- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhuoheng

-

Voltage:

-

380V/50HZ

-

Power:

-

27/31/45kw

-

Dimension(L*W*H):

-

20/25/35*4*4m

-

Warranty:

-

2 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Pasta Production Line

-

Function:

-

Multifunction

-

Material:

-

Stainless Steel

-

Product name:

-

Pasta macaroni spaghetti production machine line

-

Usage:

-

Simple Operation

-

Capacity:

-

80-300kg/h

-

Color:

-

Silver

-

Export countries:

-

Indonesia

-

Feature:

-

Low Energy High Speed

-

Certification:

-

CE GOST TUV BV

Quick Details

-

Production Capacity:

-

80-300kg/h

-

Type:

-

Pasta macaroni spaghetti production machine line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhuoheng

-

Voltage:

-

380V/50HZ

-

Power:

-

27/31/45kw

-

Dimension(L*W*H):

-

20/25/35*4*4m

-

Warranty:

-

2 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Pasta Production Line

-

Function:

-

Multifunction

-

Material:

-

Stainless Steel

-

Product name:

-

Pasta macaroni spaghetti production machine line

-

Usage:

-

Simple Operation

-

Capacity:

-

80-300kg/h

-

Color:

-

Silver

-

Export countries:

-

Indonesia

-

Feature:

-

Low Energy High Speed

-

Certification:

-

CE GOST TUV BV

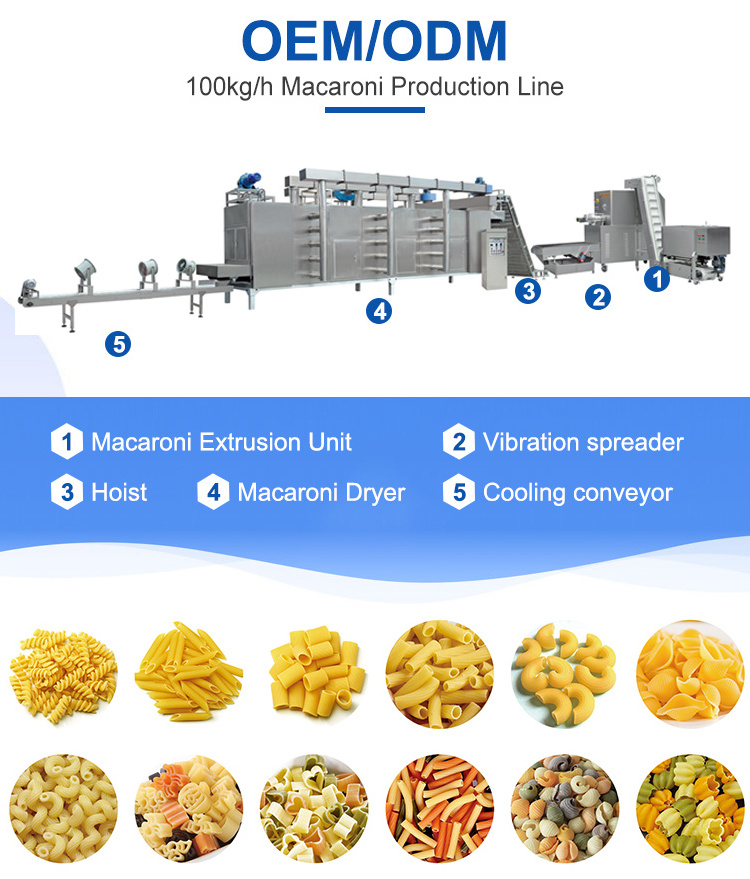

Products Description

|

Model

|

Installed Power

|

Consumption Power

|

Output

|

Host size

|

|

TXF-100

|

35kw

|

21kw

|

80-100kg/h

|

2.2x0.8x1.8m

|

|

TXF-200

|

50kw

|

37kw

|

200kg/h

|

3.9x2.8x4.5m

|

|

TXF-300

|

60kw

|

45kw

|

300kg/h

|

4.5x3.5x4.5m

|

|

|

100kg/h

|

200kg/h

|

|

Frequency converter

|

Delta

|

Delta

|

|

Electrical device

|

Schneider (such as: air switch, AC contactor)

|

Schneider (such as: air switch, AC contactor)

|

|

Main motor

|

Siemens

|

Siemens

|

|

PLC controller system

|

Schneider

|

Schneider

|

|

Host speed

|

25r/min

|

35r/min

|

|

Rotary cutting speed

|

100r/min

|

100r/min

|

Product Details

This machine line can use

wheat flour

as

main material

to make

different shapes pasta

, like tube , elbow , screw , shell etc .

Equipment configuration is perfect

, advanced production technology ; good quality products ,

simple and reliable operation

; is

the ideal equipment to make macaroni .

1.

Vacuum feeding system

: it will convey the flour to the storage hopper on top of the extrusion unit automatically.

2. Vacuum mixing and extrusion system : mixing and extrusion both are in vacuum condition, mixing includes high-speed mixing, primary mixing, secondary mixing.

3. Cutting system : speed adjustable

4. Vacuum creation system :consists of vacuum water tank, vacuum pump, vacuum buffer tank, vacuum pipe, vacuum pressure gauge, check valve and three-way deflation valve.

5.The automatic water supply system includes storage water tank, water pumps, water inlet and outlet pipes, quantitative valve, flow meter and water tower.

2. Vacuum mixing and extrusion system : mixing and extrusion both are in vacuum condition, mixing includes high-speed mixing, primary mixing, secondary mixing.

3. Cutting system : speed adjustable

4. Vacuum creation system :consists of vacuum water tank, vacuum pump, vacuum buffer tank, vacuum pipe, vacuum pressure gauge, check valve and three-way deflation valve.

5.The automatic water supply system includes storage water tank, water pumps, water inlet and outlet pipes, quantitative valve, flow meter and water tower.

The mold is imported from Italy, the material is copper + Teflon, and the mold plate is made of copper, which will make the surface of the produced product smoother.

Function:

Low temperature and slow baking ventilation

, with double doors, heat preservation material at

50-60℃ for 6-8 hours

, energy

saving 40%-50%

than conventional

Function: evenly heated, better baked products

Material: Food grade stainless steel

We can supply dryers of different heating ways, such as steam, electric, diesel, gas etc. We can customize the multi-layer dryer

according to your specific requirements

We can supply dryers of different heating ways, such as steam, electric, diesel, gas etc. We can customize the multi-layer dryer

according to your specific requirements

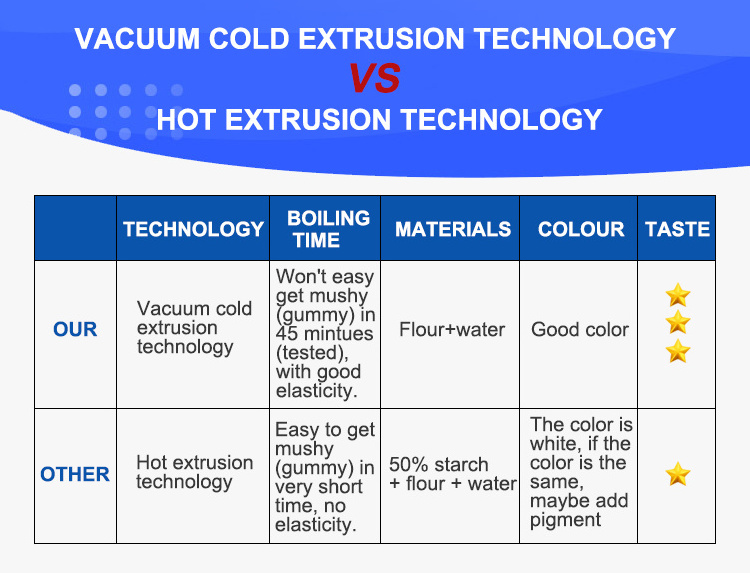

Technical Advantages :

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished .

Service Advantage

Communicating with customers and learn your requirement

Providing professional advisory services,

Providing solutions according to customers' require-ment, And offer the quotation

Providing on-site visit to our factory Providing samples

Send engineers for installation, trial running and training workers.

Handling the problems occurred during use.

Supply spare and wearing parts on discount.

Help customers to solve any other problems

Our Advantages

1.Manufacture

technology upgrade all the time according to market feedback

Strict quality control

reply in time to customers's inquiry

2.Online/Sale service

Fast and punctual delivery

Standard export package or as customers' need.

Assistance to build factory or your project.

Repair and maintenance if any problem occur during warranty.

3.After-sale service

Installation and staff training.

Spare and wearing parts for free or with big discount.

For any feedback from our customer,we will try our best to support you.

Technology share.

4.Other cooperate service

Factory building advising.

Business expansion

Hot Searches