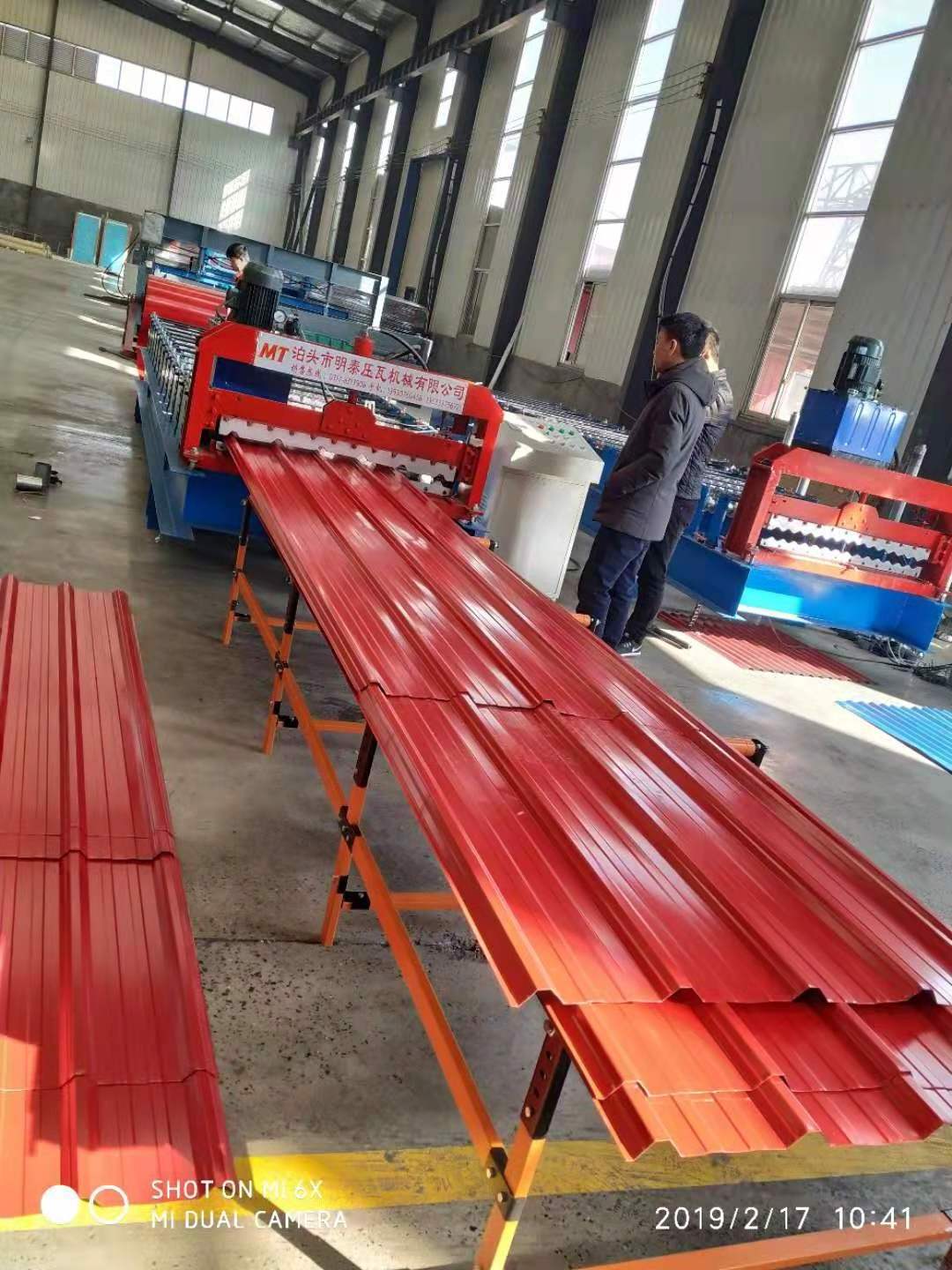

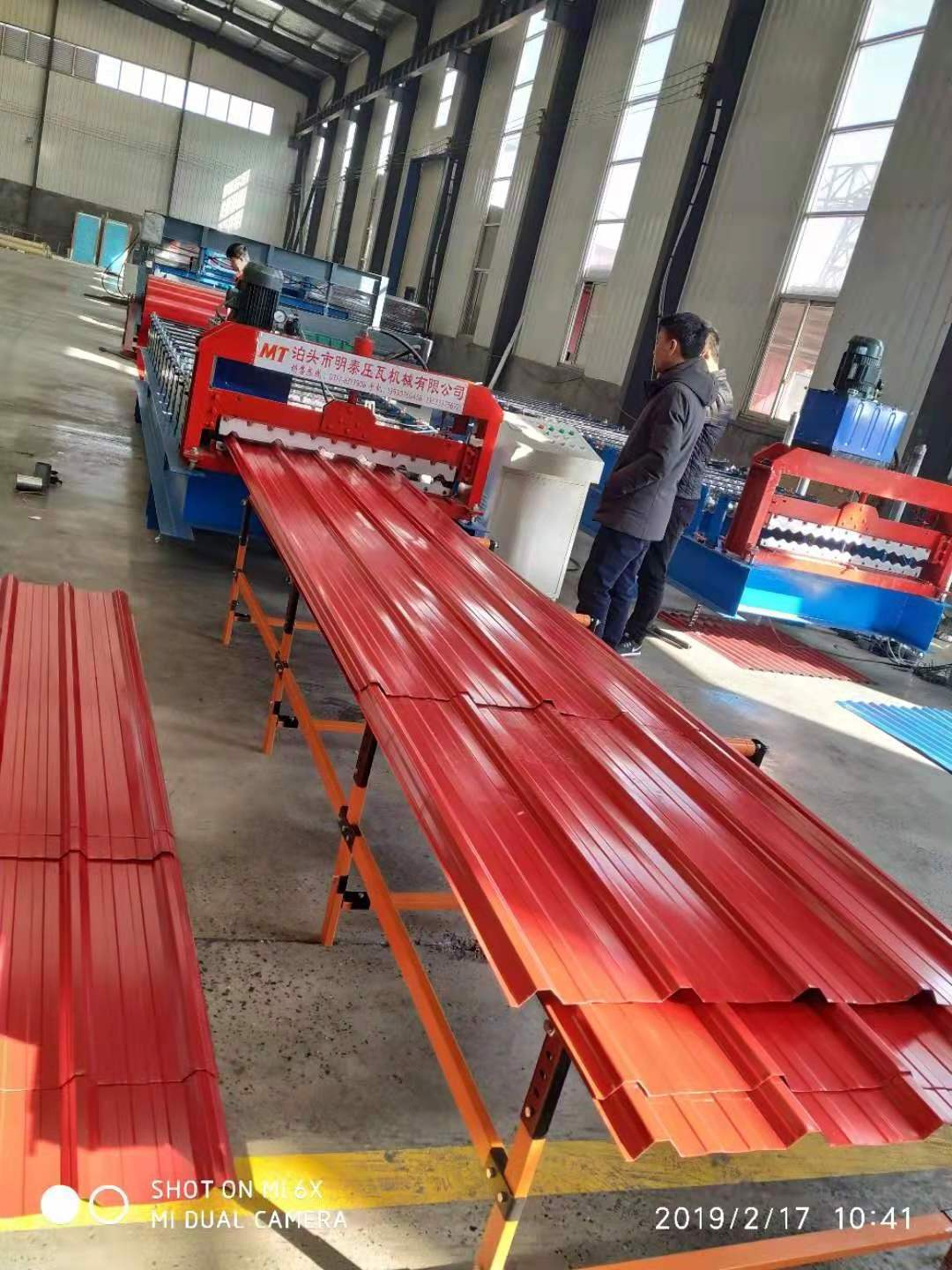

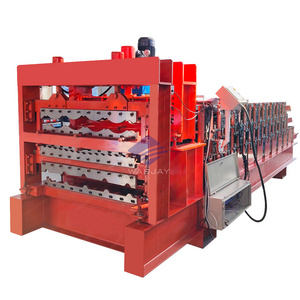

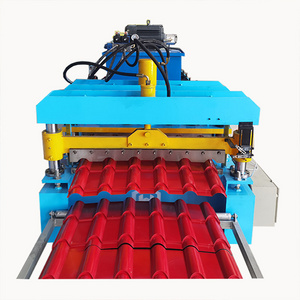

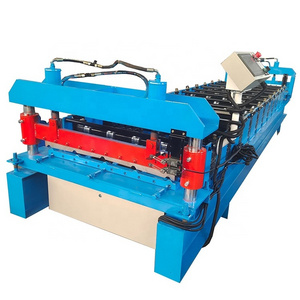

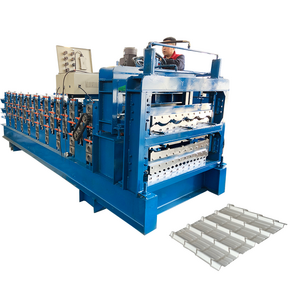

2.The machine is stable,no noise,no shake.

3.Controlling by computer,PLC display,operation is easy,running is steady and reliable,endurable,maintenance-free.

4.Cutting machine is characterized by stable driving,easy operation.

5.Hydraulic system use the hydraulic pump,long operating life,no noise.