- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Garment

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bangzheng Machinery

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

4500 KG

-

Features:

-

Automatic Feeding System

-

X axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Y axis servo motor:

-

For Japanese Panasonic servo drive motor

-

T axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Z axis servo motor (vibration axis):

-

For Japanese Panasonic servo drive motor

-

Control System:

-

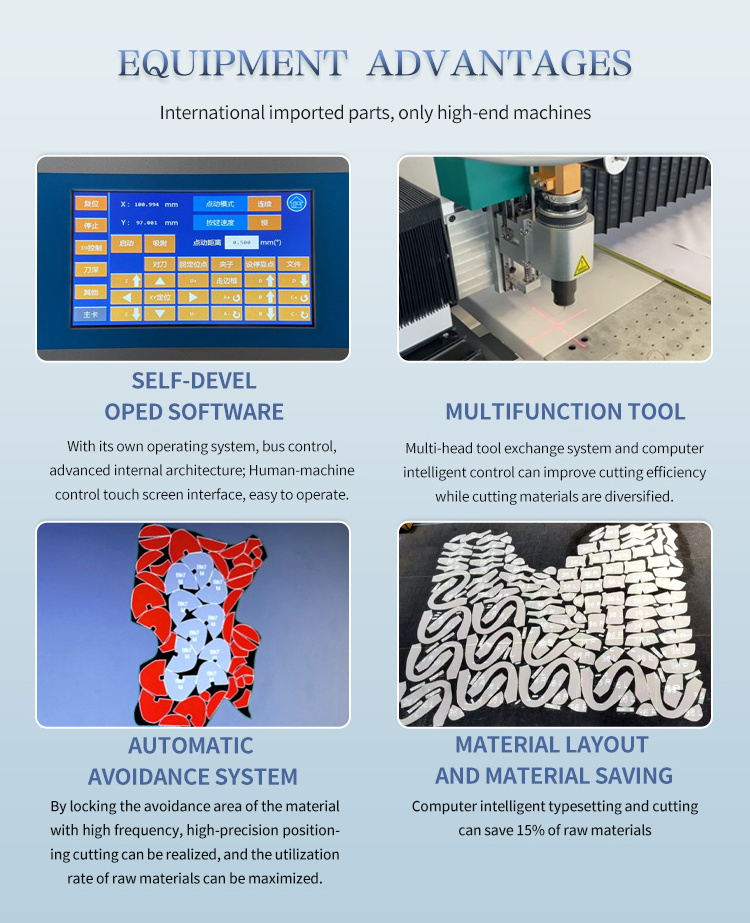

Independent research and development

-

sensor:

-

Import Omron

-

guide:

-

Taiwan PMI

-

drag chain cable:

-

German igus

-

Vacuum adsorption turbo pump:

-

Golden Bridge

-

Head hydraulic buffer:

-

For Japan imported SMC

Quick Details

-

Production Capacity:

-

5000 Sets/year

-

Voltage:

-

220-380V

-

Marketing Type:

-

New Product 2023

-

Application:

-

Garment

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bangzheng Machinery

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

4500 KG

-

Features:

-

Automatic Feeding System

-

X axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Y axis servo motor:

-

For Japanese Panasonic servo drive motor

-

T axis servo motor:

-

For Japanese Panasonic servo drive motor

-

Z axis servo motor (vibration axis):

-

For Japanese Panasonic servo drive motor

-

Control System:

-

Independent research and development

-

sensor:

-

Import Omron

-

guide:

-

Taiwan PMI

-

drag chain cable:

-

German igus

-

Vacuum adsorption turbo pump:

-

Golden Bridge

-

Head hydraulic buffer:

-

For Japan imported SMC

Product Description

|

clipping height

|

|

1-11 cm

|

|

|

|||

|

Effective cropping width

|

|

1700mm

|

|

|

|||

|

Effective cutting length

|

|

Automatic feeding unlimited length

|

|

|

|||

|

Automatic spreading length

|

|

16.8m spreading table (total working length 24m)

|

|

|

|||

|

Way of transporting the knife

|

|

Reciprocating vibrating knife transport

|

|

|

|||

|

cutting speed

|

|

0-60m/min

|

|

|

|||

|

Cutting knife grinding

|

|

Double wheel counter-rotating grinding

|

|

|

|||

|

Adsorption method

|

|

Frequency conversion vacuum constant pressure control mode

|

|

|

|||

|

safety devices

|

|

automatic induction

|

|

|

|||

|

using electric

|

|

Three-phase AC380V/50Hz/25Kw

|

|

|

|||

|

operation panel

|

|

touch control panel

|

|

|

|||

|

clipping parameters

|

|

Input LAN, USB

|

|

|

|||

|

Device weight

|

|

About 4500Kg

|

|

|

|||

|

Other functions

|

|

Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed

|

|

|

|||

|

operating system

|

|

Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping

areas (supports removal of repeated lines), automatic multi-layer cutting bed for residual cloth cutting, automatic cloth spreading machine, and air floatation table |

|

|

|||

Product Description:

1. Computer-controlled automatic cutting, no need for printing paper, no need for a large number of cutting workers, to achieve mass production;

2. The pieces cut out by the equipment have high precision, and the lathe workers can sew directly without trimming the pieces, which effectively improves the sewing efficiency of the lathe workers;

3. The cutting bed control software supports multi-source data formats: it can directly receive common data clothing design typesetting software;

4. The unique algorithm and motion control technology realize the seamless connection between straight lines and arcs, and the cutting precision is high;

5. The equipment adopts automatic sharpening technology, and the sharpening time can be designed according to the characteristics of the fabric, effectively prolonging the service life of the cutting knife;

6. There is no need to print and store paper plates, the reuse rate is high, and the plate making management is convenient;

7. The replacement of consumables is convenient and the replacement cost is low;

8. High degree of automation and simple operation.

Product advantages

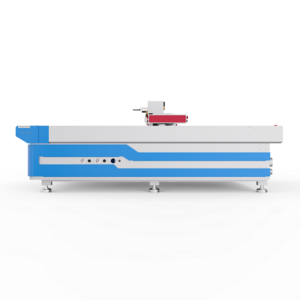

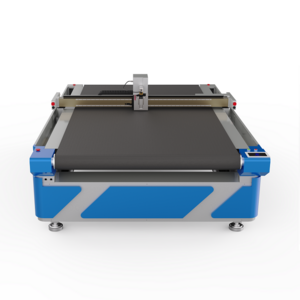

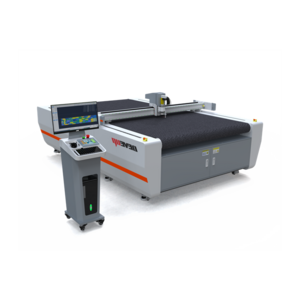

Introduction to multi-layer cutting machine

Product parameters

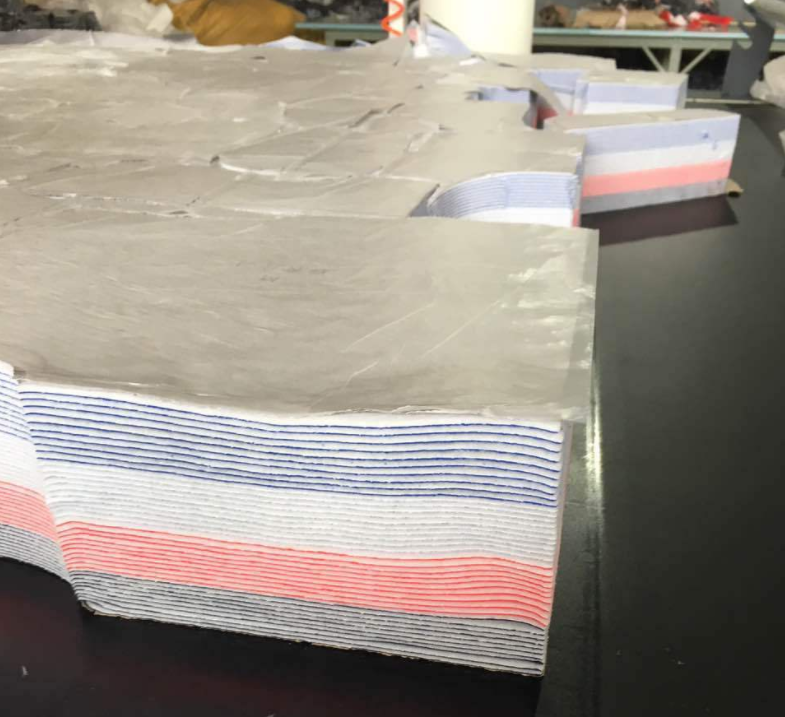

product display

Scenario shows

Enterprise honor

Packing and shipping

FAQ

Q: Is it easy to operate this machine for the first time?

A: We will send you English manual and guide video, it can teach you how to operate the machine. If you still can't learn how to use it, we can talk by phone, email or other contact methods.

Q: What should I do if the machine has a problem at my place?

A: If the machine has any problem under "normal use", we can send you the parts for free during the warranty period.

Q: What's the price and payment terms?

A: EXW, CIF, FOB, CER we all can accept

Payment method: TT/Paypay/LC/Western Union.etc

Q: What is the package?

A: Film packing + wooden case. Fumigation-free plywood cases are also available.

Hot Searches