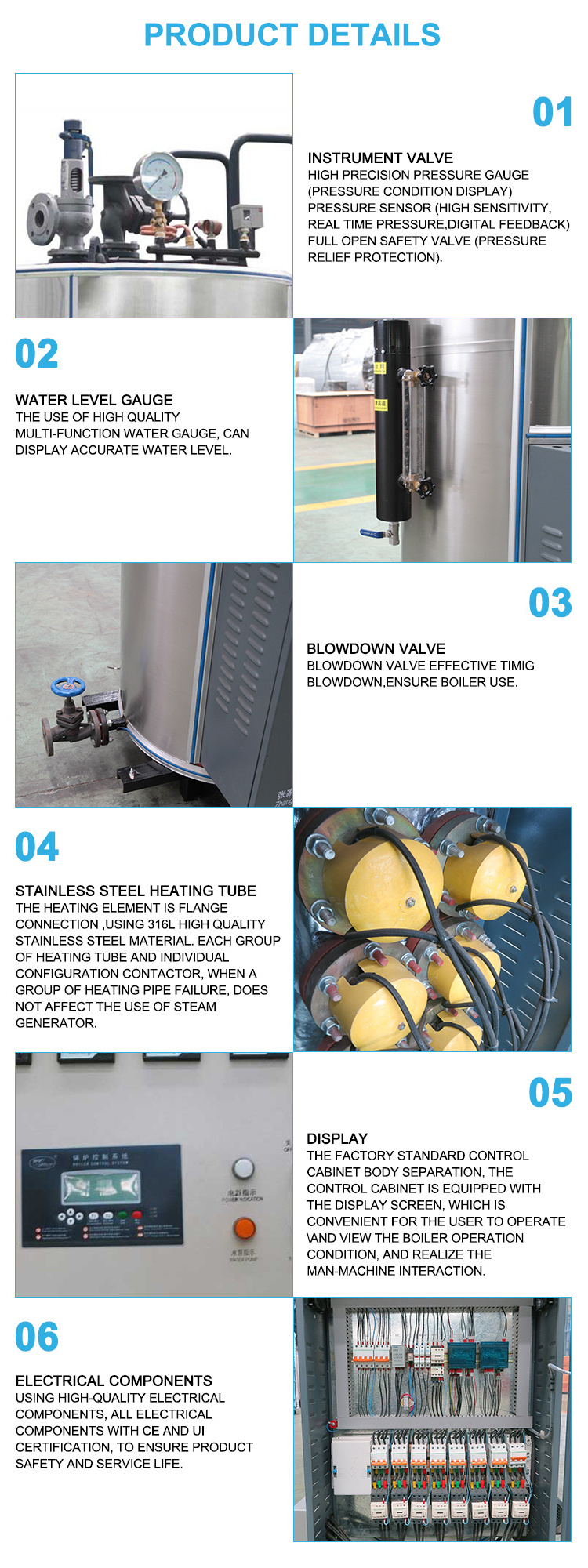

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WILFORD

-

Dimension(L*W*H):

-

Depend

-

Weight:

-

The models are different

-

Rated Voltage:

-

3N AC 50HZ 380V

-

Rated evaporation:

-

0.15-0.5 t/h

-

Rated working pressure:

-

0.7/1.0 or 0.8/1.0 MPa

-

Main steam valve diameter:

-

25-50 DN

-

Safety valve diameter:

-

25-40 DN

-

Inlet diamater:

-

20-25 DN

-

Blowoff Valve diameter:

-

25-40 DN

-

Staturated steam temperature:

-

170/193 or 184/193 ℃

-

Input Power:

-

108-360 KW

-

Certification:

-

ASME,ISO,CE

Quick Details

-

Core Components:

-

Other

-

Steam Production:

-

150-500k/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WILFORD

-

Dimension(L*W*H):

-

Depend

-

Weight:

-

The models are different

-

Rated Voltage:

-

3N AC 50HZ 380V

-

Rated evaporation:

-

0.15-0.5 t/h

-

Rated working pressure:

-

0.7/1.0 or 0.8/1.0 MPa

-

Main steam valve diameter:

-

25-50 DN

-

Safety valve diameter:

-

25-40 DN

-

Inlet diamater:

-

20-25 DN

-

Blowoff Valve diameter:

-

25-40 DN

-

Staturated steam temperature:

-

170/193 or 184/193 ℃

-

Input Power:

-

108-360 KW

-

Certification:

-

ASME,ISO,CE

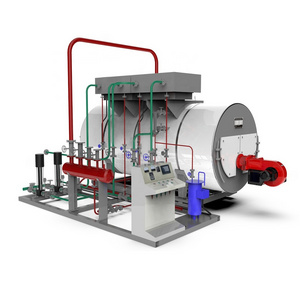

Factory the lowest price electric steam boiler for dry cleaning machine price

Product description

Vertical design electric steam boiler ,the heating elements are completely submerged in water and completely insulated-high efficiency and minimum radiation losses . After precision calculation&design, boiler could quickly and efficiently reach work pressure. Using low heat load surface heating elements-- not easily melted or softened.Each component with water pressure and withstand voltage test.Boiler could immediately work after connecting to power and water supply. Nearly 100% thermal efficiency--quiet, clean, more in line with environmental requirements, No atmospheric emissions NOx (nitrogen oxides)

Technical Parameters

| LDR Vertical Electric Heating Steam Boiler | ||||||

| Type | LDR0.15 | LDR0.2 | LDR0.3 | LDR0.5 | ||

| Project | Unit | |||||

| Rated evaporation | t/h | 0.15 | 0.2 | 0.3 | 0.5 | |

| Rated working pressure | MPa | 0.7/1.0 | 0.7/1.0 | 0.7/1.0 | 0.8/1.0 | |

| Staturated steam temperature | ℃ | 170/184 | 170/184 | 170/184 | 175/184 | |

| Input Power | KW | 108 | 144 | 216 | 360 | |

| Input current | A | 162 | 216 | 324 | 540 | |

| Rated pressure | V | 3N AC 50Hz 380V | ||||

| Power×Group | KW×P | 18×6 | 18×8/24×6 | 27×8 | 36×10 | |

| a Main steam valve diameter | DN | 25 | 25 | 32 | 50 | |

| b Safety valve diameter | DN | 25 | 25 | 25 | 40 | |

| c Inlet diamater | DN | 15 | 15 | 25 | 25 | |

| d Blowoff Valve diameter | DN | 25 | 25 | 40 | 40 | |

| Overall size | L | mm | 1100 | 1150 | 1300 | 1450 |

| W | mm | 950 | 950 | 1100 | 1350 | |

| H | mm | 1950 | 2000 | 2100 | 2300 | |

|

than 300kg/hr ,the structure is seperated --boiler with seperate electrical control cabinet. |

A | mm | - | - | - | 1200 |

| B | mm | - | - | - | 600 | |

| C | mm | - | - | - | 2000 | |

| Weight | kg | 350 | 450 | 680 | 980 | |

Product Advantages

1.All electrical components with CE and UL marks --ensure safety and long life service.

2.Quickly start and stop, big operation load adjusting range,easily handling."

3.Each heating element use a concentrated beam flange connection, independently arrangement, simple structure, high mechanical strength, safe, reliable, convenient replacement, long service life."

4.Flexible working methods, could set either manual or automatic mode."

5.Unique power switching function,could be regulated based on actual demand of steam power, make same usage time/frequency ,improve equipment service life."

6.When electric boiler heating element in a group has problem, could immediate stop operation the destroyed heating group and cut off power supply."

7. Vertical structure, compact and beautiful, elegant style, classic color, save room space and easily installation."

| Please contact here for more product information. | contact us>> |