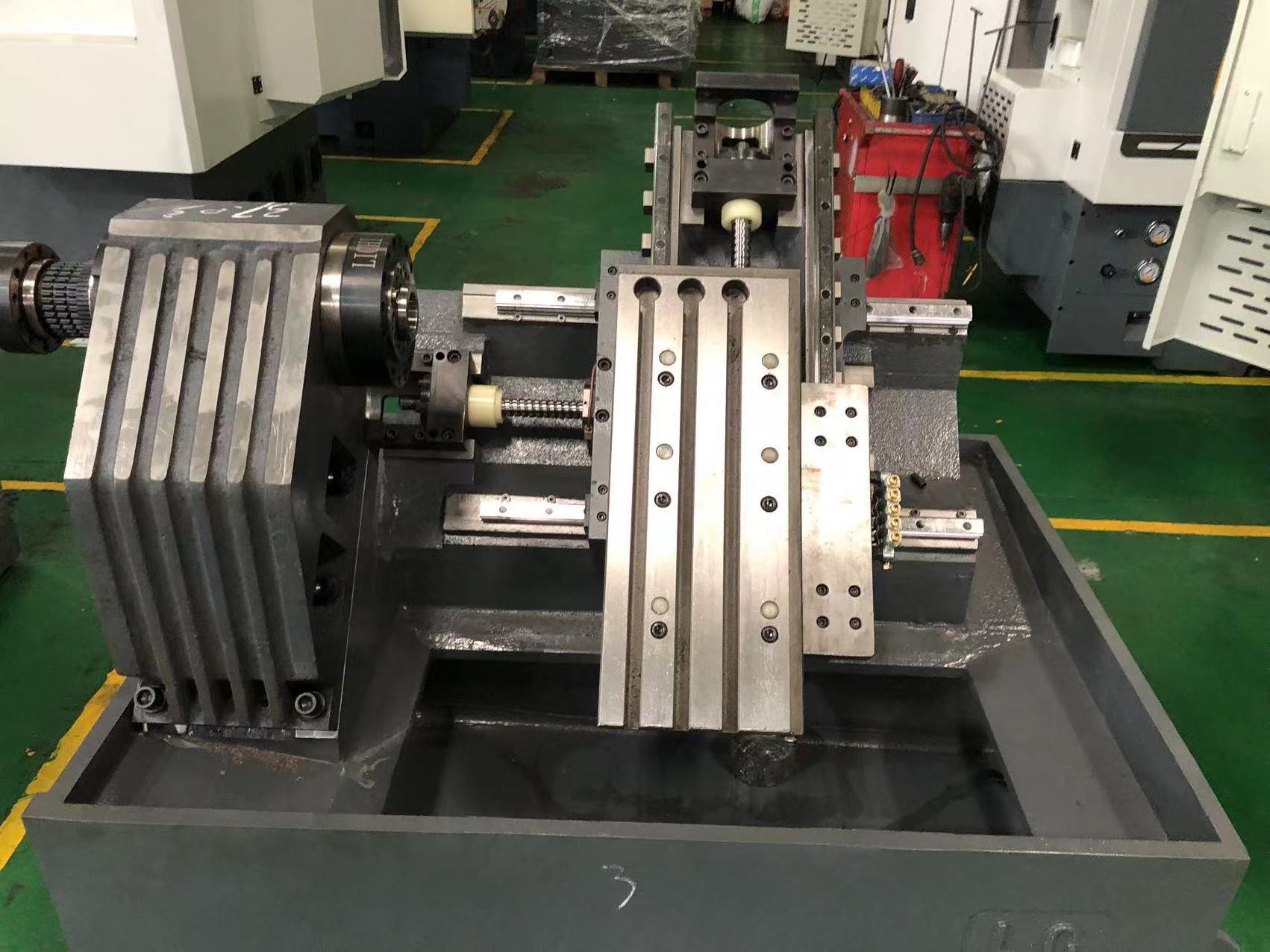

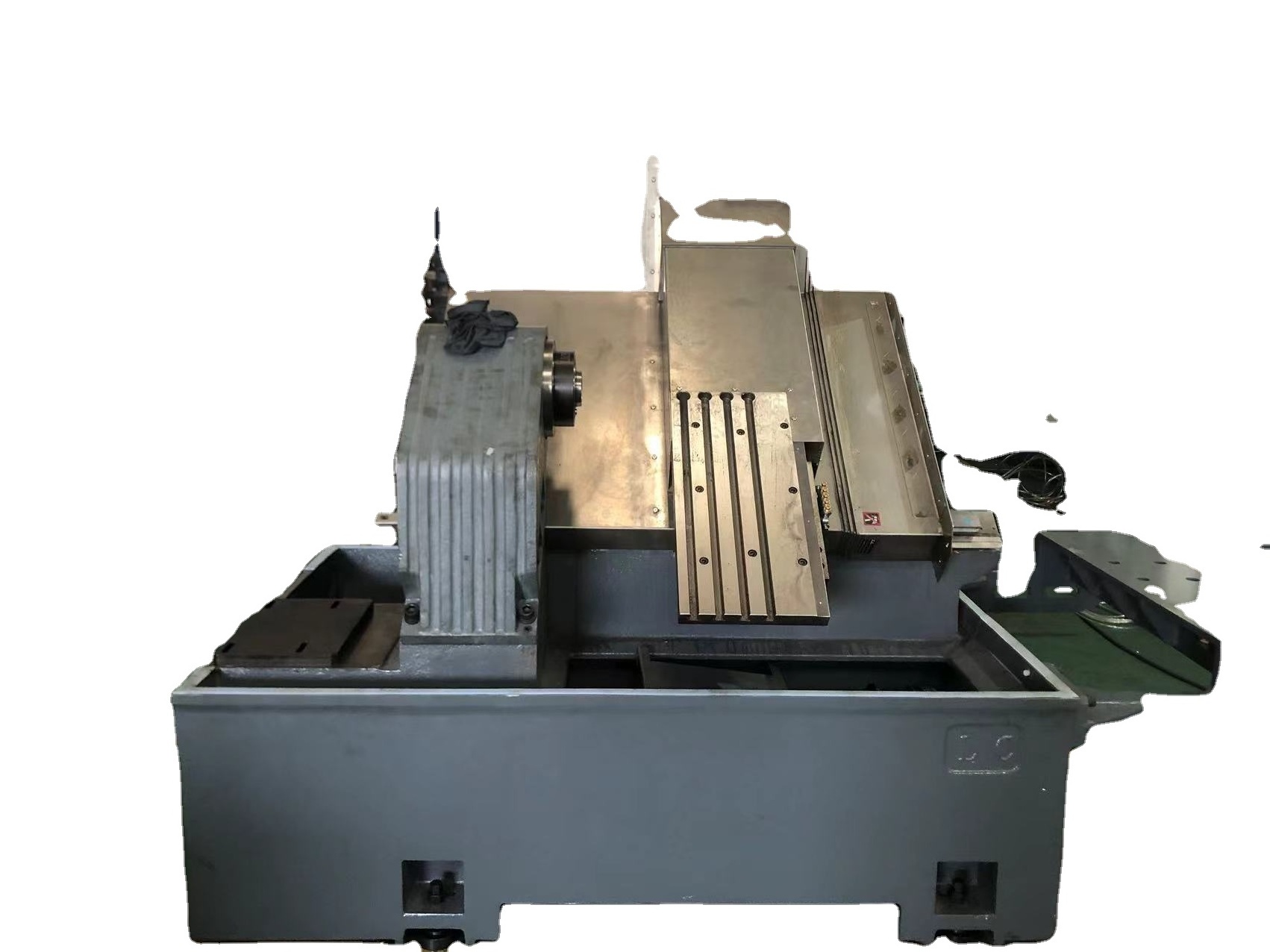

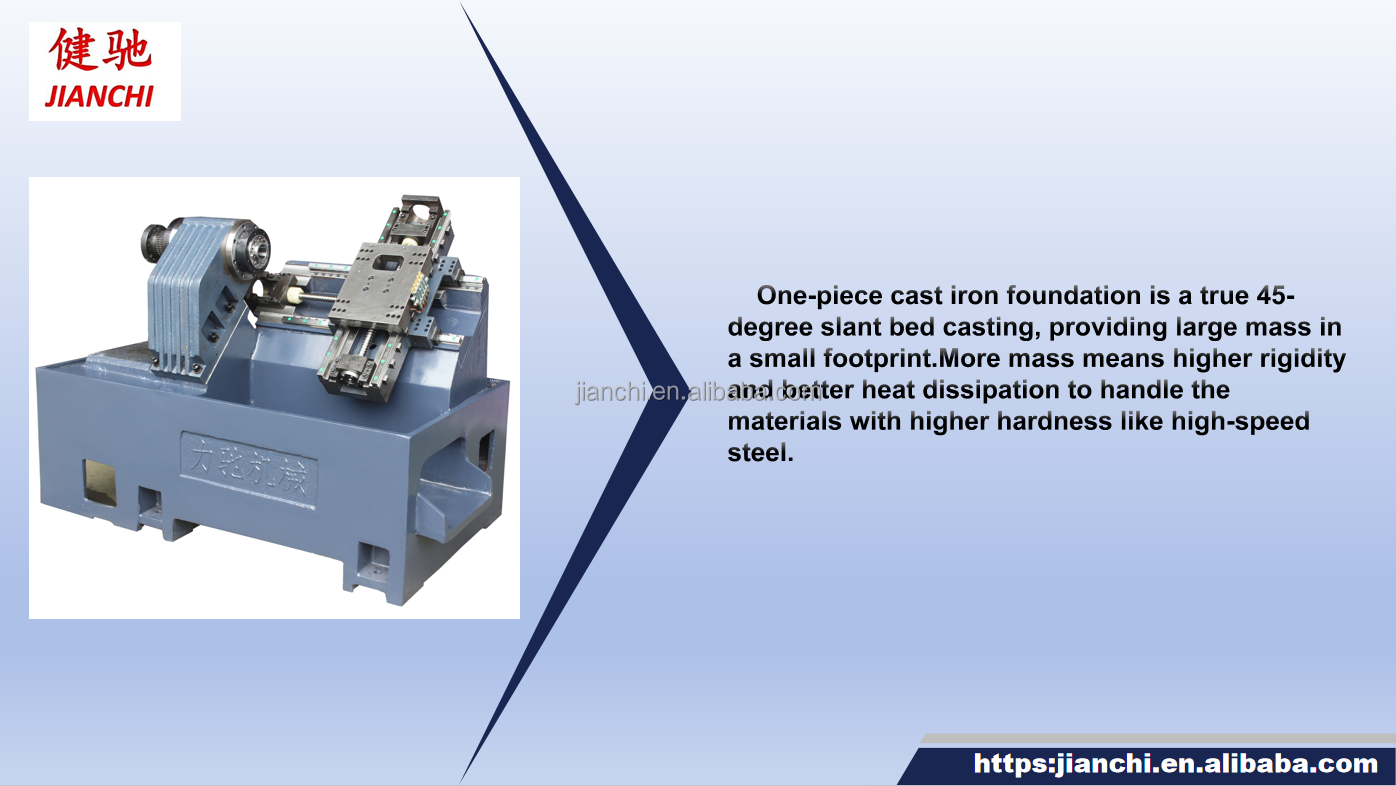

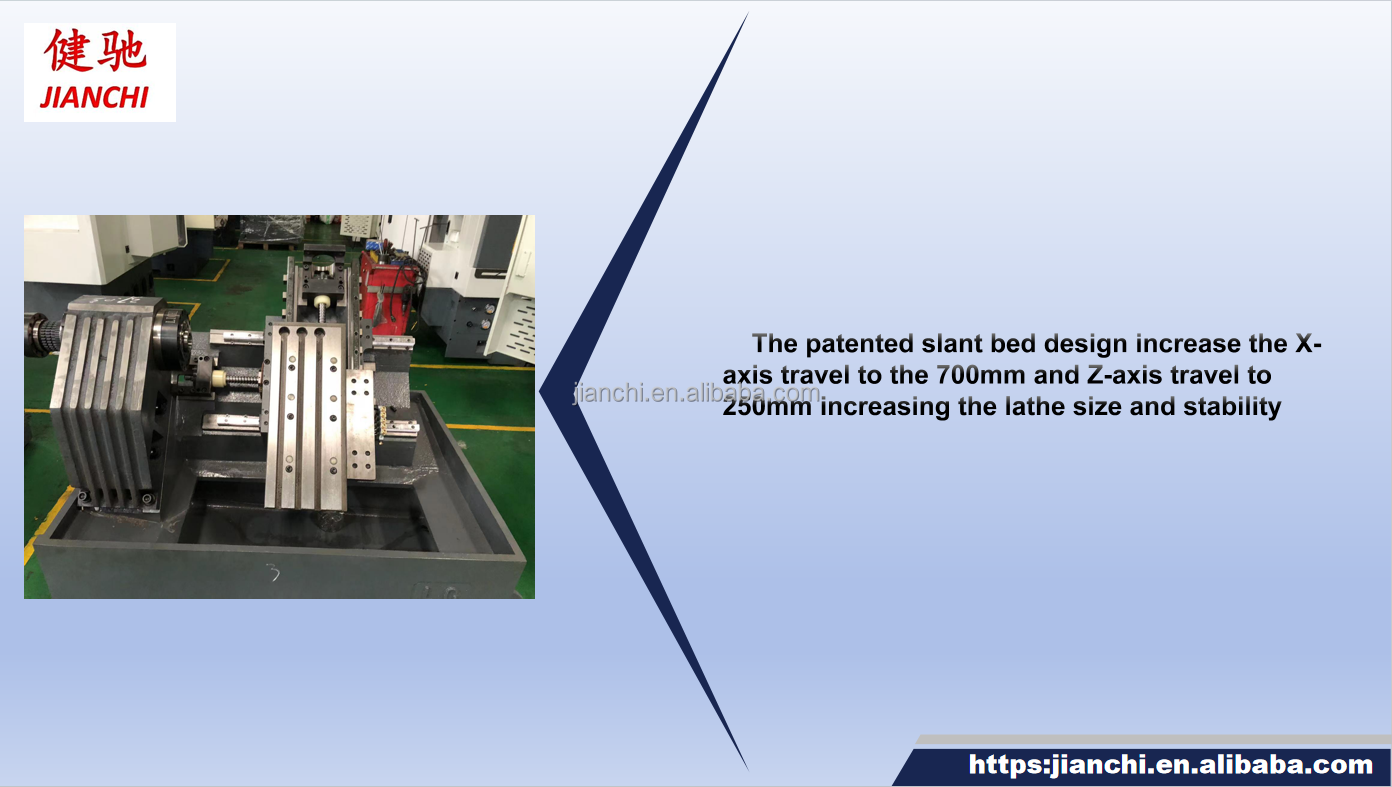

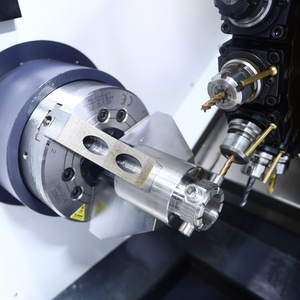

1: 45 ° connected inclined bed casting base. Economical and practical, with exquisite appearance, suitable for precision machining of small parts of various materials in single, small batches, or batches. It can be equipped with auxiliary shafts and automatic up and down mechanisms. Parts processed at both ends can be automatically turned around and formed in one go.

2:Both the X-axis and Z-axis adopt Taiwan roller/ball type 30 linear guides and 5210 high-precision lead screws to enhance the rigidity of the machine tool and improve the precision of the machine tool. With automatic forced lubrication, the high-speed movement of the machine tool can be realized and the positioning accuracy of the machine tool can be guaranteed.