- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LN

-

Dimension(L*W*H):

-

550mm x 330mmx 320mm

-

Weight:

-

45 KG

-

Max. Heating Temp:

-

200°C

-

Temperature controller accuracy:

-

+/-1°C

-

Accessories:

-

Optional 50 upto 250 mm width micrometer adjustable film applicator

-

Platform:

-

Aluminum alloy flat vacuum chuck

-

Traverse Speed:

-

0 - 120 mm/sec variable

-

Traverse Speed Accuracy:

-

10mm/sec

-

Stroke Length:

-

Opitional

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

Quick Details

-

Applicable Industries:

-

battery

-

Core Components:

-

coater

-

Voltage:

-

500-1500W

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LN

-

Dimension(L*W*H):

-

550mm x 330mmx 320mm

-

Weight:

-

45 KG

-

Max. Heating Temp:

-

200°C

-

Temperature controller accuracy:

-

+/-1°C

-

Accessories:

-

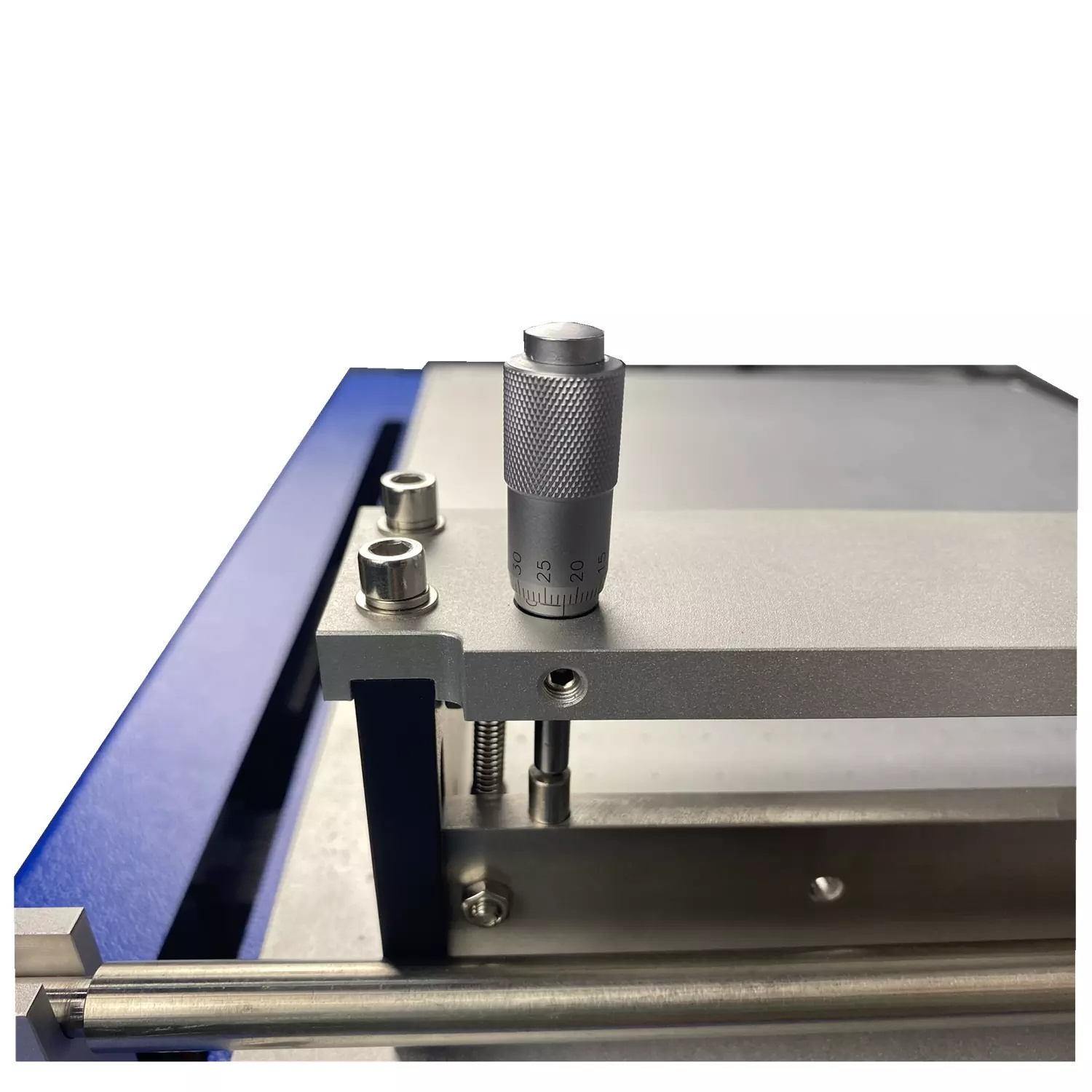

Optional 50 upto 250 mm width micrometer adjustable film applicator

-

Platform:

-

Aluminum alloy flat vacuum chuck

-

Traverse Speed:

-

0 - 120 mm/sec variable

-

Traverse Speed Accuracy:

-

10mm/sec

-

Stroke Length:

-

Opitional

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

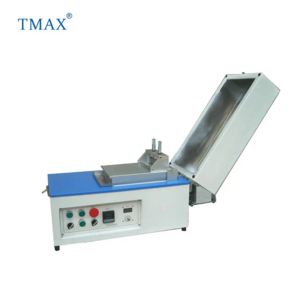

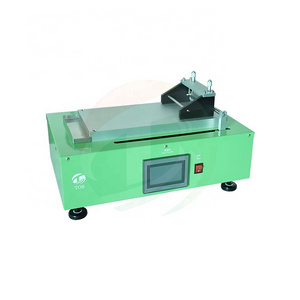

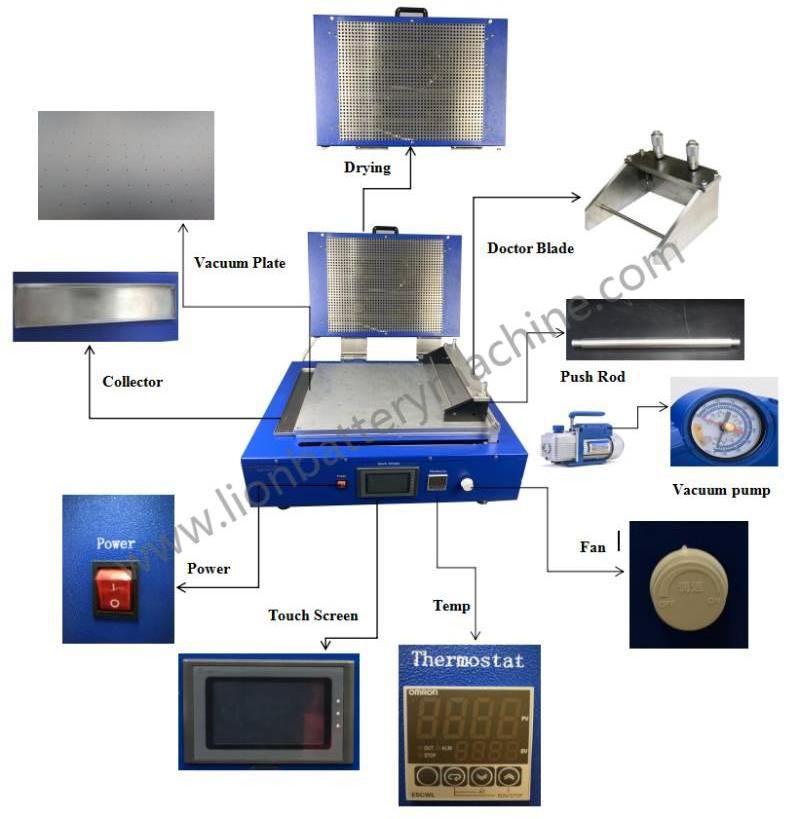

Lab Adjustable Film Applicator Coating Machine With Heating Function And Vacuum Chuck

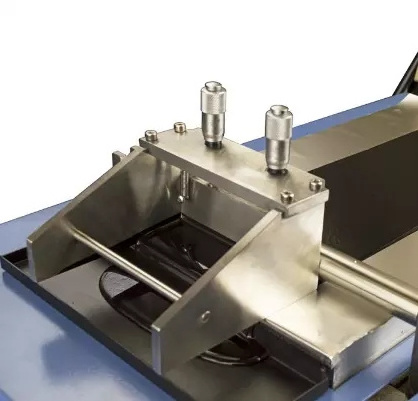

LN-TMH is a CE Certified ready compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin coatings. There is a 100 mm width adjustable micrometer applicator (doctor-blade).

Heating cover with digital temperature controller can dry films after coating up to 100°C with a temperature accuracy of +/-1°C.

This equipment can be used for researchers on ceramic tape castings and Li-Ion battery electrode coating.

Heating cover with digital temperature controller can dry films after coating up to 100°C with a temperature accuracy of +/-1°C.

This equipment can be used for researchers on ceramic tape castings and Li-Ion battery electrode coating.

|

Model

|

100-250

|

150-250

|

250-300

|

250-350

|

250-500

|

250-800

|

|||||

|

Effective coating

area(mm, size can be customized) |

100 x 250

|

150 x 250

|

250 x 300

|

250 x 350

|

250 x 500

|

250 x 800

|

|||||

|

Stroke length

(mm, length adjustable) |

10 - 250

|

10 - 250

|

10 - 300

|

10 - 350

|

10 - 550

|

10 - 800

|

|||||

|

Vacuum chuck

dimensions (mm, W*L, , size can be customized) |

100 x 365

|

150 x 365

|

250 x 400

|

250 x 450

|

250 x 650

|

250 x 900

|

|||||

|

Power supply

|

110VAC or 220VAC

|

|

|

|

|

|

|||||

|

Coating speed

|

0 - 120 mm/sec variable; accuracy: 10mm/sec

(The coating speed range can be customized) |

|

|

|

|

|

|||||

|

Vacuum pump

(Optional) |

One oil free vacuum pump

Pumping rate: 60 Hz:1.8 CFM, 50 L/min Extreme vacuum: 5 Pa, 375 microns |

|

|

|

|

|

|||||

|

Film applicator

|

One standard film applicator is included as below:

*Analog film applicator with fix coating width *0~3mm gap/coating thickness adjustable *Coating accuracy: ±3μm |

|

|

|

|

|

|||||

|

|

Optional parts:

Digital micrometer Adjustable width Different gap/coating thickness |

|

|

|

|

|

|||||

|

Heating function

(selectable) |

Platen heating(standard)

1. Heating on the vacuum chuck/coating plate 2. Built in digital temperature controller with accuracy of +/-1°C 3. Max. Heating Temp: 120°C 4. You can choose to have the cover or not, with cover, it will faster the drying speed as it will keep the |

|

|

|

|

|

|||||

|

|

Top cover heating

1. Heater pre-installed on the top cover 2. Built in digital temperature controller with accuracy of +/-1°C 3. Suspension support helps open cover easily and safely 4. Max. Heating Temp: 200°C |

|

|

|

|

|

|||||

|

Surface finish

|

▽10

|

|

|

|

|

|

|||||

|

Surface roughness

|

Ra0.1

|

|

|

|

|

|

|||||

|

Vacuum board

material |

5052 Aluminum alloy

|

|

|

|

|

|

|||||

|

Compliance

|

CE Certificate

|

|

|

|

|

|

|||||

|

Warranty

|

One year limited warranty with lifetime support

|

|

|

|

|

|

|||||

Hot Searches