- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Type:

-

Plastic Plywood

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianggong

-

Model Number:

-

Plastic Plywood

-

Product name:

-

Plastic Faced Plywood

-

Key word:

-

Plastic Plywood

-

Title:

-

Customized 15mm Hollow Structure Plastic Plywood vv

-

Usage::

-

Concorete Panels Shuttering Formwork

-

Material:

-

PP

-

Package:

-

Standard package

-

MOQ:

-

1,000 Pieces

-

Weight:

-

18--32 Kg

-

Product Capacity:

-

20000

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Other

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Type:

-

Plastic Plywood

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianggong

-

Model Number:

-

Plastic Plywood

-

Product name:

-

Plastic Faced Plywood

-

Key word:

-

Plastic Plywood

-

Title:

-

Customized 15mm Hollow Structure Plastic Plywood vv

-

Usage::

-

Concorete Panels Shuttering Formwork

-

Material:

-

PP

-

Package:

-

Standard package

-

MOQ:

-

1,000 Pieces

-

Weight:

-

18--32 Kg

-

Product Capacity:

-

20000

Product Description

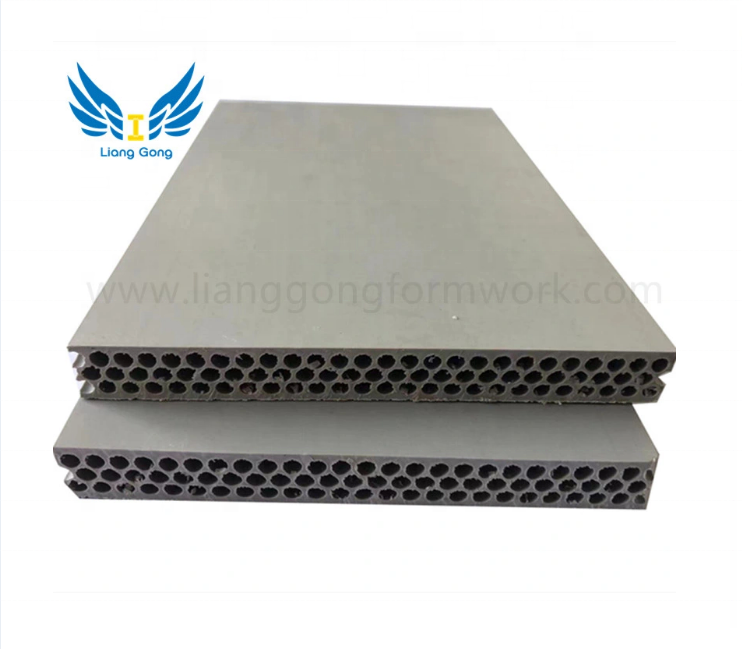

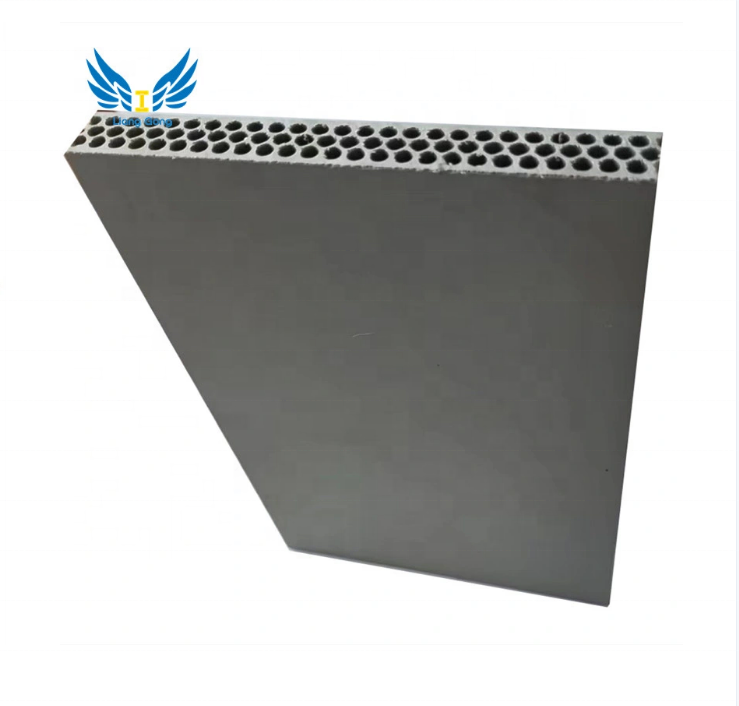

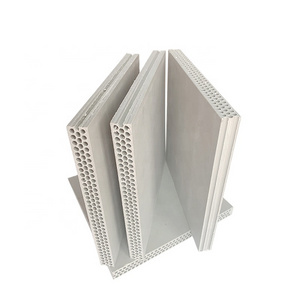

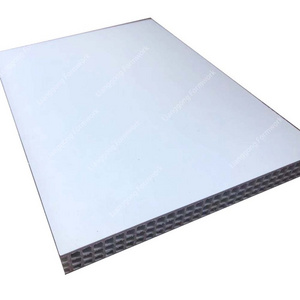

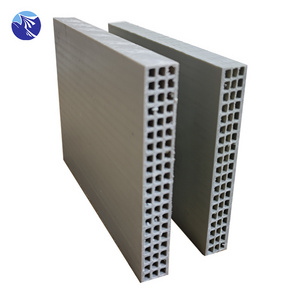

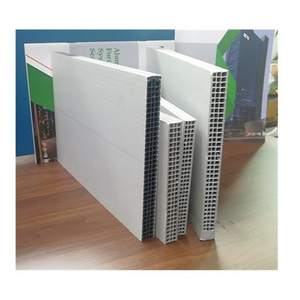

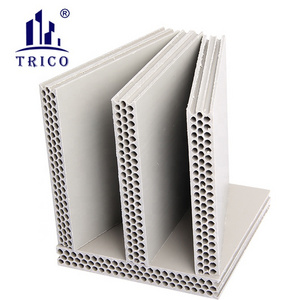

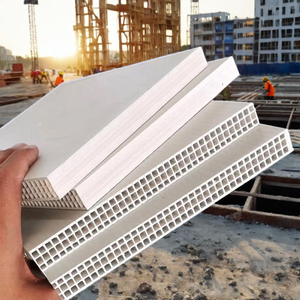

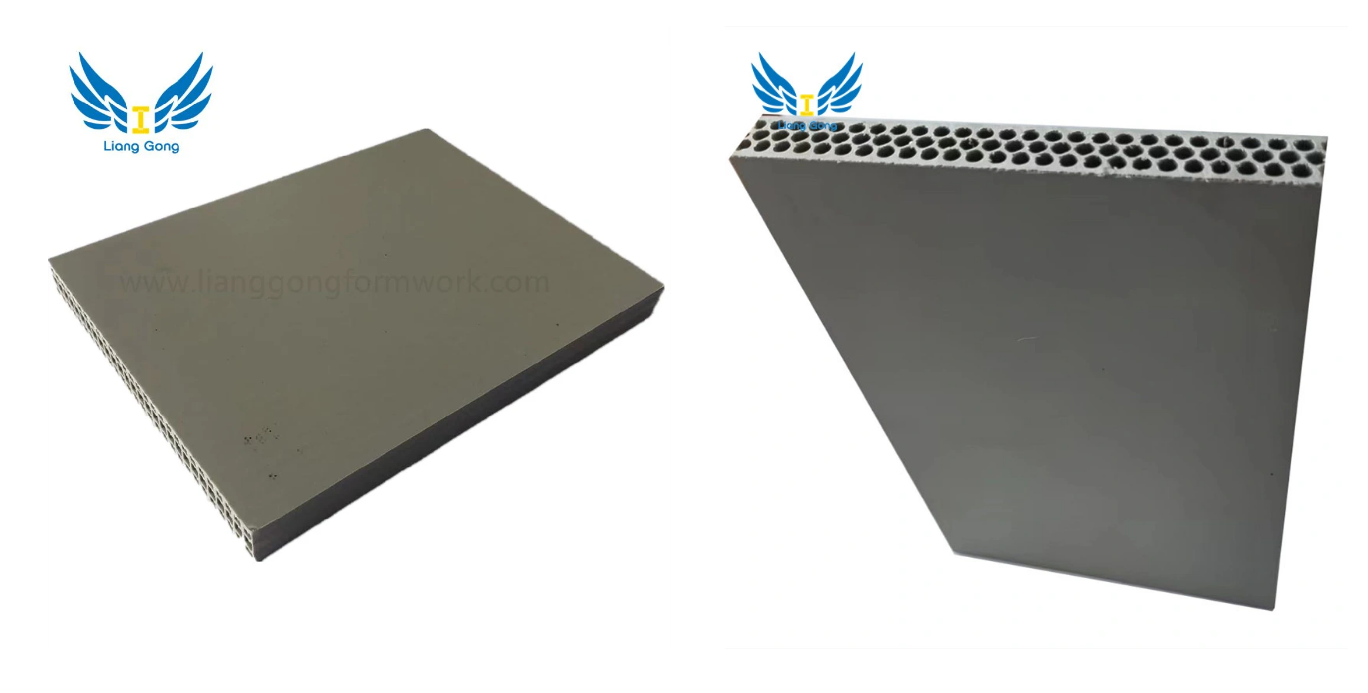

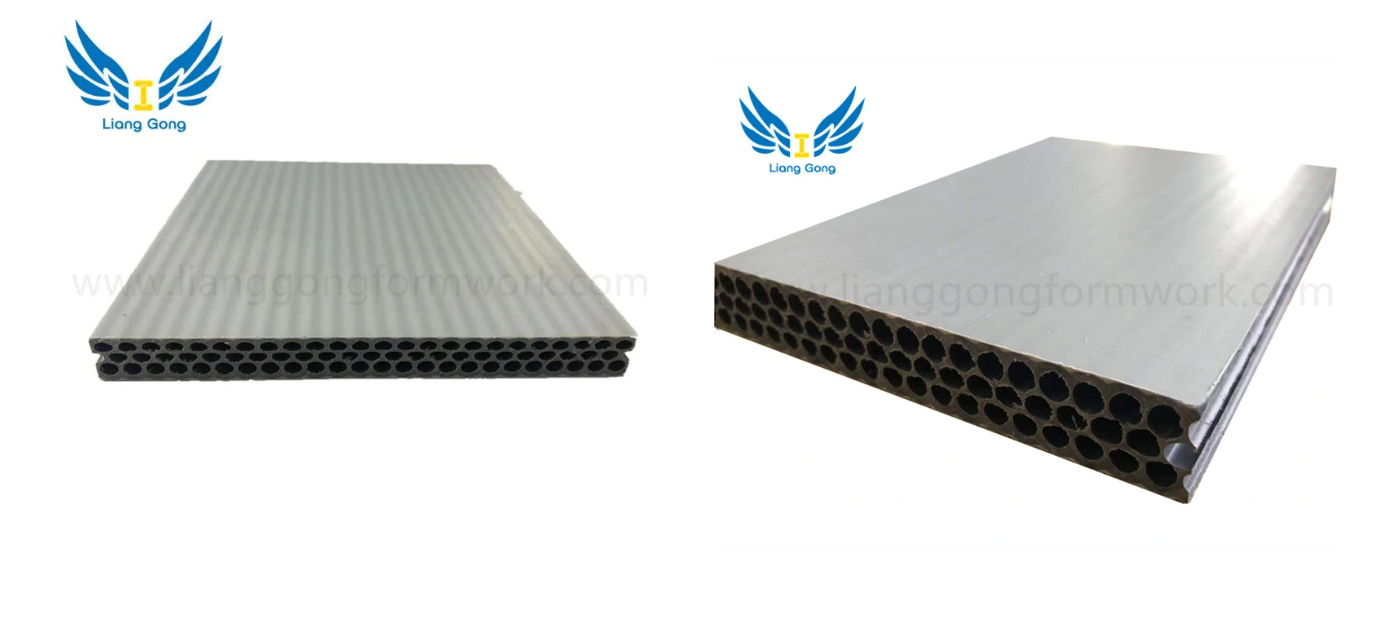

Construction Shuttering Board Hollow Plastic Board

PP hollow building formwork adopts imported high performance engineering resin as the base material, adding chemical additives such as toughening, strengthening, weather proof, anti-aging, and fire proof, etc., melting and extruding through the special chemical structure restructure technology of Longstar company.

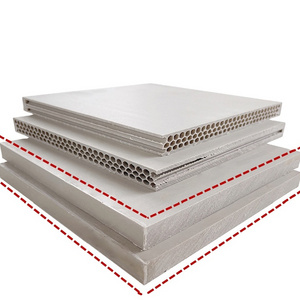

Specification

|

Size

|

Thickness

|

Weight/pc

|

Container

Loading(pc)

|

Container

Loading(pc)

|

|

(mm)

|

(mm)

|

(Kg)

|

20GP

|

40GP

|

|

1220*2440

|

12

|

19±1

|

560

|

1126

|

|

1220*2440

|

15

|

25±1

|

456

|

1026

|

|

1220*2440

|

18

|

29±1

|

400

|

900

|

|

1220*2440

|

20

|

31±1

|

336

|

720

|

Charateristics

1.

Standard specification (mm): 1830*915/2440*1220

2.Reuse more than 60 times

3.No need oil,easily install and remove only tapping formwork can be falled off

4.Waterpoof

5.Bearable temperature:-10-70ºC

6.No expansion,no shrinkage,high strength

7.Anti slip

8.Shorten construction period

9.Glass glue can repair scratch on the surface

10.Rinse with water will be clean

2.Reuse more than 60 times

3.No need oil,easily install and remove only tapping formwork can be falled off

4.Waterpoof

5.Bearable temperature:-10-70ºC

6.No expansion,no shrinkage,high strength

7.Anti slip

8.Shorten construction period

9.Glass glue can repair scratch on the surface

10.Rinse with water will be clean

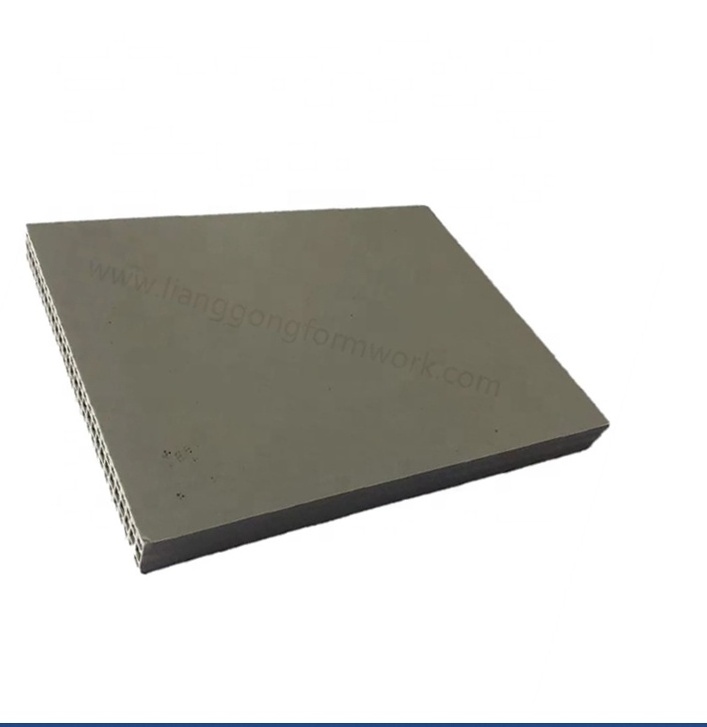

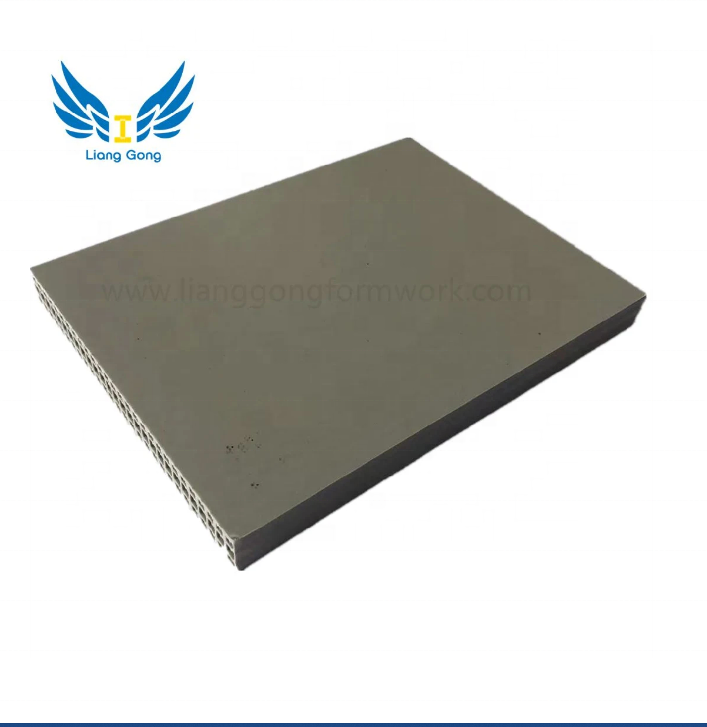

Products Show

Our Company

Customer Photos

1.Consulting, Design and Quotation

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.

Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-Site Instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied throughout the process.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturer.

Q2. What do you do?

A: We design and manufacture formwork and scaffolding products used for pouring concrete structure in the field of housing, multi-story structure, high rise buildings,towers, sports stadiums, bridges, hydro power stations, industrial structures etc.

Q3: Do you provide samples ? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4. What can you do for us?

A.We offer our suggestions, drawings of formwork layout, and quotations to the owners, design institutes, or contractors of the construction projects.

B.We sell our products to the contractors, building companies, material supplier or trading companies.

C.We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D.We provide remote or on-site instruction to the builders.

Q5. What do you need in order to make a brief design and quotation when we have a construction project to be built?

A:Structural drawing and section drawing.

Q6. How long does it take to make a brief design and quotation after we offer the structural drawing?

A: In general, it takes 5~7 days based on specific requirements of construction project.

Q7. How long dose it take to manufacture the products after the signing of contract?

A: In general, it takes 30~60 days based on the type and quantity of products to be produced.

Q8: What is your terms of payment ?

A: Payment<=10,000USD, 100% in advance. Payment>=100,000USD, 30% T/T in advance ,balance before shipment.

Hot Searches