- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Songbai

-

Voltage:

-

220V

-

Motor Power (Kw):

-

7.5kw

-

Power (kW):

-

4

-

Weight (KG):

-

78 KG

-

Name:

-

Wood Pellet Making Machine

-

Application:

-

Make Biomass Pellets

-

After-sales Service Provided:

-

Service Machinery Overseas

-

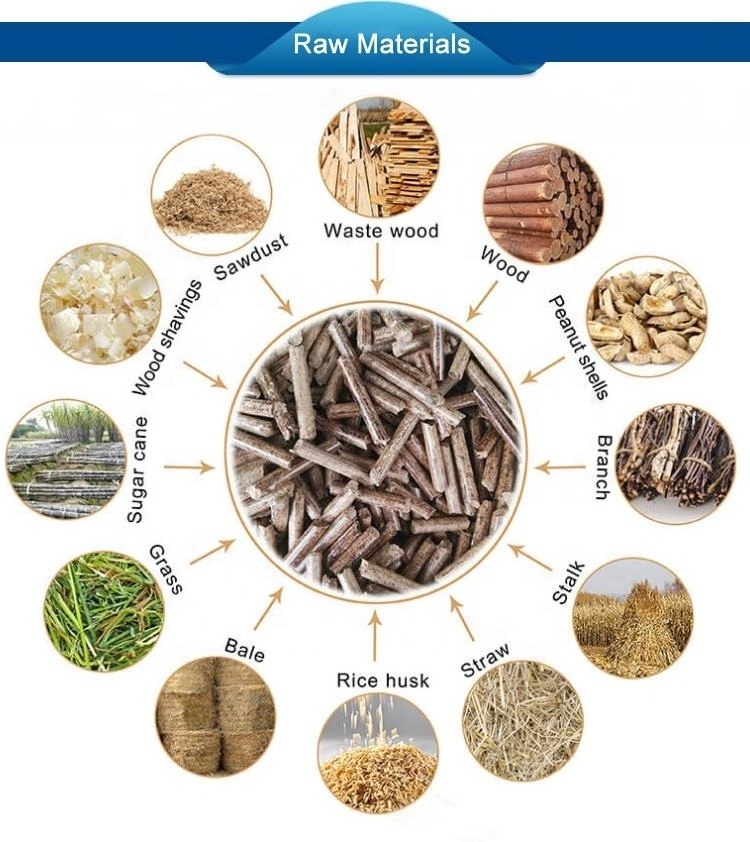

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Production Line Machines Pellet

-

Capacity:

-

100-3000kg/h

-

Pellet size:

-

6/8/10/12mm

-

Function:

-

Biomass Fuel Pellet Production Machine

-

Advantage:

-

High Performance

-

Certification:

-

CE ISO

Quick Details

-

Pellet Diameter (mm):

-

2 - 10

-

Output (kg/h):

-

500 - 1000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Songbai

-

Voltage:

-

220V

-

Motor Power (Kw):

-

7.5kw

-

Power (kW):

-

4

-

Weight (KG):

-

78 KG

-

Name:

-

Wood Pellet Making Machine

-

Application:

-

Make Biomass Pellets

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Production Line Machines Pellet

-

Capacity:

-

100-3000kg/h

-

Pellet size:

-

6/8/10/12mm

-

Function:

-

Biomass Fuel Pellet Production Machine

-

Advantage:

-

High Performance

-

Certification:

-

CE ISO

Product description

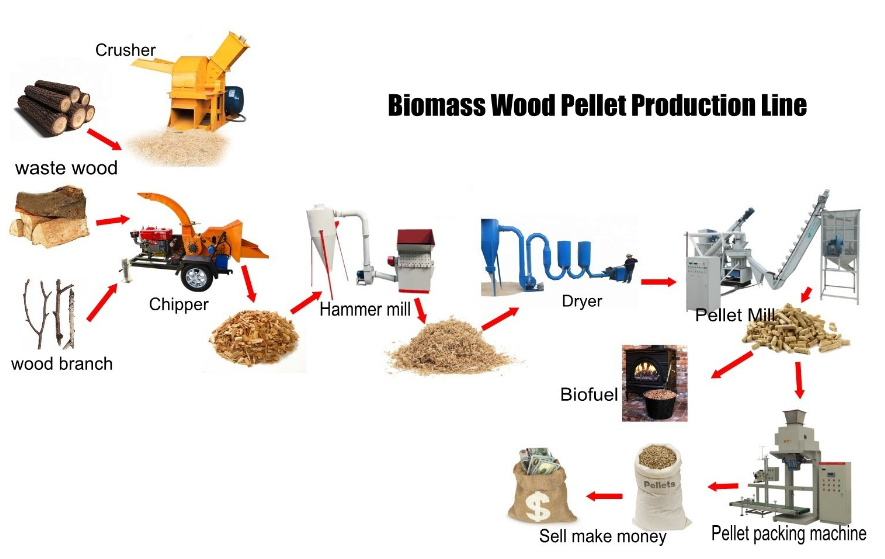

The Development Prospect Of The Wood Pellets Production

Every year millions tons of Agricultural / Biomass waste are generated. These are either non used or burnt inefficiently in their loose form causing air pollution. Now we provide the solution to convert this wastage into best form. These wastage can easily convert into high density fuel (briquettes) with the help of Pellet Mill.

Every year millions tons of Agricultural / Biomass waste are generated. These are either non used or burnt inefficiently in their loose form causing air pollution. Now we provide the solution to convert this wastage into best form. These wastage can easily convert into high density fuel (briquettes) with the help of Pellet Mill.

Technical Parameters

|

Model

|

Capacity (kg/h)

|

Power

(kw)

|

Pellet Diameter

(mm)

|

Weight

(kg)

|

Machine Size

(mm)

|

|

PM-S-200

|

100-150

|

7.5

|

3-12mm

|

230

|

1000*450*850

|

|

PM-S-250

|

200-250

|

15

|

3-12mm

|

350

|

1200*550*1050

|

|

PM-S-300

|

250-350

|

22

|

3-12mm

|

450

|

1250*600*1100

|

|

PM-S-400

|

400-500

|

30

|

3-12mm

|

780

|

1400*600*1200

|

|

PM-S-500

|

700-800

|

55

|

3-12mm

|

1300

|

1700*750*1450

|

|

PM-S-600

|

1200-1300

|

90

|

3-12mm

|

1800

|

2100*900*1650

|

|

PM-S-700

|

1700-1800

|

132

|

3-12mm

|

2300

|

2400*1050*1870

|

Product Advantages

1.We produce the wood pellet making machine in accordance with the European standard.

2. All of our machines have passed CE certificate.

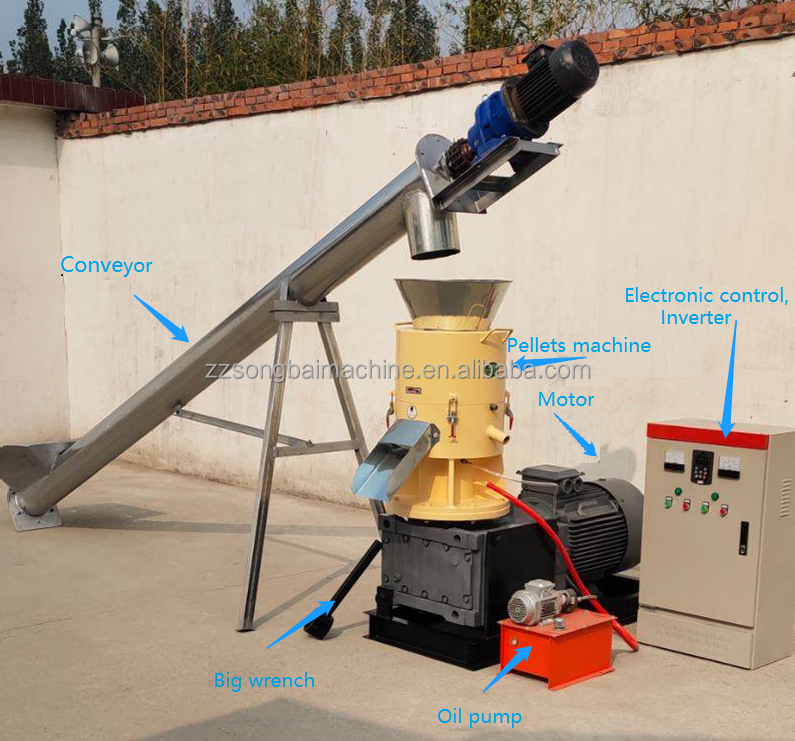

3.Our flat die type wood pellet machine is for pressing biomass materials to be solid pellets which are used for burning.

4.You can use nearly all kinds of biomass as raw materials, such as agricultural waste, straw, fodder, forestry wastes, lumber, leftover, sawdust, wood chips and so on.

5. As for the power, you can choose diesel engine driven or electric motor driven. And we have many different models for your option.

6.Our pellet machines are ideal pellet press for personal, family and small plants. It’s very easy to operate and maintain.

2. All of our machines have passed CE certificate.

3.Our flat die type wood pellet machine is for pressing biomass materials to be solid pellets which are used for burning.

4.You can use nearly all kinds of biomass as raw materials, such as agricultural waste, straw, fodder, forestry wastes, lumber, leftover, sawdust, wood chips and so on.

5. As for the power, you can choose diesel engine driven or electric motor driven. And we have many different models for your option.

6.Our pellet machines are ideal pellet press for personal, family and small plants. It’s very easy to operate and maintain.

Product Application

Small Biomass Pellet Mill Wood Pellets Making Machine Instruction

Mainly used for home and small process plant, It is mainly used for Wood, Straw, Cotton stalk, Rice husk, Peanut shell, Bamboo, Empty fruit branch, Pulverized coal and waste paper etc. Advantages of out products is high density, high fuel value, low moisture and low ash content, machines running by reduction gears. Details, as follows:

Mainly used for home and small process plant, It is mainly used for Wood, Straw, Cotton stalk, Rice husk, Peanut shell, Bamboo, Empty fruit branch, Pulverized coal and waste paper etc. Advantages of out products is high density, high fuel value, low moisture and low ash content, machines running by reduction gears. Details, as follows:

The Industrial (Commercial) Used of Wood Pellets Making Machine

Suitable used for the small pellet production line or industrial pellet plant.

Suitable used for the small pellet production line or industrial pellet plant.

About us

Zhengzhou Songbai Machinery Co. Ltd

is devoted to offer biomass pellet machine series , carbonization furmace series, mobile gas heater, organic ferizer production series, and animal feed productione series. We can provide various solutions for different raw materials, which can meet the market demands. We had passed the IS09001 quality system and got the CE certification for all of our machines.

Packing & Delivery

FAQ

1.Could I have prices of your products?

Welcome. Please feel free to send us an email here. You will get our reply in 24 hours

2.How much the Courier freight will be for the samples?

Courier freight depends on the quantity,weight and carton size and your area.

3. How about the package?

Net weight: as the customers' requirement.

4. How does your factory do regarding quality control?

My company always attaches great importance to quality controlling from the very beginning to the very end.

5. How about your delivery time?

Generally, it will take 7 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Courier freight depends on the quantity,weight and carton size and your area.

3. How about the package?

Net weight: as the customers' requirement.

4. How does your factory do regarding quality control?

My company always attaches great importance to quality controlling from the very beginning to the very end.

5. How about your delivery time?

Generally, it will take 7 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Hot Searches