood pellet machine with the automatic lubricating system and the cooling and dedusting system

1. Automatic lubricating system can be used to ensure continue working in 24 hours per day.

-

-Automatic lubricating system for gear box

-

-Automatic lubricating system for rollers

2.

Cooling and dedusting system:

--

Reduce the temperature of wood pellet machine's working space, the wood pellet machine will working more stable.

--

Remove the dust and water vapour, ensure the good quality of final pellets with low moisture.

--

Greatly improve working environment for workers.

Packing & Delivery

Biomass Pellet Mill Machine Packing and Shipping

Packed in standard wooden case

Shipping by sea

Our service

|

1.

|

Pre-sales service:

|

|

1)

|

Sales person,project manager,technology engineer,accountant staff

|

|

2)

|

Professional responsing-team:would be very fast and exactly to send you offer

|

|

2.

|

Online / sale service:

|

|

1)

|

Super and solid quality

|

|

2)

|

Fastly delivery

|

|

3)

|

Standard export package or as your demand

|

|

3.

|

After-sale service:

|

|

1)

|

Assistance to build factory

|

|

2)

|

Repairing and maintenance if any problem occur in the warranty

|

|

3)

|

Installation and clerks training

|

|

4)

|

Spare and wearing parts for free or with big discount

|

|

5)

|

Any feedback of machines can be told us, and we will try our best to support you

|

|

4.

|

Other cooperation service:

|

|

1)

|

Technology knowledge share

|

|

2)

|

Factory building advising

|

|

3)

|

Any other machines (we don't have) help customer finding without any benefit

|

Hot Searches