- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3700

-

Weight:

-

750

-

Product name:

-

Flow Ethanol Separator Machine Continuous Centrifuge Industrial Price

-

Diameter(mm):

-

600

-

Capacity (L):

-

40

-

Maximum loading limit:

-

60

-

The separation factor was:

-

755r / g

-

Motor power:

-

3kw

-

Weight of the whole machine:

-

650 kg

-

Drum thickness:

-

8mm

-

Shell thickness:

-

5mm

-

Material:

-

304SS

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZKD

-

Voltage:

-

220V

-

Power:

-

3700

-

Weight:

-

750

-

Product name:

-

Flow Ethanol Separator Machine Continuous Centrifuge Industrial Price

-

Diameter(mm):

-

600

-

Capacity (L):

-

40

-

Maximum loading limit:

-

60

-

The separation factor was:

-

755r / g

-

Motor power:

-

3kw

-

Weight of the whole machine:

-

650 kg

-

Drum thickness:

-

8mm

-

Shell thickness:

-

5mm

-

Material:

-

304SS

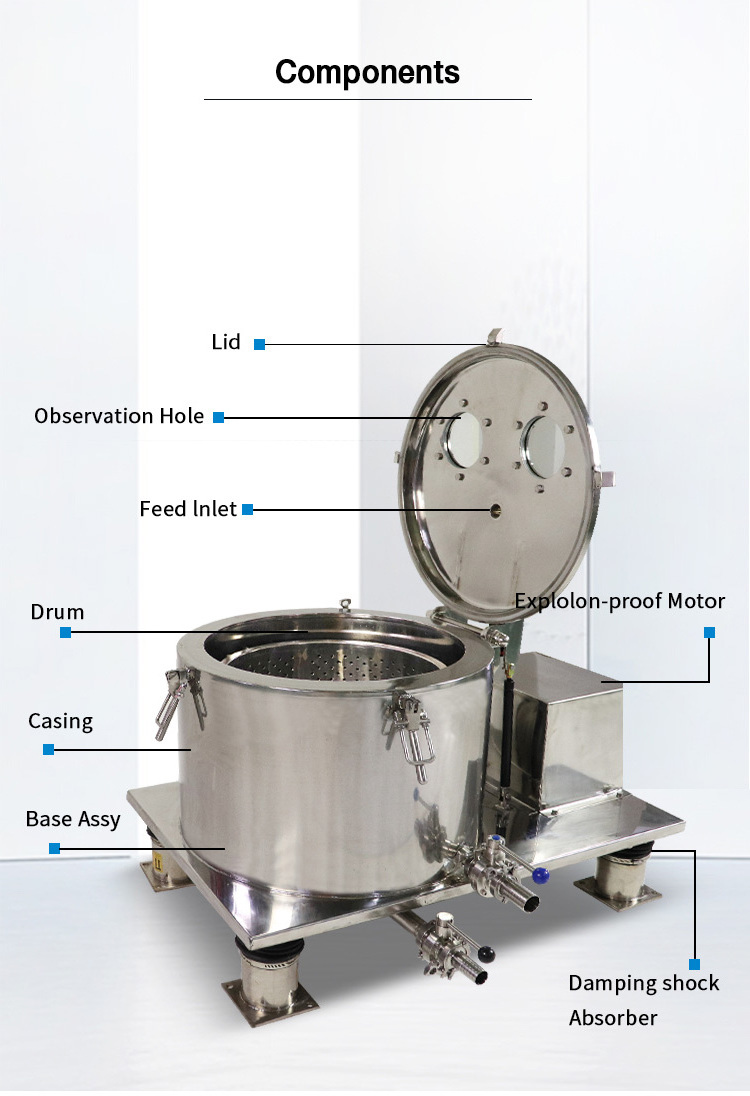

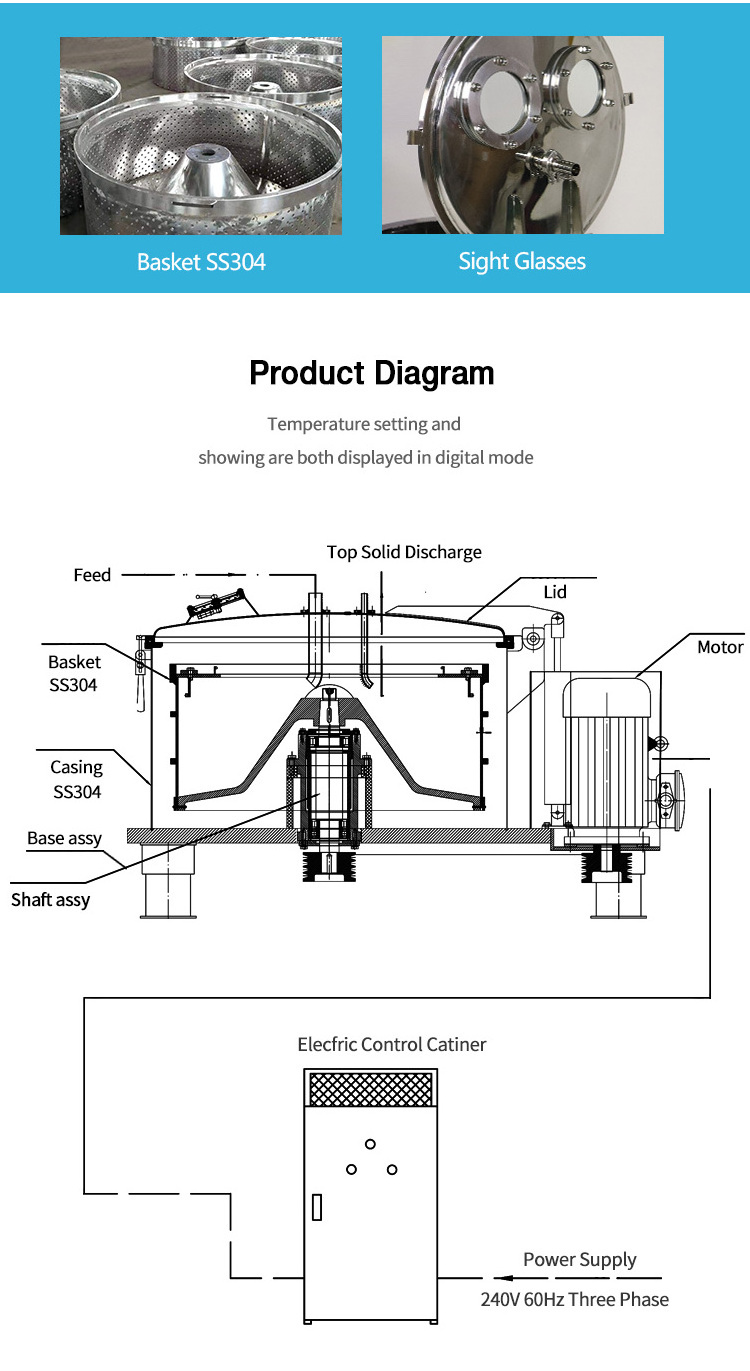

Flow Ethanol Separator Machine Continuous Centrifuge Industrial Price

The Tubular Refrigerated Lab Oil Centrifuge Machine is top discharging, hermetic closure type equipment. The material is fed into the drum through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force field, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the drum and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

Tubular Refrigerated Lab Oil Centrifuge Machine is a type of centrifugal separation machinery with high scientific content, and several configuration options are available. Featuring asepsis, sanitation, enclosed explosion-proof, multiple safety protections and several configuration options, this series centrifuge is controlled by a fully-automatic program, and has been widely used in such industries as pharmacy, fine chemistry and food.

Tubular Refrigerated Lab Oil Centrifuge Machine The motor drives the basket to rotate at high speed through the belt, and under the control of pre-written program, the material to be separated is fed into the basket through the feed system. After the material is filtered through the filtration medium (filter cloth/screen) under the action of centrifugal force, the liquid phase discharges out of the centrifuge through the liquid pipeline, and the solid phase is retained in the basket. A material detection device is used to detected material filling position in real-time manner, and when the solid cake deposited in the basket reaches the specified holding capacity of the centrifuge, feeding stops. Then wash and dry the solid cake. After the solid cake meets requirements for knock-out, the centrifuge reduces to the scraping rate, under the hydraulic (pneumatic) control, the scraper device removes the solid cake, and then the cake id discharged at bottom outlet of the centrifuge.