- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DESEN

-

Dimension(L*W*H):

-

2245*940*718(mm)

-

Weight:

-

3600kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

double roller crusher

-

The Machines classification:

-

Crushing Line

-

Color:

-

Customizable

-

Keyword:

-

Mine Double Roll Crusher

-

Installation:

-

Under Technical Guidance

-

Spare parts supply:

-

Lifelong Provide

-

Max feeding size:

-

16mm

-

After sale Service:

-

Life Time

-

Test&Installation:

-

Under Enginees Guidence

-

Certification:

-

ISO9001:2008

Quick Details

-

Application:

-

Ore

-

Capacity(t/h):

-

2.3-2.5tph

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

DESEN

-

Dimension(L*W*H):

-

2245*940*718(mm)

-

Weight:

-

3600kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

double roller crusher

-

The Machines classification:

-

Crushing Line

-

Color:

-

Customizable

-

Keyword:

-

Mine Double Roll Crusher

-

Installation:

-

Under Technical Guidance

-

Spare parts supply:

-

Lifelong Provide

-

Max feeding size:

-

16mm

-

After sale Service:

-

Life Time

-

Test&Installation:

-

Under Enginees Guidence

-

Certification:

-

ISO9001:2008

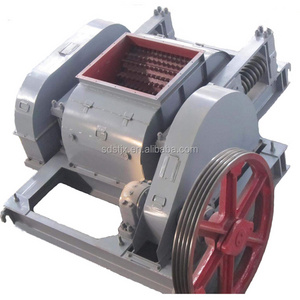

Double rollers crusher

Description

Double Roller Crusher(or Roller Crusher) is used for middle crushing and fine crushing of all kinds of ores and rocks under mid-hardness in mine, chemical industry, cement, building materials and other industrial sections. Roller crusher has simple structure and can be operated conveniently. Ideal product size depends on adjusting space between two rollers.

Feature

1 compact structure, light weight and small dimension

2 easy operation

3 good seal to reduce the leak of the dust, environment friendly

4 high efficiency but low power consumption

5 high crushing ratio, finished size adjustable

Working principles of Double Roller Crusher

Double Roll Crusher is made up of two cylindrical rolls which are installed horizontally. The two rolls rotate in different directions, materials fall on top of the rollers and enter crushing chamber under the action of roll surface friction to be crushed by the rollers, and the final product is discharged from outlet. The crushing process is continuous. Roller crusher has strong discharging force, so even wet materials can also be discharged.

Application

Double teeth roller crusher is widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so on. It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, etc.

Package

Export packing or as request of customers

Our Services

Pre-sale services:

We will provide you with the prior plan, process flow design and production equipment in line with your special

needs.

Sale services:

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

After-sale services:

We will regularly return visit to customers for establishing a long-term and friendly relationship.

Service Commitment

We provide one-year warranty to make sure your machine work well. We have spare parts of the very machine in stock all the time which means the replacements can be sent to you timely.

Our Client Visit

On-site Working

Our company

Xi'an Desen Mining Machinery Equipment Co., LTD is a professional developer and manufacturer on Mineral Separation Equipment, Experiment Separation Equipment, and Electrical Control Equipment etc.

Our equipments have exported to many countries like Malaysia, Philippines, India, Ghana,Indonesia, Vietnam, Turkey, Mongolia, somaliland, Lu Wanda,

Sudan, Zimbabwe, Tanzania etc.

FAQ

1. Q: Are you professional? Do you have ever engaged in the implementation of the overseas mining projects?

A: Yes, we have professional mineral separation team in this industry. Our engineers who perennial activities in South-east Asia, Eastern Europe, Africa and so on, they are expert at the Gold ore, Iron ore, Manganese ore, Tantalum & Niobium, Tungsten and other extraction production.

2. Q: Now we plan to make the production line separation and purification of this mineral. How to deal with it? What type of equipment we need to use?

A: According to mineral information and mining conditions from customers, our engineer design the best mineral processing line and the appropriate equipment to meet the specific needs of customers.

3. Q: If we give this order to your company, what kind of service you can offer?

A: First of all, if needed, our engineers will go to your mining site for field investigation to make the best designing scheme.

After the equipment arrived, we will send engineers to stationed in mine site to conduct the construction of the project, the installation and debugging and the staff training and ensuring the production are always working normally.

4. Q: The technology you designed need water? How much water it will need? What will do if there is a water shortage in our mine site?

A: For this kind mineral, we have dry and wet two different mineral separations. Our engineers will choice the best craft and equipments by the actual conditions that ensure the production line working normal in lack water or less water condition.

5. Q: What promises do you have about the quality of the equipment?

A: Warranty Time: one year. Meanwhile, we will provide a list of consumable parts, and can priority to provide you with adequate vulnerable parts.