- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TANPU

-

Voltage:

-

380V

-

Power:

-

150kw

-

Dimension(L*W*H):

-

other

-

Weight:

-

4500 kg

-

Key words:

-

Laminated Glass Production Line

-

After Warranty Service:

-

1year

-

Brand:

-

TANPU

-

Features:

-

Great Stability

-

Service:

-

After-sales Service Provided

-

Operation:

-

Easy Opearation

-

Advantage:

-

Accept Custom Made

-

Installation:

-

Installation Commissioning

-

Keyword:

-

Stable

-

Package:

-

Wooden Package

Quick Details

-

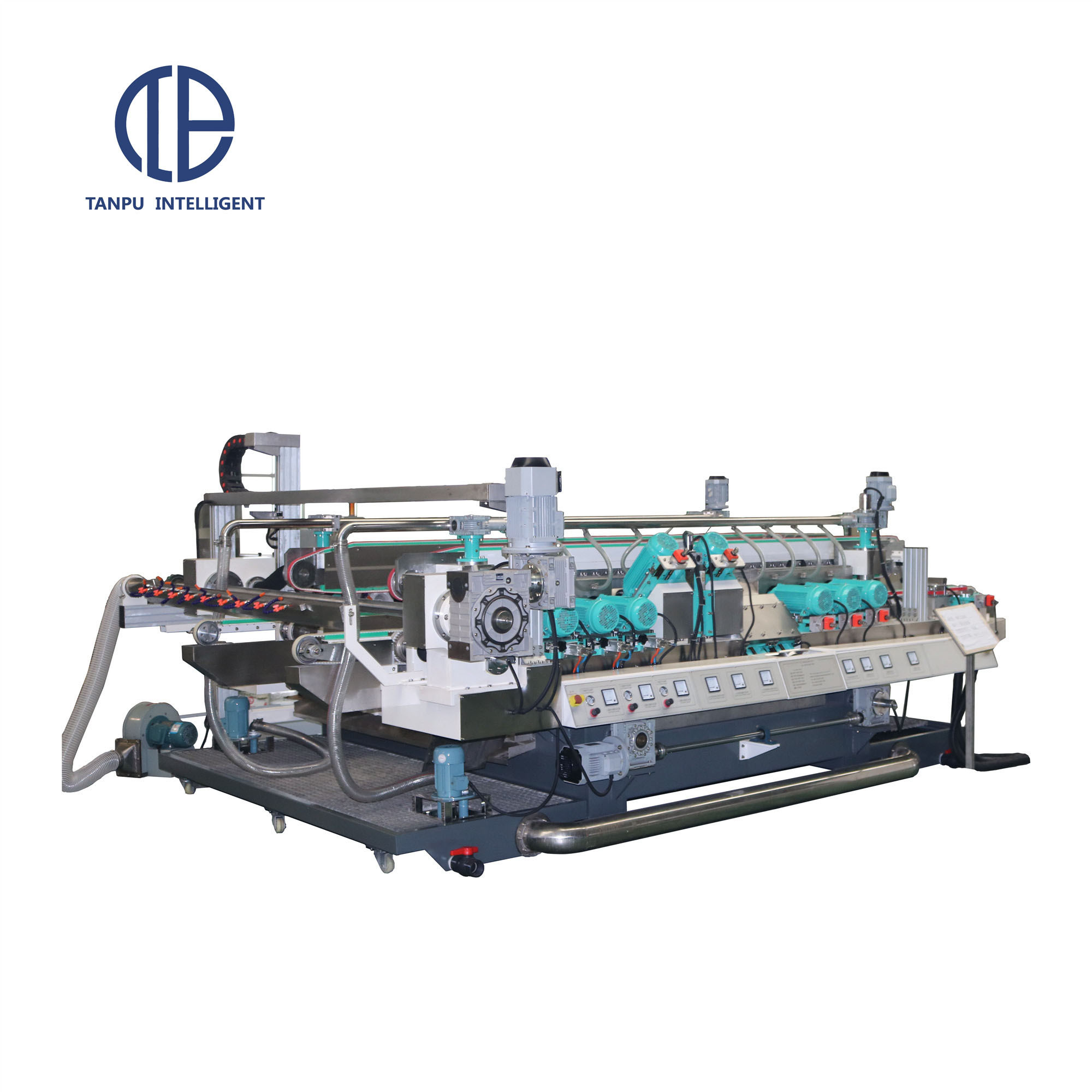

Machine Type:

-

Glass Edging Machine

-

Glass Thickness:

-

4-19mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TANPU

-

Voltage:

-

380V

-

Power:

-

150kw

-

Dimension(L*W*H):

-

other

-

Weight:

-

4500 kg

-

Key words:

-

Laminated Glass Production Line

-

After Warranty Service:

-

1year

-

Brand:

-

TANPU

-

Features:

-

Great Stability

-

Service:

-

After-sales Service Provided

-

Operation:

-

Easy Opearation

-

Advantage:

-

Accept Custom Made

-

Installation:

-

Installation Commissioning

-

Keyword:

-

Stable

-

Package:

-

Wooden Package

|

model

|

glass width

|

machine size

(L*W*H)

|

weight

|

|

TPSB1220

|

160-1200mm

|

5700*3450*1800mm

|

5250kg

|

|

TPSB1620

|

200-1600mm

|

5700*3850*1800mm

|

5650kg

|

|

TPSB2020

|

200-2000mm

|

5700*4250*1800mm

|

6000kg

|

|

TPSB2520

|

200-2500mm

|

5700*4750*1800mm

|

6300kg

|

|

TPSB3020

|

250-3000mm

|

5700*5250*1800mm

|

6600kg

|

|

TPSB3520

|

250-3500mm

|

5700*5750*1800mm

|

6900kg

|

|

TPSB4220

|

280-4200mm

|

5700*6450*1800mm

|

7700kg

|

|

TPSB4520

|

280-4500mm

|

5700*6750*1800mm

|

8300kg

|

|

glass thickness for process

|

3-25mm

|

parallel tolerance

|

≤0.2mm

|

|

chamfer tolerance

|

≤0.2mm/m

|

diagonal tolerance

|

≤0.4mm/m

|

|

Item

|

Designation (Depending on the specific product configuration)

|

Brand

|

|

1

|

PLC

|

SCHNEIDER/OMRON/MISUBISHI

|

|

2

|

Touch screen

|

Schneider/HITECH/WEILUNTONG

|

|

3

|

Inverter

|

Schneider/OMRON

|

|

4

|

Contactor

|

Schneider/TE

|

|

5

|

Linea guideway

|

Taiwan HIWIN

|

|

6

|

Ball screw

|

ABBA Taiwan ABBA

|

|

7

|

Synchronous belt

|

KEXIN

|

|

8

|

Extended module

|

Schneider/OMRON

|

|

9

|

Motor breaker

|

Schneider/LS

|

|

10

|

Encoder

|

Schneider/OMRON

|

|

11

|

Intermediate replay

|

Schneider

|

|

Main Function

|

|

|

|

|

||||

|

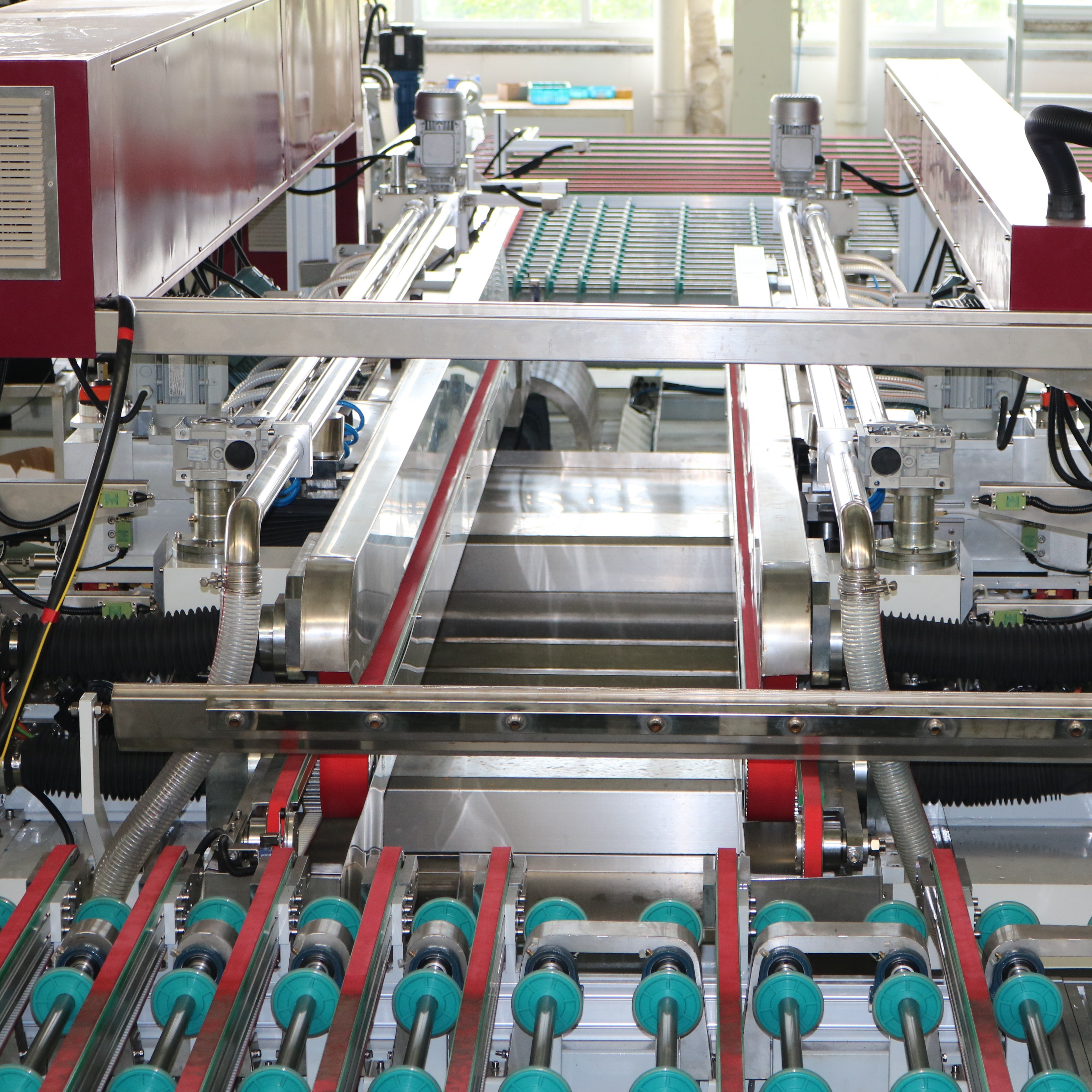

1,The two synchronized belt transfer the glass into the grinding position

|

|

|

|

|

||||

|

2,The machine exist a correction mechanism is performed by touch screen to make sure the glass edge paralell and 90 degree angle

|

|

|

|

|

||||

|

3,Glass powder and also the heat generated by grinding can be released by ressure water from the water pump, water can also affect

for lubircant for the whole working process; |

|

|

|

|

||||

|

4,Grinding wheels consisit of corse grinding,fine-grinding, polishing, fine polishing,top&bottom 45 degree and corner dubbting

|

|

|

|

|

||||

|

5,Polishing wheel adopt air compensation pnumatic control for griding status,the air control can also do following up grinding based

on wheels consuming. |

|

|

|

|

||||

|

6,A air blade is configured on the unloading side of the machine which can dry up the water on glass. There is also a water spraying

system to clear out the glass powder from the glass and also for protecting the synchronized belt for better performing without affection fromg glass powder |

|

|

|

|

||||

|

Technical Feature

|

|

|

|

|

||||

|

1,Machine mechanic frame were completed by using high quality steel square bar at 300mm x 200mm x 10mm, whole mechanizm also adopt relief annealing plus no stress milling process, the machine base can never be shaped, and the machine fabrication quality highly assured. Machine mechanic base with closing and opening adopt double leading screww,and double linear guide, the accuracy can be assured at ±0.1mm

|

|

|

|

|

||||

|

2,Upper and bottom press beam adopt high precision seamless sychronized belt and wheel, which assure the transfer accuracy in high performing.Less friction containes between the upper and bottom beam,leading screw groove is with high anti-consumption material, which can reduce down the consumption, and highly improve stability and life span of the leading rail. In order to assure the acending and descending accuracy, elevator machanizm adopt trapozoid screw.To ensure a balanced power for holding small piece of glass, upper press bar adopt silding embeded mode, which also facilitate the replacing of the wheels, upper press beam can raise up to 150mm

|

|

|

|

|

||||

|

3,To avoid scratches on the glass, the machine feeding section use signal collection from side direction.Thickness of the sychronized belt adopt 4mm more high quality rubber.A cleaning system is adopted for the machine sychronized belt.

|

|

|

|

|

||||

|

4.For a better maintenance for the machine to replace upper and bottom sychronized belt, and also for avoiding rusted on the main driving shaft, a separation design between shaft and driving belt is added on this machine

|

|

|

|

|

||||

|

5.Whole machine adopt 2 sets of automatic self-lubricating pump with PLC control, which greatly save the labor power. For a better life span, the machine adopt stainless steel materal among the section that touches the water during process.(includegriding wheel water tank and also middle water tank), Alumnium alloy parts and also chorme plated spare parts, stainless steel 304 shaft material

|

|

|

|

|

||||

|

6,In order to avoid danger for motor falling down,45 degree grinding motor adopt separation design and assembling.

|

|

|

|

|

||||

|

7,For assuring the same grinding quality durng consuming of grinding wheels and also interruption of human adjustment, an air compensation pnumatic system mechanizm were adopt. Polishing speed can be in 4 meters/Min. Note: if the request on edging is high,the polishing speed will be reduced down accordingly.

The production line use X and Y linkage follow up plus Grade 2 buffering mechanizm, range of chamfer edging can be adjustable at 1.5mm~3mm, speed can of chamfer edging can be at 6 meters/min(speed can goes up and down based on glass thickness). bottom edging will always assure equal.

|

|

|

|

|

||||

|

Technical Protocol

|

|

|

|

Height of platform

|

920±20mm

|

|

|

Glass Width

|

280mm-4200mm

|

|

|

Glass thickness

|

3-25mm

|

|

|

Parallel tolerance

|

≤0.2mm

|

|

|

Transmission speed

|

0.5-8m/min

|

|

|

Diagonal tolerance (mm/mm)

|

≤0.8/2000

|

|

|

Overall Dimension

|

5330mm x 6450mm x 1800mm

|

|

|

Total power

|

52.94KW

|

|

|

Weight

|

7700KG

|

|

|

Compressed Air

|

6KG/CM2

|

|

1.Who are we?

TANPU INTELLIGENT is a design and fabrication oriented company for Flat Glass Deep processing technology. We are based on Guangdong, China, start from 2015, sell to Eastern Europe(30.00%), South America(20.00%), Southeast Asia(20.00%), North America(10.00%), Mid East(10.00%), Southern Europe(10.00%). There are total about 5-10 people in our office.

2.When can we arrange shipment?

We usually arrange shipment within 30 days after getting deposit, but customized machines should be between 60~100 days.

3.How to provide after-sales service?

Free warranty for one year. Provide remote services and video guidance.

4.What operating language is the machine?

Standard English, can also be changed as required

5.How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us for engineer

dispatching.

6.How can I contact you?

You can contact us directly on Ali International platform or add WA:008613703234074 or yt-machinery@vip.163.com.

7.Can l have a sample?

Yes, we can provide you with samples, but you need to pay the price of individual samples.

TANPU INTELLIGENT is a design and fabrication oriented company for Flat Glass Deep processing technology. We are based on Guangdong, China, start from 2015, sell to Eastern Europe(30.00%), South America(20.00%), Southeast Asia(20.00%), North America(10.00%), Mid East(10.00%), Southern Europe(10.00%). There are total about 5-10 people in our office.

2.When can we arrange shipment?

We usually arrange shipment within 30 days after getting deposit, but customized machines should be between 60~100 days.

3.How to provide after-sales service?

Free warranty for one year. Provide remote services and video guidance.

4.What operating language is the machine?

Standard English, can also be changed as required

5.How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us for engineer

dispatching.

6.How can I contact you?

You can contact us directly on Ali International platform or add WA:008613703234074 or yt-machinery@vip.163.com.

7.Can l have a sample?

Yes, we can provide you with samples, but you need to pay the price of individual samples.

Hot Searches