- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

less than 1%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tings

-

Dimension(L*W*H):

-

2.8x2.2x2.2m

-

Weight:

-

3500 KG

-

Product name:

-

Bottle Mineral Water Filling Machine Production Line

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304/316

-

Advantage:

-

Easy Operation High Efficiency

-

Filling range:

-

200-2000ml

-

Certification:

-

CE ISO

-

Control:

-

Siemens PLC+ Touch Screen

-

Cap type:

-

Plastic Screw Thread Cap

-

Filling nozzles:

-

14 Nozzles

-

Function:

-

Bottle Washing Filling Capping

Quick Details

-

Machinery Capacity:

-

4000BPH, 3000BPH, 5000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water, Mineral Water

-

Filling Accuracy:

-

less than 1%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Tings

-

Dimension(L*W*H):

-

2.8x2.2x2.2m

-

Weight:

-

3500 KG

-

Product name:

-

Bottle Mineral Water Filling Machine Production Line

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304/316

-

Advantage:

-

Easy Operation High Efficiency

-

Filling range:

-

200-2000ml

-

Certification:

-

CE ISO

-

Control:

-

Siemens PLC+ Touch Screen

-

Cap type:

-

Plastic Screw Thread Cap

-

Filling nozzles:

-

14 Nozzles

-

Function:

-

Bottle Washing Filling Capping

Machine Details

TSGX series Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce PET bottled mineral water, purified water,alcoholic beverage machinery and other non-gas beverage machinery. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.It can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

|

Mineral / Drinking Water Filling Machine

|

|

|

|

Bottle Material:

|

PET Plastic

|

|

|

Bottle Type:

|

PET round or square bottle

|

|

|

Filling Volume :

|

200 - 2000ml

|

|

|

Production Speed:

|

3000BPH-5000BPH

|

|

|

Bottle diameter :

|

50-115mm

|

|

|

Bottle height:

|

160-320mm

|

|

Technical Features:

1.PLC + touch screen control, easy to operate;

2.One-key speed adjustment production is suitable for production at various speeds, which can effectively improve the service life of equipment and meet the needs of expanding production capacity;

3.Self-made polishing and grinding machine for material tanks, polishing and cleaning the inside and outside of material tanks, which can effectively prevent secondary pollution of materials caused by mechanical equipment;

4.All stainless steel materials are made of national standard 304 grade materials, which can effectively improve the anti-corrosion performance of the equipment and prevent the corrosion of the material tank caused by the filling material when the equipment is shut down for more than 2 days.

5.Self-owned CNC machining center ensures machining accuracy, improves equipment operation efficiency, and also ensures the production of spare parts required for lifelong maintenance of equipment;

Machine Details

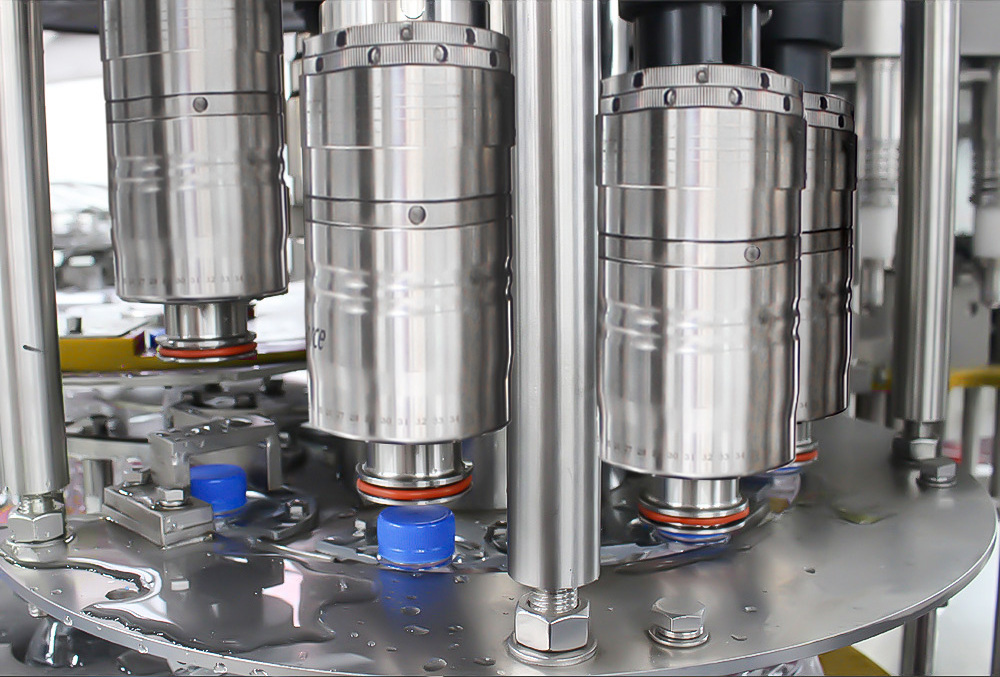

Washing Part

Material: stainless steel 304, nickel not less than 8%

Working way: rotary rinsing

Function: After the PET bottle have been conveyed into the filling machine, rinsing pliers will carry and fix the bottles to the rinsing nozzles. Than after the rinsing of spraying water from the high pressure rinsing nozzles, the bottles are ready to be sent to the filling part.

Filling Part

Material: stainless steel 304, nickel not less than 8%

Function: After the PET bottle have been rinsed, the rotary transmission plate between the rinsing and filling parts will transmit the bottles to the filling part. Then the bottle will be fixed and fully filled precisely in equal volume of water by high pressure spraying filling nozzles. And then the filled bottles will be transmitted to the capping part.

Capping Part

Material: stainless steel 304, nickel not less than 8%

Function: The filled bottles are capped by the rotating capping head. Then the finished products will be conveyed out of the filling machine by the product conveying belt.

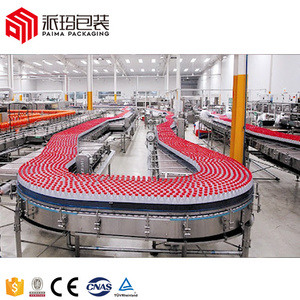

Complete Bottle Mineral Water Filling Production Line

RO Water Treatment System

Water treatment system purify water (Sand filter,carbon filter,RO/UF ,Ozone sterilizer,UV sterilizer and etc.)

Bottle Blowing Machine

Bottle blowing system to make PET plastic bottles ( Semi automatic / Fully automatic )

Bottle Dryer Machine

Material:304 Stainless steel The dryer have two layers with heat resistant material inside. Auto temperature

control

control

Labeling machine

(PVC sleeve labeling machine/OPP hot melt glue labeling machine/Self-adhesive labeling machine)

Code printer

(Ink-jet printer/ laser-jet printer)

Shrink Wrapping Machine

End packaging ( PE film shrink wrapping machine / Carton packing machine )

Hot Searches