- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2023

-

Brand Name:

-

Xinjiwang

-

Dimension(L*W*H):

-

1790*1920*1100mm

-

Weight (KG):

-

200

-

Product name:

-

Semi-automatic aluminum tube filling sealing machine

-

Keywords:

-

ointment filling machine

-

MOQ:

-

1 pcs

-

Usage:

-

Used for sealing various aluminum tubes

-

Control:

-

motor

-

Material:

-

SUS 304 316

-

Capacity:

-

10-50tubes/per minuter

-

Advantage:

-

high speed and stable

-

Power:

-

220V or customize

-

Filling volume:

-

25-75 ml, 50-200 ml

Quick Details

-

Production Capacity:

-

30bottles per minuter

-

Automatic Grade:

-

semi automatic

-

Driven Type:

-

electric

-

Voltage:

-

220V

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2023

-

Brand Name:

-

Xinjiwang

-

Dimension(L*W*H):

-

1790*1920*1100mm

-

Weight (KG):

-

200

-

Product name:

-

Semi-automatic aluminum tube filling sealing machine

-

Keywords:

-

ointment filling machine

-

MOQ:

-

1 pcs

-

Usage:

-

Used for sealing various aluminum tubes

-

Control:

-

motor

-

Material:

-

SUS 304 316

-

Capacity:

-

10-50tubes/per minuter

-

Advantage:

-

high speed and stable

-

Power:

-

220V or customize

-

Filling volume:

-

25-75 ml, 50-200 ml

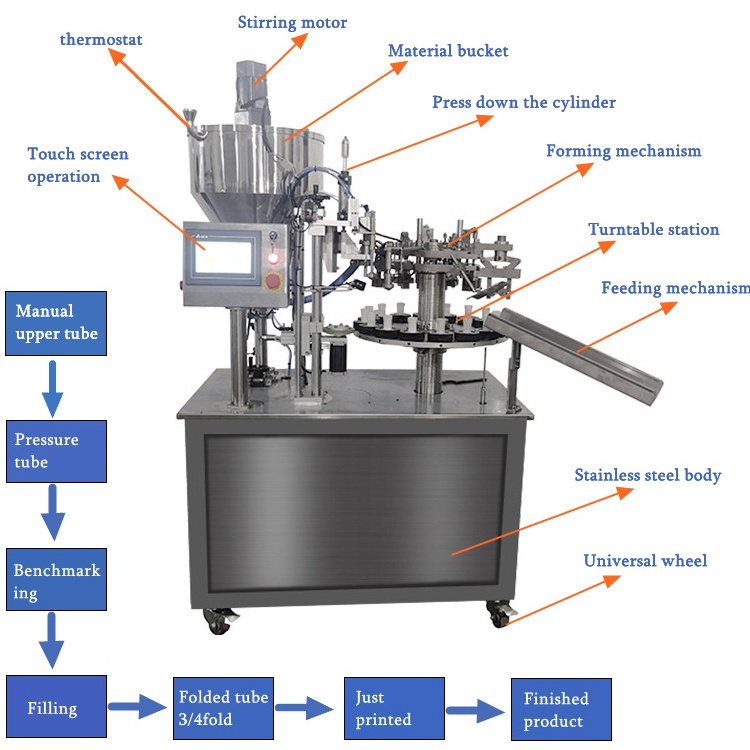

Product Description

Remarks .

Metal aluminum tube filling and sealing machine is mainly used for filling and sealing products with metal aluminum tubes as packaging containers, liquids, ointments and other products, and printing batch numbers at one time. This machine is suitable for daily chemical, and food products, product packaging in chemical and other fields.

Product Paramenters

|

Parameters of aluminum tube filling and sealing machine

|

|

|

|

Filling and sealing speed

|

10~40 pcs/min(Depends on different materials and filling volume)

|

|

|

Filling range

|

15~200ml

|

|

|

Tube height range

|

80~180mm

|

|

|

Pipe diameter (diameter) range

|

20~35mm

|

|

|

Number of stations

|

16pcs

|

|

|

Power

|

1.5 kw

|

|

|

Voltage

|

220V 50HZ 4phase

|

|

|

Weight

|

550KG

|

|

|

Air pressure

|

4~7Mpa

|

|

|

Equipment size

|

1140*600*1580mm

|

|

Main Features

1. The transmission part is enclosed below the platform, which is safe, reliable and pollution-free;

2. The filling and sealing part is installed above the platform for easy observation, operation and maintenance;

3. PLC control, man-machine dialogue interface;

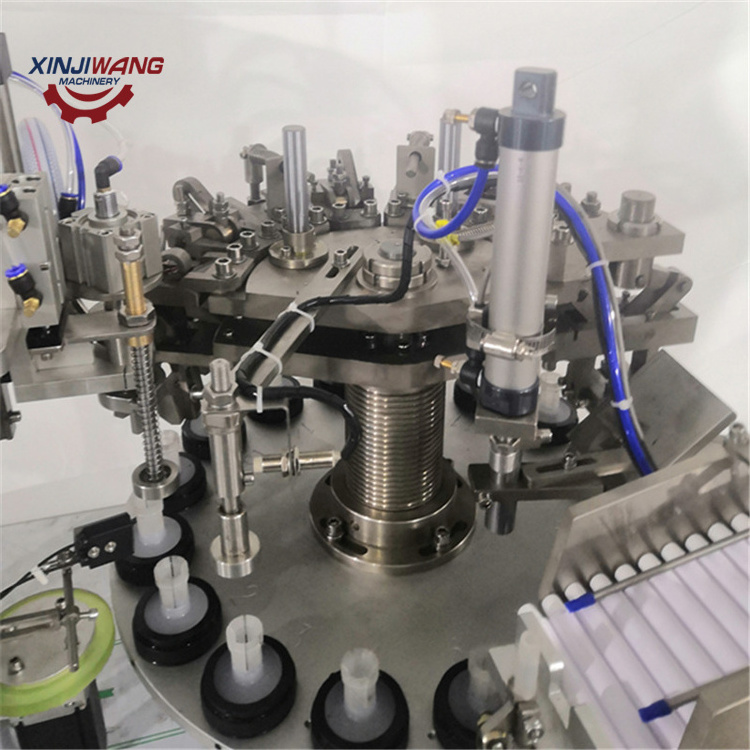

4. The gyro turntable is driven by a cam, with fast speed and high precision;

5. Manually load the tube to ensure accurate entry into the tube seat;

6. The photoelectric benchmarking workstation uses high-precision probes, stepping motors, etc. to control the hose pattern in the correct position

7. The filling nozzle is equipped with a material breaking mechanism to ensure the filling quality;

8. No tube no filling;

9. The internal heating device of the tube tail is adopted for the tail sealing;

10. The typing station automatically prints the character code on the position required by the craft;

11. The plastic manipulator cuts the tail of the hose into right or round corners for selection;

12. Fault protection alarm, no tube alarm, door open shutdown, overload shutdown;

13. Counting and quantitative shutdown

Advantages

1. Imported configuration, easy to use, suitable for food, cosmetics and other different products.

2. Overload protection, phase separation protection, power failure protection.

3. Easy to replace working molds to adapt to different products

4. The equipment is stable and the failure rate is low.

Details Images

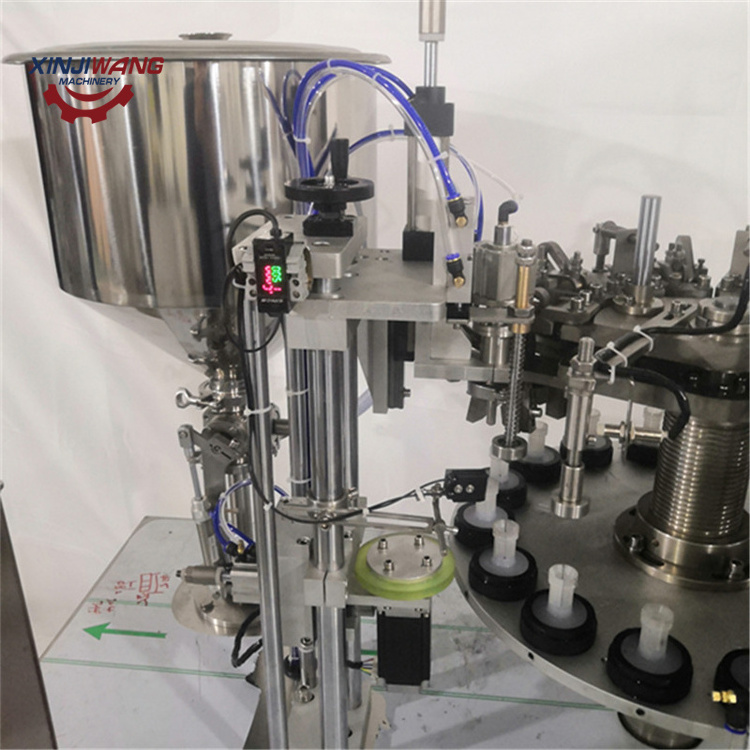

Material hopper

Using food grade stainless steel, large capacity which is in line with GMP hygiene indicators.

Fold tail mechanism

The formed plastic tube is sealed by the sealing module after being filled with liquid.

Filling head

High-precision filling head, anti-drip device, accurate quantitative filling.

Pressure tube station

The automatic benchmarking function can accurately locate the product identification to ensure product consistency.

Automatic benchmarking

Automatic pressure tube, using brand air cylinder to perform action. The pressure and range can be easily adjusted according to product specifications.

Operating station

The touch screen is easy to operate, convenient to modify parameters, and intelligently edit according to different specifications.

Application

Remarks .

The above application product pictures are for reference only, and the actual product size shall prevail.

Our Advantages

1. Installation, debug.

After the equipment reached the workshop of customer and will place the equipment according to layout we offered. Most experienced engineer come overseas to the site for machine installation if you need, just need the fee of round ticket, food and accomodation and the labor cost.

2. Training.

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee.

We promise that our goods are all new and not used. They're made of GMP-food grade material, adopt new design. The quality, specification and function all meet the demand of contract.

.

4. After sales .

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price.One year warranty. Of course, we can provide more years machine quality warranty if you need. JUST to talk with us.

Production Process

Product packaging

FAQ

Q1: Are you factory or trading company?

We are the manufacture factory with high quality machine from Changzhou, Best quality is our principle all the time, so you can be assured on our machine, hope we can offer the best quality and best price machine to you.

Q2:How Can I get a detailed quotation of from you?

Just send us inquiry through this web page is ok or contact me email (), I will reply your any question ASAP, no more than 6

hours.

hours.

Q3:What should I do if we cannot operate the machine when we receive it?

The operation manual and video will be sent along with the machine to give the instructions. And also our engineer will teach you by video call, if it is still not okay, Our engineer can go to customer’s site to solve the problems and train for your staff.

Q4:Do you offer a free set of spare parts on machines?

All spare parts are always avaliable for delivery. We will send extra sets of easy broken spares and accessories, no artificial damaged spare parts would be sent freely during 1 year’s warranty.

Q5: Is there any insurance to guarantee to get the right machine at regular time which I pay ?

You can choose to ge Alibaba trade assurance. Trade assurance provides quality protection, ontime shipment protection and 100% safe payment protection.

Q6: How can I know your machine works well?

Before delivery, we will test the machine to see the working condition and would share the inspection video to you for

confirmation.Or you can inspect the machne to our factory before delivery.

confirmation.Or you can inspect the machne to our factory before delivery.

Q7: What’ s the payment terms and trade terms for customer?

Payment terms 30% advance payment, 70% balance payment before machine inspection is okay.

Semi automatic 502 liquid glue filler and sealer aluminum collapsible tube filling machine for small business

Semi automatic 502 liquid glue filler and sealer aluminum collapsible tube filling machine for small business

Semi automatic 502 liquid glue filler and sealer aluminum collapsible tube filling machine for small business

Hot Searches