- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

0.75

-

Range of Spindle Speed(r.p.m):

-

5 - 400 r.p.m

-

Place of Origin:

-

China (Mainland)

-

Brand Name:

-

MITR

-

Voltage:

-

220V 50HZ

-

Dimension(L*W*H):

-

71*49*63cm

-

Weight (KG):

-

98 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

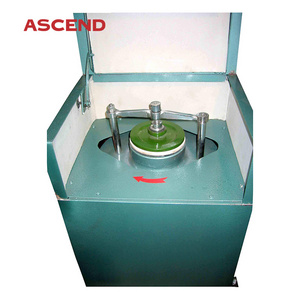

Battery Research Ultra Fine Grinding Mill For Laboratory Pulverizer

-

Feeding granularity:

-

Soil material≤10mm,others ≤3mm

-

Discharging granularity:

-

minimum down to 0.1μm

-

Max revolution:

-

5-400rmin

-

Rotation:

-

10-800rmin

-

Working mode:

-

Four jars working at the same time

-

Transmission mode:

-

Gear drive,motor direct connection

-

Grinding jar volume(ml):

-

50-500ml

-

Max continue time:

-

72H(Timing 0-9999h)

Quick Details

-

Output (kg/h):

-

1 - 10 kg/h

-

Feeding Size (mm):

-

3 - 5 mm

-

Output Size (mesh):

-

1000 - 10000 mesh

-

Power (kW):

-

0.75

-

Range of Spindle Speed(r.p.m):

-

5 - 400 r.p.m

-

Place of Origin:

-

China (Mainland)

-

Brand Name:

-

MITR

-

Voltage:

-

220V 50HZ

-

Dimension(L*W*H):

-

71*49*63cm

-

Weight (KG):

-

98 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Battery Research Ultra Fine Grinding Mill For Laboratory Pulverizer

-

Feeding granularity:

-

Soil material≤10mm,others ≤3mm

-

Discharging granularity:

-

minimum down to 0.1μm

-

Max revolution:

-

5-400rmin

-

Rotation:

-

10-800rmin

-

Working mode:

-

Four jars working at the same time

-

Transmission mode:

-

Gear drive,motor direct connection

-

Grinding jar volume(ml):

-

50-500ml

-

Max continue time:

-

72H(Timing 0-9999h)

Product Paramenters

Universal Wheel Stone Machine Seed Rock Sample Sale Mills Battery Research Ultra Fine Grinding Mill For Laboratory Pulverizer

|

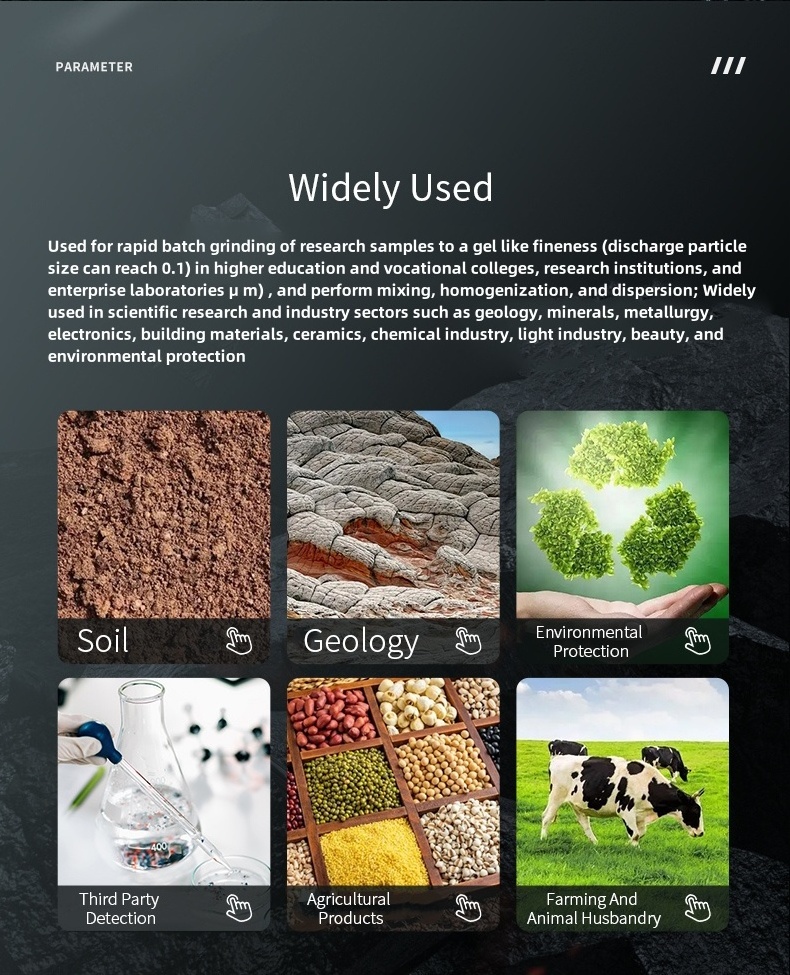

Application

|

Pulverizing, Mixing, Homogenizing, Colloidal Grinding, Mechanical Alloying, Mechanical Chemistry

|

|

|

|

Field of Application

|

New Energy, Geology/Metallurgy, Glass/Ceramics, Engineering/Electronics, Building Materials, Environment/Recycling, Agriculture,

Chemistry, Biology, etc |

|

|

|

Sample Characteristics

|

Soft, Hard, Brittle, Fibrous - dry or wet

|

|

|

|

Pulverization Principle

|

Impact, Friction

|

|

|

|

Maximum SampleSsize

|

< 5 mm, soil < 10 mm

|

|

|

|

Final particle size *

|

For colloidal milling, output < 0.1 µm

|

|

|

|

Number of Grinding Platforms

|

4 units

|

|

|

|

Grinding Method

|

Dry, wet, vacuum, atmosphere-protected grinding possible

|

|

|

|

Material of Grinding Jar

|

Stainless steel, tungsten carbide, zirconia, alumina, silicon carbide, silicon nitride, polyurethane, nylon, PTFE, onyx

|

|

|

|

Ratio Setting

|

1::2

|

|

|

|

Operating Modes

|

3 types: unidirectional, alternating forward and reverse, multi-stage

|

|

|

|

Programs Can Be Stored

|

15pcs

|

|

|

|

Time Setting

|

Intelligent screen digital setting, running/stopping time: 0-9999 minutes

|

|

|

|

Power Failure Protection

|

Power failure protection memory self-start function

|

|

|

|

Model

|

ZQM-2L

|

ZQM-4L

|

|

|

Grinding Jar Volume

|

50-500ml

|

50-1000ml

|

|

|

Vacuum Jar Volume

|

50-250ml

|

50-500ml

|

|

|

Revolution Speed

|

5-400r/min

|

|

|

|

Rotation Speed

|

10-800r/min

|

|

|

|

Power(Watts)

|

0.75KW

|

|

|

|

Voltage & Frequency

|

Single Phase,220V/50Hz

|

|

|

|

Dimensions (WxDxH)

|

710x 490 x 630mm

|

|

|

|

Weight

|

98kg

|

100kg

|

|

Products Description

Hot Searches