- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

Soap making machine

-

Name:

-

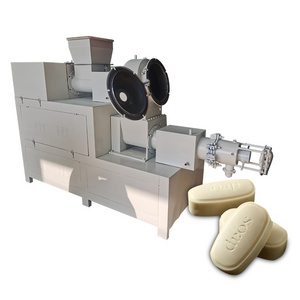

Hotel Soap Production Soap Plodder Making Machine

-

Function:

-

Making Soap

-

Advantage:

-

High quality

-

Color:

-

Clients Request

-

Application:

-

Soap Logo Stamping

-

Capacity:

-

50-2000kg/h

-

PACKING:

-

Wooden Case

-

Keywords:

-

Soap Maker

-

Working method:

-

Electric

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Nora

-

Weight (KG):

-

1000

-

Machine Type:

-

Soap making machine

-

Name:

-

Hotel Soap Production Soap Plodder Making Machine

-

Function:

-

Making Soap

-

Advantage:

-

High quality

-

Color:

-

Clients Request

-

Application:

-

Soap Logo Stamping

-

Capacity:

-

50-2000kg/h

-

PACKING:

-

Wooden Case

-

Keywords:

-

Soap Maker

-

Working method:

-

Electric

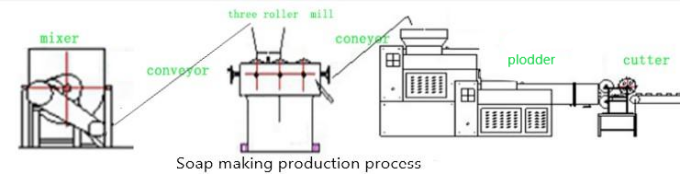

The proiduction line is used for soap making,generally including five part.

1.Mixer.

| Model | M-50 |

| Capacity | 100-500kg/h |

| Weight | 500kg |

| Power | 3 kw |

| Dimension | 18500*1500*1100mm |

Introduction :

The production of soap, transparent soap, a variety of raw materials for a full mix of mixing, so that granulation refinement, all kinds of auxiliary materials and additives

and flavors completely mixed into the granulation, to the formula requirements. Fully mixed soap tablets, soap tablets and a variety of liquid and solid additives can make soap particles and additives fully mixed, stirring effect is full, uniform, color paste, additives completely dissolved into the soap.

2.Three roller mill

Introduction:

It is used for soap refining. Three rolls are horizontally placed with different rotating speeds. The refining function is achieved by pressing and squeezing force between

the adjacent rolls. The main frame is made of high quality stain structure, strong and solid. All gears are precisely manufactured and bathed in oil lubricants for long running life with lower noise, less wearing and better reliability. Rolls are made of special alloy, high hardness, anti-wearing capability.

3.Plodder

Introduction:

The double-single-screw vacuuming machine is composed of two single-linker machines, each with its own independent closed-speed transmission system. The machine is made of precision gears. The screw is made of new aluminum alloy material or high quality stainless steel, which is corrosion resistant and durable. All other parts in contact with the soap are made of high quality stainless steel. The control part can adopt variable frequency or electromagnetic speed regulation, and the production capacity can be adjusted arbitrarily.

4.Cutter or Printer

Block cutter introduction:

This machine can emboss and cut all kinds of toilet soap and laundry soap, fast and accurate. this machine will cut the soap billets from the plodder into long bars to feed into the downstream stamper . This machine uses PLC for accurate control and HMI for easy operation.

Printer introduction:

Stamper adopts the best design and technology, driven by servo control and cam system, reliable and high mechanical repeating accuracy. The suction cups pick up soap billet and put it onto the mould, then after forming, pick finished soap bars out to discharge conveyor. The whole cycle is fully automatic, high speed, low vibration and solid performance.

5.Packaging machine

Packaging machine introduction:

Compact structure, stable performance and easy operation. Double-frequency control, the bag that is set to cut, no need to adjust the air to go, one-stop place, save time and film. Imported appliances, touch-type man-machine interface,quick and easy parameter setting fault diagnosis, fault display at a glance. High sensitivity photoelectric eye color tracking, so that the sealing position more accurate. Temperature independent PID control, better for a variety of materials coated. Positioning stop function, do not stick knife, no film. Rotating system is simple, more reliable work, more convenient maintenance. All control by software to facilitate functional adjustments and technology upgrades, never backward. Suitable for all kinds of product packaging.

Packaging Information

Standard strong export plywood case, pallet for equipment, or as per customer’s requirements.

Delivery Information

About delivery approach

A: By sea or by air, detailed delivery approach could be discussed.

About delivery time

A: Usually it takes about 15-30 working days after we receive your PO cand pre-payment. However, it would depend on our production schedule and the complexity of the equipment.

About trade term

A: Usually we send the equipment in FOB term, however, the CIF is also acceptable, which could be decided by customers

Before installation, the seller will provide the nformation of total line power, individual machine power, power connections, water & air input and output position, total water consumption. After the machines arrival in buyer site and put into position, the buyer must connect the water, electricity, air and vacuum gas with the machines, then the seller shall send 3~4 technicians to help start-up the line for production, on-line training and production supervision. The buyer shall pay below service ratings, as well as round-trip transportation from our factory to buyer’s factory, the visa application fee, food, transportation and accommodation.