- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.7mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

28000*5000*2500MM

-

Weight:

-

15.5 kg

-

Marketing Type:

-

Hot Product 2020

-

Raw material:

-

GI OR PPGI

-

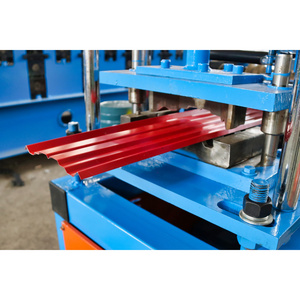

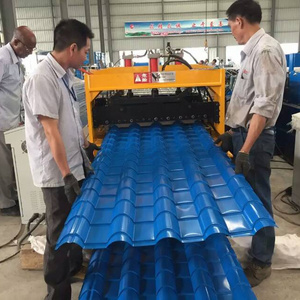

Prodcution Name:

-

European Glazed Roof Tile Cold Roll Forming Machine

-

Roller Stations:

-

16 Stations

-

Under Frame:

-

H-Beam

-

Roller material:

-

45# steel with hard chromed 0.05MM

-

Shaft material:

-

45# steel with processing

-

Shaft Diamter:

-

70MM solid

-

Cutting blade material:

-

Cr12Mov

-

Control system:

-

Taiwan or Japan Famous Brand

-

Local Service Location:

-

None

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

2-4m/min

-

Rolling thinckness:

-

0.3-0.7mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

28000*5000*2500MM

-

Weight:

-

15.5 kg

-

Marketing Type:

-

Hot Product 2020

-

Raw material:

-

GI OR PPGI

-

Prodcution Name:

-

European Glazed Roof Tile Cold Roll Forming Machine

-

Roller Stations:

-

16 Stations

-

Under Frame:

-

H-Beam

-

Roller material:

-

45# steel with hard chromed 0.05MM

-

Shaft material:

-

45# steel with processing

-

Shaft Diamter:

-

70MM solid

-

Cutting blade material:

-

Cr12Mov

-

Control system:

-

Taiwan or Japan Famous Brand

-

Local Service Location:

-

None

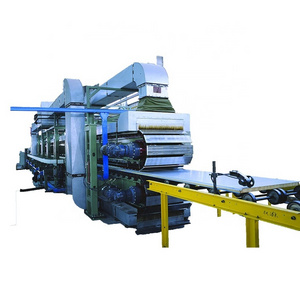

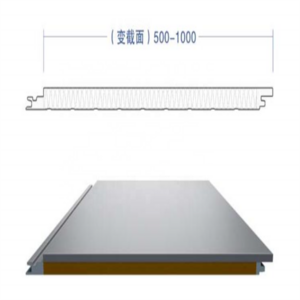

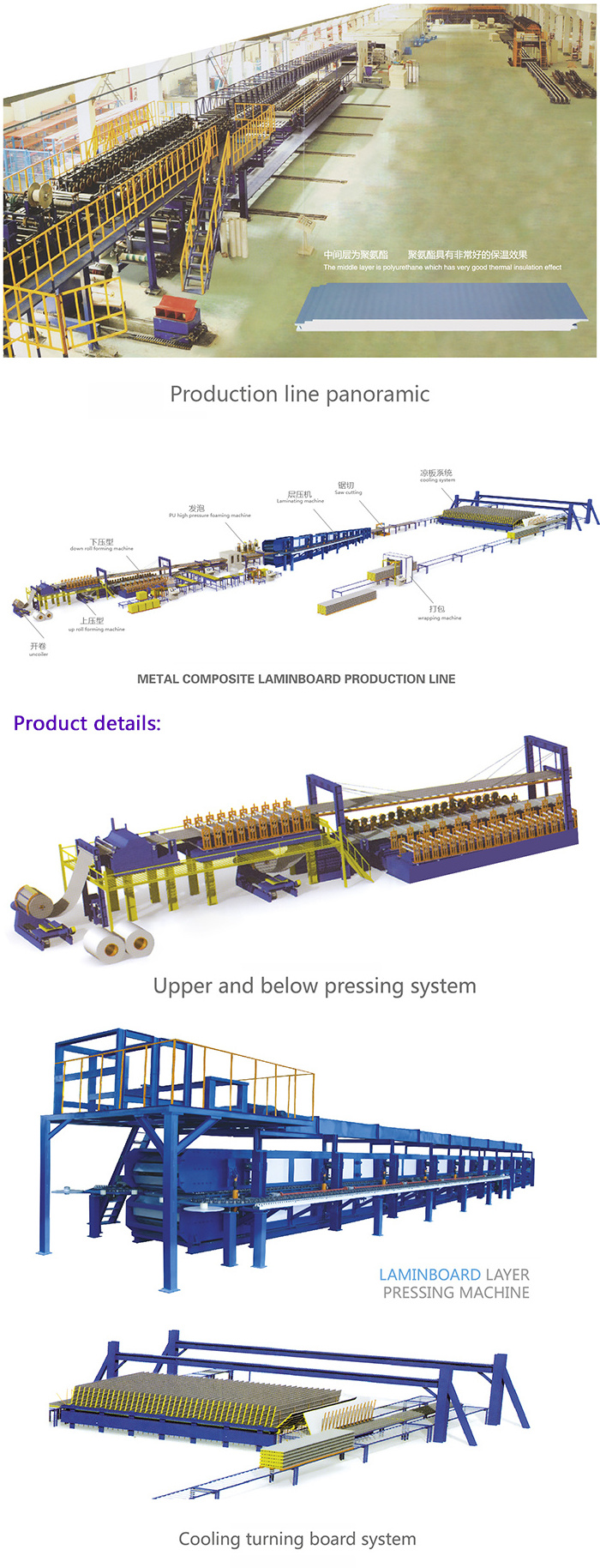

Polyurethane Sandwich Panel Production Line Cold Roll Forming Machine Price

Main Specification of PU Sandwich Panel Production Line:

1) Speed of product line: maximal speed: 6-7/min (approx 2880-3360 m2 per day) (frequency conversion to adjust speed)

2) The dimension the product line: about 120 mX18mX3.5m

3) Total power of the product line: about 40 0 KW (Include the electricity heating 200kw)

4) Single shift can produce 820,000-960,000 m2 (the line can operate 24 hours per day)

5) 2 component Chinese PU foaming machine

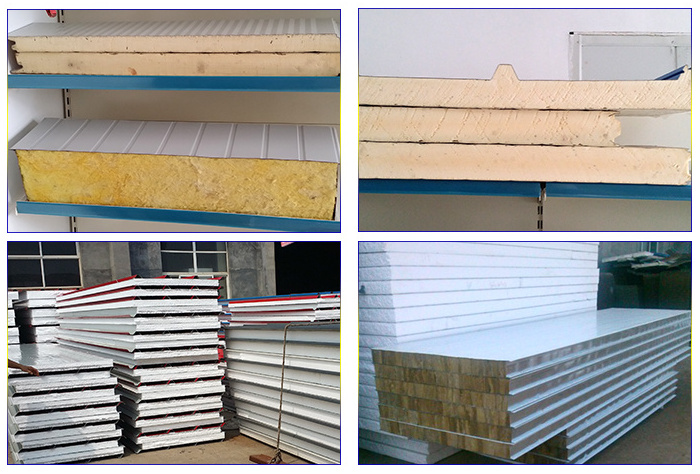

6) The final panel width:1000mm

7) The thickness of the steel sheet:0. 3 -0. 7 mm

8) Core materials: PU

9) Density of the PU panel: 40 -45kg/m3.

10) The length of the double belt: 24m

1. Hydraulic Un - coiler :

| Motor Power: | 3KW |

| Hydraulic Power | 202kw |

| Raw material: | Color steel sheet, Aluminum sheet |

| Inner diameter of coil: | φ500mm-φ600mm |

| Out diameter of coil: | φ1200mm |

| Weight of coil: | 10T |

| Thickness of sheet: | 0.3-0.7mm |

| Width of sheet: | 1250mm |

| Speed of uncoil: | 1.5-12m/min |

| Hydraulic pressure: | 6.3Mpa |

2. Coil car :

| Hydraulic cylinder lift stroke: | up panel 0.5m,down panel 0.5m |

| Coil car stroke: | 0.5m |

| Pressure of hydraulic system: | 6.3Mp |

| Tightening mechanism | Magnetic brake |

Q1. What's your payment terms and delivery time?

A1:

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery.

Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: W

e provide 18 months free warranty and free technical support

for the whole life of any machine.

If the broken parts can't repair, we can send the new parts

replace the broken parts freely, but you need pay the express cost by yourself.

If it is beyond the warranty

period,

we can negotiate to solve the problem, and we supply the technical support for the whole life

of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),

then we can pick up you.