- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas

-

vibration form:

-

platform vibration

-

pallet size:

-

680x530mm

-

molding size:

-

20s

-

overall power:

-

14.25KW

-

Certification:

-

CE/SGS

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

20000pcs per day

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas

-

vibration form:

-

platform vibration

-

pallet size:

-

680x530mm

-

molding size:

-

20s

-

overall power:

-

14.25KW

-

Certification:

-

CE/SGS

QT3-15 color paver block machine /brick machine /block making machine

ⅠBrief introduction

This color paver forming mache is a practical machine that simple in structure, artistic in figure. Especially suitable to the production of the paving brick,bread brick , it can produce various kinds of paving bricks,roads bricks etc.

ⅡControl system:

Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trained one to the operator.

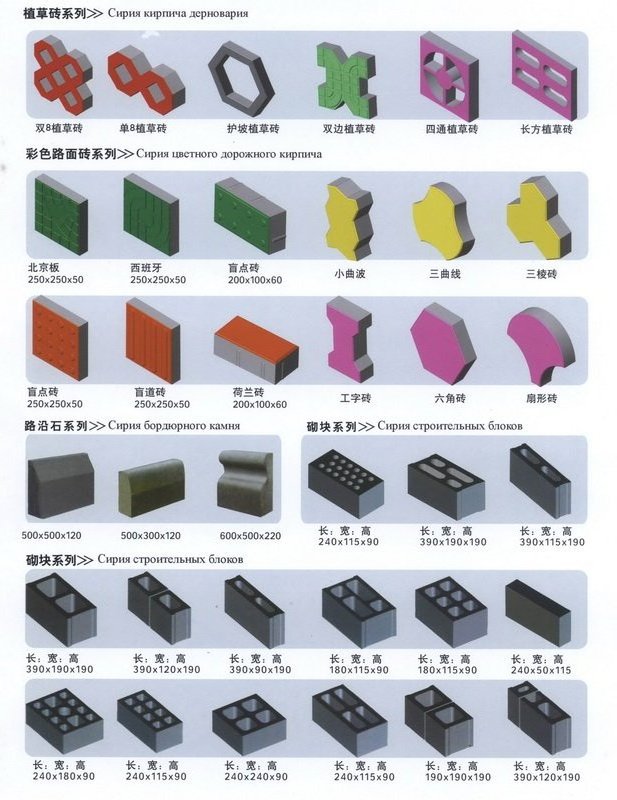

Product scope:

It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks,hollow blocks, perforated bricks, and standard bricks etc.

Ⅲ Main Technical Specifications

| Ⅲ Main Technical Specifications | |||||

| Main vibration form | Platform vibration | ||||

| Cycle Time | 20 seconds | ||||

| Overall weight | 2000kg | ||||

| Motors Power | 14.25KW | ||||

| overalldimension | 2200*2150*2350 | ||||

| Pallet Size | 680*530(mm) | ||||

| Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, expanded perlite, and other industrial wastes | ||||

| Applied Products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. | ||||

| Samples | Size mm |

Cycle

molding |

QTY

/Mould |

Per hour | |

| Procous brick | 200*100*90 | 15--25s | 10 | 1500~1800pcs | |

| Solid block |

220*112.5*60 |

15-25s | 8 | 1200~1400pcs |

Pre-sale service support:

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers.

During-sale service support:

Assist clients to finish the factory planning. Before delivery equipment to customer s, complete debugging and checking. Provide a full instruction manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit.

After-sale service support:

Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.