②Cat litter is mainly used in cat toilets to deodorize and coagulate

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v

-

Weight (KG):

-

1500

-

Power (kW):

-

120

-

Name:

-

Cat Litter Production Line

-

Capacity:

-

1-2T/H

-

Certification:

-

CE

-

After Warranty Service:

-

Remote video service

-

Package:

-

Wooden Package

-

Material:

-

Stainless Steel 304

-

Granulate rate:

-

95%

-

Color:

-

Customer's Request

-

Feature:

-

High Working Efficiency

-

Granulate size:

-

3-8mm

Quick Details

-

Output (kg/h):

-

2000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GATE

-

Voltage:

-

220v/380v

-

Weight (KG):

-

1500

-

Power (kW):

-

120

-

Name:

-

Cat Litter Production Line

-

Capacity:

-

1-2T/H

-

Certification:

-

CE

-

After Warranty Service:

-

Remote video service

-

Package:

-

Wooden Package

-

Material:

-

Stainless Steel 304

-

Granulate rate:

-

95%

-

Color:

-

Customer's Request

-

Feature:

-

High Working Efficiency

-

Granulate size:

-

3-8mm

Cat Litter Production Line

①The fertilizer pellets are packaged and sold

What raw materials can be used to make cat litter?

1、One of the most common cat litter ingredients is clay /usually a natural mineral known as bentonite. This type of cat litter is

usually divided into two main types: sodium bentonite (sodium silicate) and calcium bentonite (calcium silicate). Silicone cat

2、Silicone cat litter is made with silica gel pellets and has excellent absorption properties /but is relatively expensive.

3、Wood shavings: some cat litters are made with wood shavings such as pine /cedar or pulp. It is biodegradable and environmentally

friendly.

4、 Plant fibres: Some cat litters are made using plant fibres such as corn /wheat and soya bean dregs. Environmentally friendly

and often biodegradable /but may not be as absorbent as other types of cat litter.

5、Recycled Pulp: Recycled pulp cat litters are made from waste paper /and they are often an environmentally friendly choice!

6、Bentonite /wood chips /vermiculite /diatomaceous earth /bean dregs /corn starch /puffed corn /montmorillonite powder /coffee

grounds /etc. 7、bentonite clay /talcum powder /spices

All of the above raw materials can be used to make cat litter, so if you have a better idea or would like to experiment as well, please contact us immediately! We can help you to do experiments

usually divided into two main types: sodium bentonite (sodium silicate) and calcium bentonite (calcium silicate). Silicone cat

2、Silicone cat litter is made with silica gel pellets and has excellent absorption properties /but is relatively expensive.

3、Wood shavings: some cat litters are made with wood shavings such as pine /cedar or pulp. It is biodegradable and environmentally

friendly.

4、 Plant fibres: Some cat litters are made using plant fibres such as corn /wheat and soya bean dregs. Environmentally friendly

and often biodegradable /but may not be as absorbent as other types of cat litter.

5、Recycled Pulp: Recycled pulp cat litters are made from waste paper /and they are often an environmentally friendly choice!

6、Bentonite /wood chips /vermiculite /diatomaceous earth /bean dregs /corn starch /puffed corn /montmorillonite powder /coffee

grounds /etc. 7、bentonite clay /talcum powder /spices

All of the above raw materials can be used to make cat litter, so if you have a better idea or would like to experiment as well, please contact us immediately! We can help you to do experiments

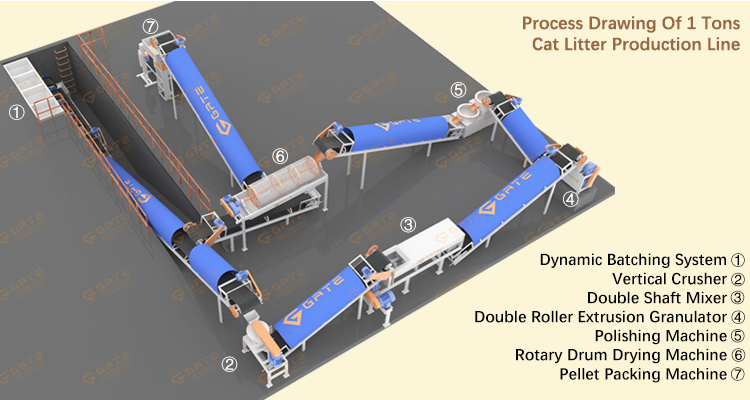

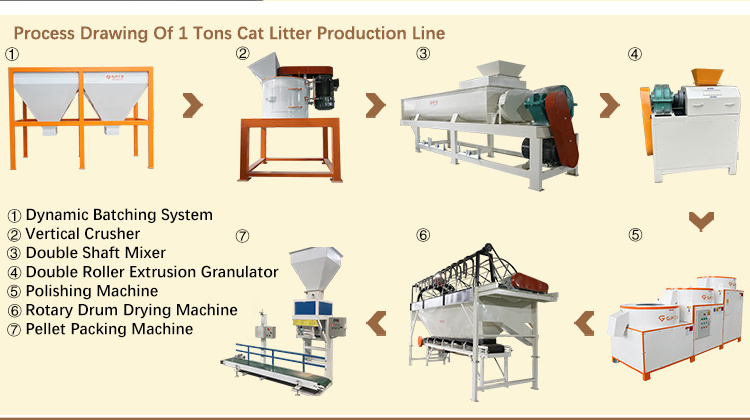

Production process diagram and 3D diagram of 1T/H cat litter production line

|

Product Name

|

Yield

|

Detail

|

Speed

|

Power

|

|

Dynamic Batching System

|

PVC drive belt: width 0.5 m, length 2 m

|

SBD series reducer

|

5-10 m/min

|

1.1-2.2KW

|

|

Vertical Crusher

|

1-12t/h

|

Crushing fineness: 0.5-5mm

|

1450r/min

|

7.5-37KW

|

|

Double Roller Extrusion Granulator

|

0.8-4.5t/h

|

ZY series reducer

|

1450r/min

|

11-30KW

|

|

Polishing Machine

|

2-10t/h

|

Double bearing

|

1450r/min

|

3-7.5KW

|

|

Rotary Drum Drying Machine

|

1-25t/h

|

ZQ series reducer

|

1450r/min

|

5.5-22KW

|

|

Pellet Packing Machine

|

4-20 bags/minute

|

ZQ series reducer

|

1450r/min

|

50Hz/60Hz/220V/380V

|

Production Process Diagram And 3D Diagram Of 2T/H Cat Litter Production Line

Our Service

Pre-sale

Our account manager will communicate with you the product requirements related to your machine

We offer free product plans, packaging drawings and 3D renderings to save your budget

We will provide our own quotation and proof of our machines

We have a professional R & D department, to provide you with the most professional technical support

We can make granulation experiment according to your raw materials

On sale

1、During the production of the equipment, we will feed back the production progress to you

2、We support customer on-site inspection,video inspection, third party inspection, factory inspection agency inspection

3、

We can provide certificate of origin, customs clearance and other certificates

4、We offer you a free test service before the machine leaves the factory

5、

We also provide equipment packing diagram

After sale

1、If you need to install, we have a professional overseas installation team ,

We will provide you with installation drawings or a video guide for making the installation

2、We support to provide you with free accessories within one year of purchase of machine equipment

3、We will provide a five year warranty on important parts of the equipment

Transaction Customer

Customer evaluation & Production site

This is part of our customer site and customer praise display, if you want to communicate with these customers, please contact us

Hot Searches